Welder Resume Examples & Guide for 2024

You’re a welder. You solve problems. You join things together.

But when it comes to putting together a winning resume, you’re stuck.

What type of resume does a welder need, anyway?

Whether you’re experienced or just starting your journey in the welding trade, crafting a resume isn’t the easiest of tasks.

But you’re off to a good start! This page will guide you through the entire process of creating a welder resume.

Specifically, we’re going to learn.

- How to write a welder resume that’ll get your phone ringing off the hook

- How to differentiate your welder resume from the other applicants [with top tips & tricks

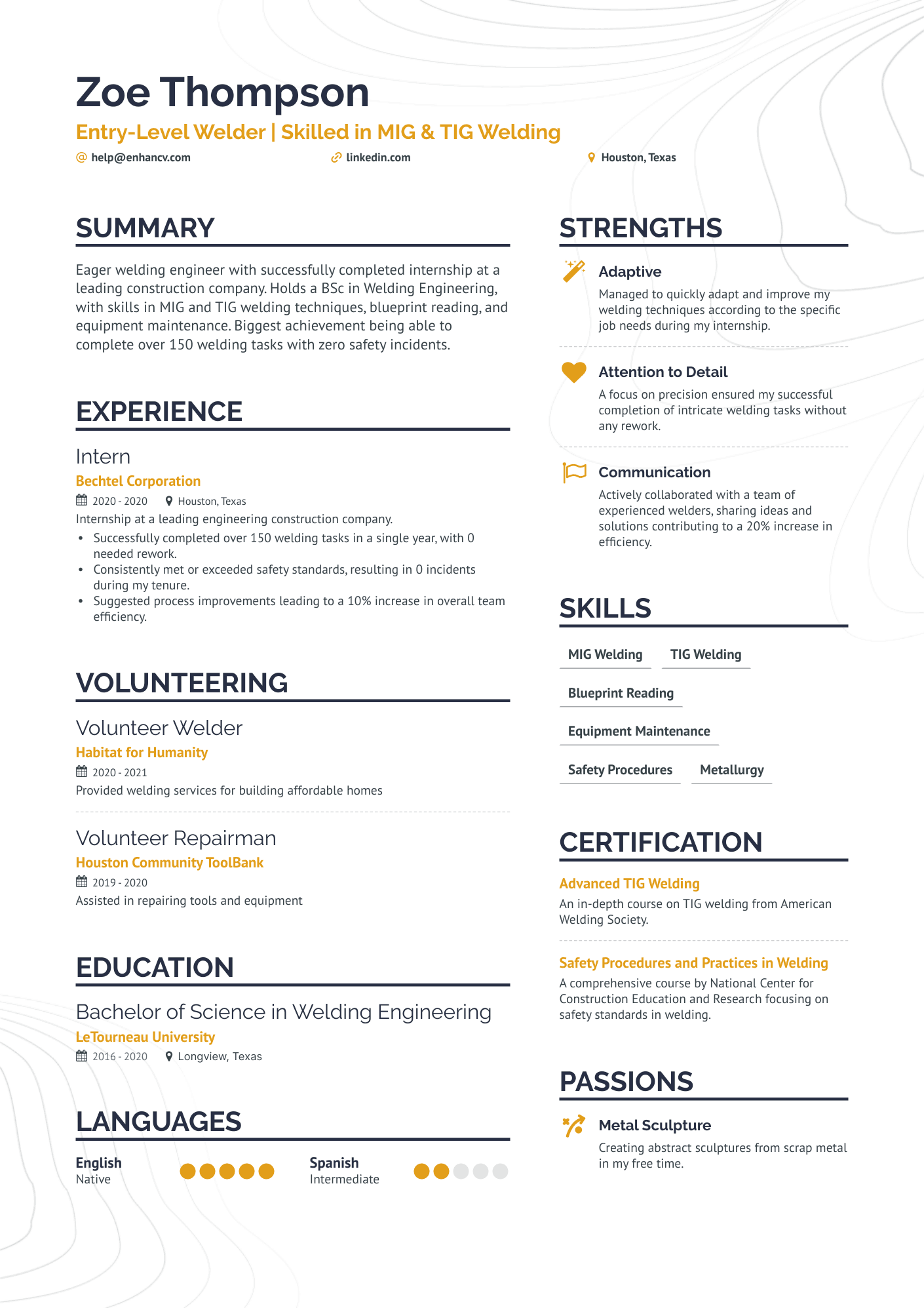

All of this sounds great, but what does a finished welder resume look like?

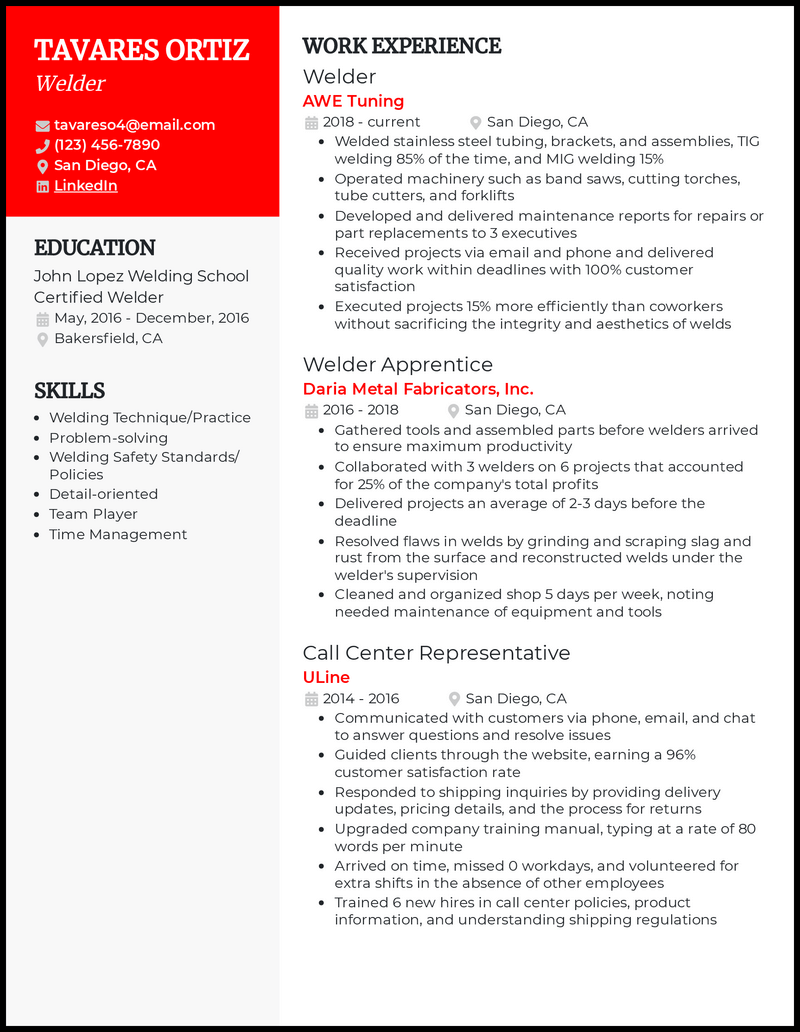

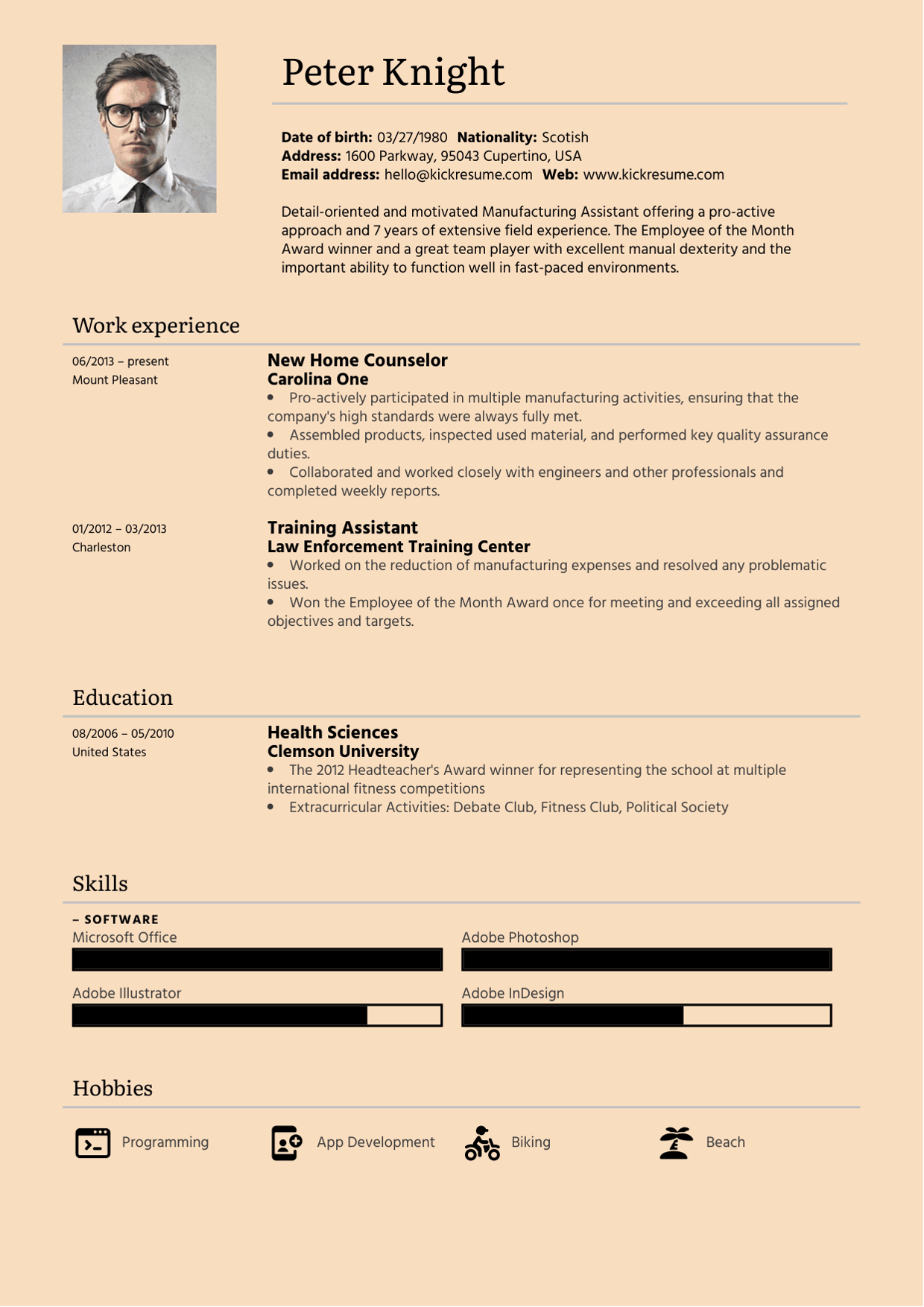

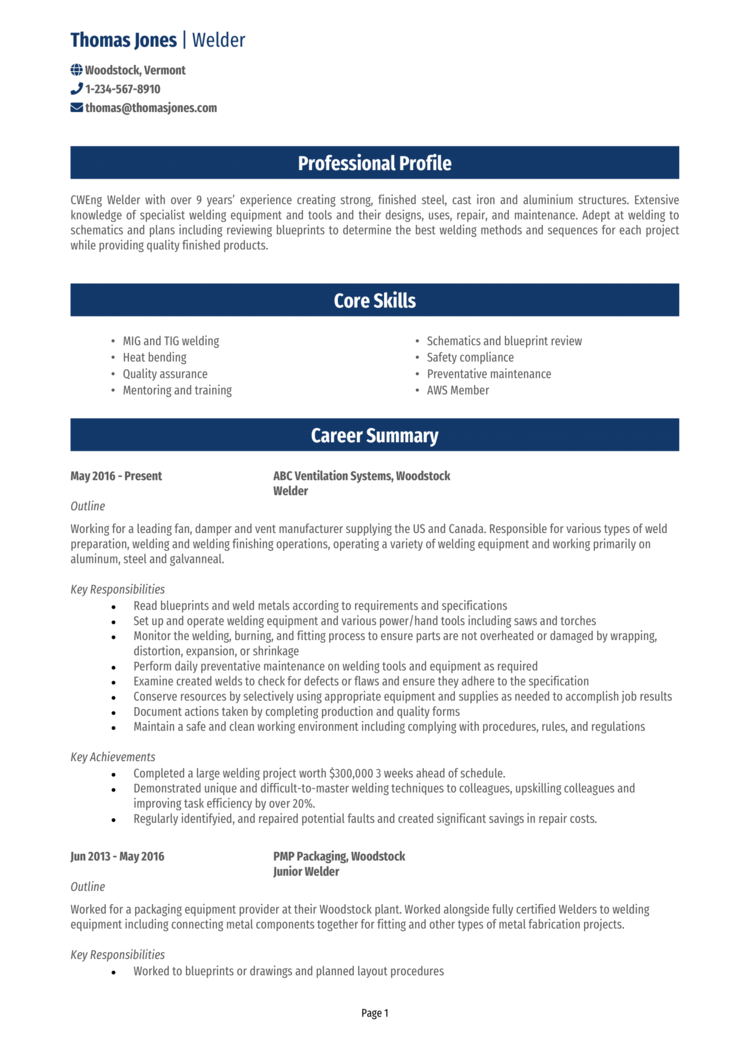

Here’s a welder resume example, created with our very own resume builder:

Looks good, doesn’t it?! Now it’s your turn.

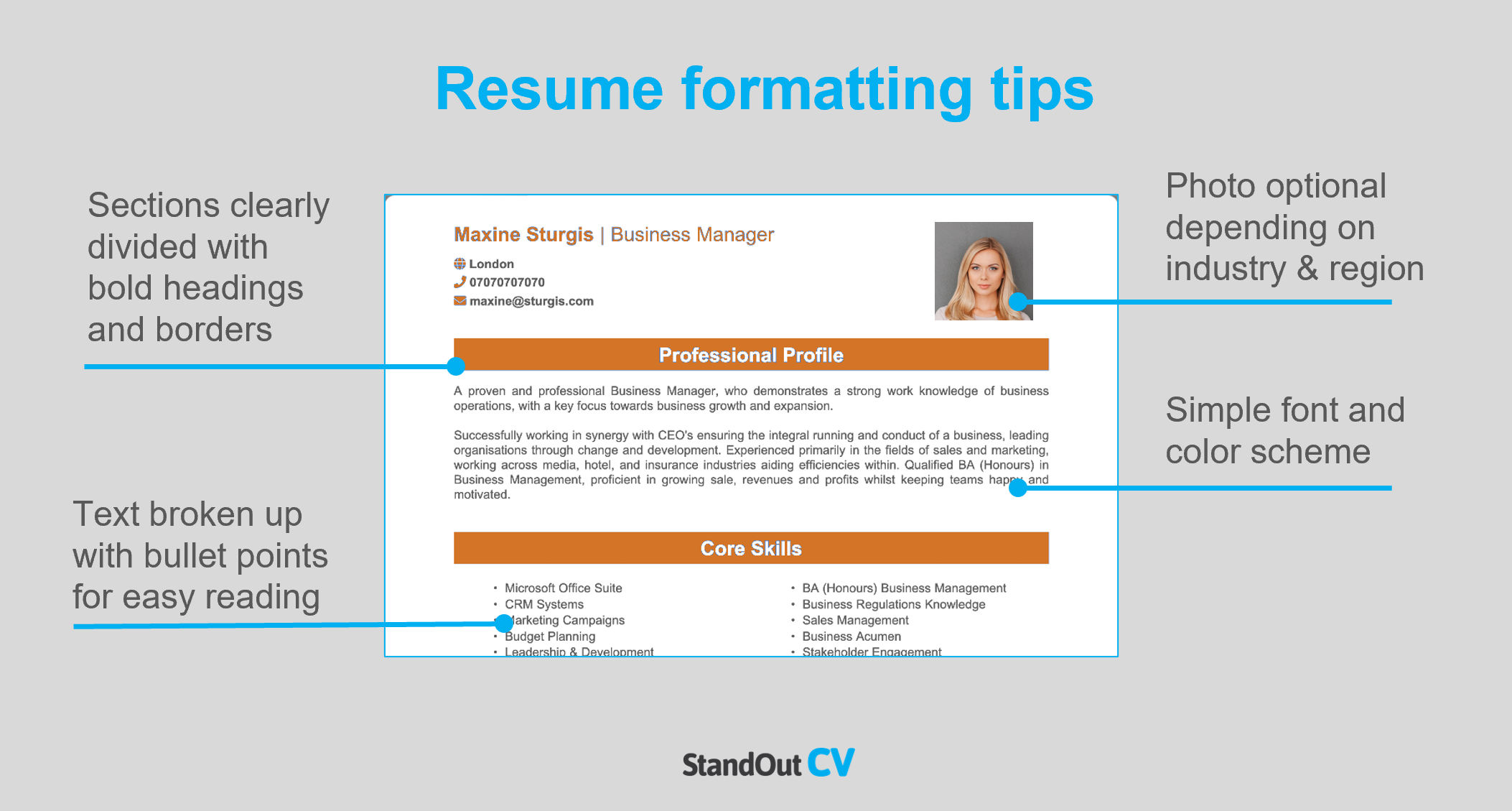

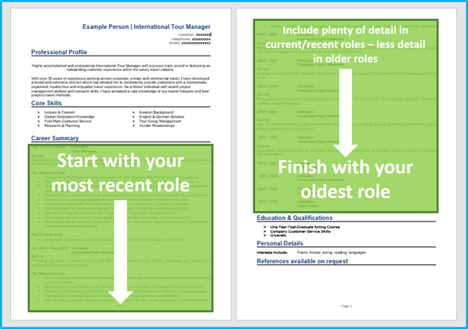

How to Format a Welder Resume

As a welder, you understand the importance of stepping back to assess the job before starting to weld.

Similarly, you should take a step back and choose a format before writing your resume.

This is not a step to skip!

In fact, a well-formatted resume highlights your best qualities and is easier for the recruiter to read.

The most commonly used resume format is “ reverse-chronological ”, and we can see why. As such, it is the one we recommend starting with

Here are two more formats you may want to try:

- Functional Resume - This format is a lot more about your welding skills, rather than your professional experience as a welder. This option is a good choice if you are a highly-skilled welder, but lack the professional experience.

- Combination Resume - As you can guess, a combination resume mixes the “Functional” and “Reverse-Chronological” formats. As such, this format focuses on both skills AND work experience.

Once you’ve settled on your format, it’s time to focus on the resume layout .

Here’s what we recommend:

- Margins - One-inch margins on all sides

- Font - Pick a font that stands out, but is still professional

- Font Size - 11-12pt for normal text and 14-16pt for headers

- Line Spacing - Use 1.0 or 1.15 line spacing

- Resume Length - Keep everything to one page. If you’re having trouble, check out these one-page resume templates .

Use a Welder Resume Template

Microsoft Word is one of the most commonly used programs to create documents.

However, the program is not known for its formatting performance.

We’ve all been there: you create the perfect resume, make one small change, and then the whole thing falls apart.

To skip the headache, use proven and tested resume templates .

What to Include in a Welder Resume

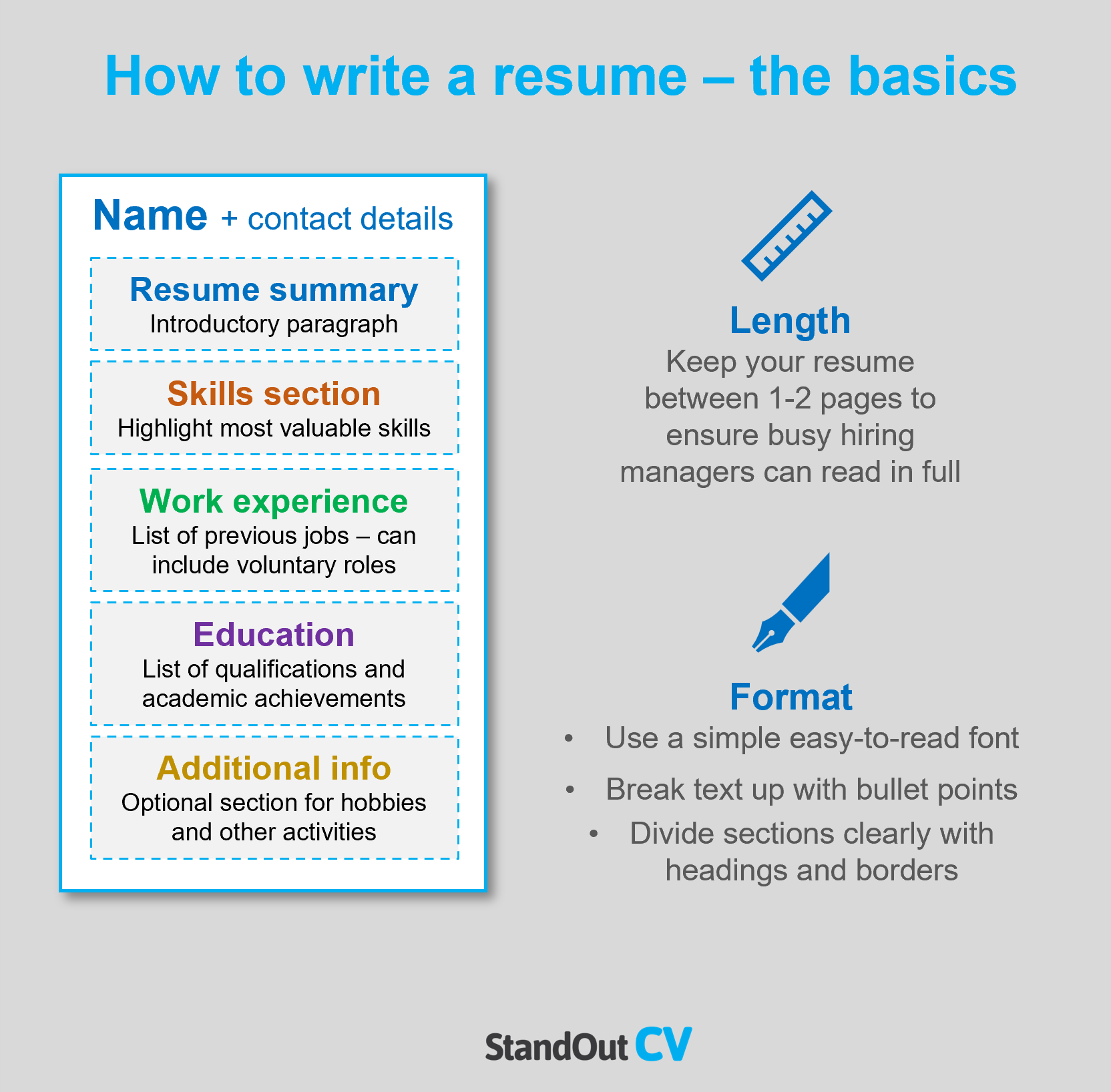

The main sections in a welder resume are:

- Contact Information

- Work Experience

- Certificates

To really impress the hiring manager, add these optional sections :

- Awards & Certification

- Volunteer Experience

For more in-depth information of which sections to use, check out our What to Put on a Resume guide.

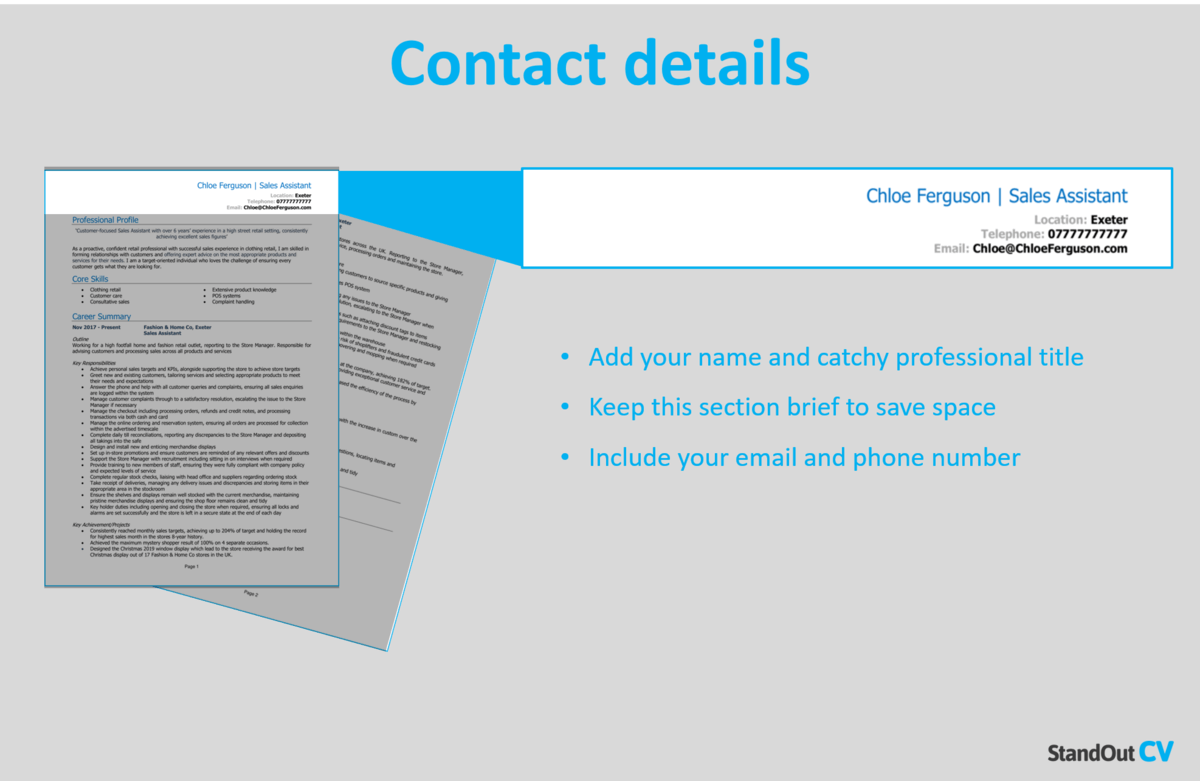

How to Get Your Contact Information Right

Get your contact information wrong, and you can say goodbye to that welding job! Even the best resume can’t escape the pitfalls of an incorrect phone number.

The contact section should include:

- Title - In this case, “Welder” . Keep this professional and specific to the job you’re applying for.

- Phone Number - Double-check, then triple-check this. One tiny mistake can really mess up your chances.

- Email Address - Use a professional email address ([email protected]).

- (Optional) Relevant Social Media - LinkedIn, Quora, etc.

- (Optional) Location - Applying for a job abroad? Mention your location.

- Tim Faking - Experienced Welder. 101-358-6095. [email protected]

- Tim Faking - Welding Master. 101-358-6095. [email protected]

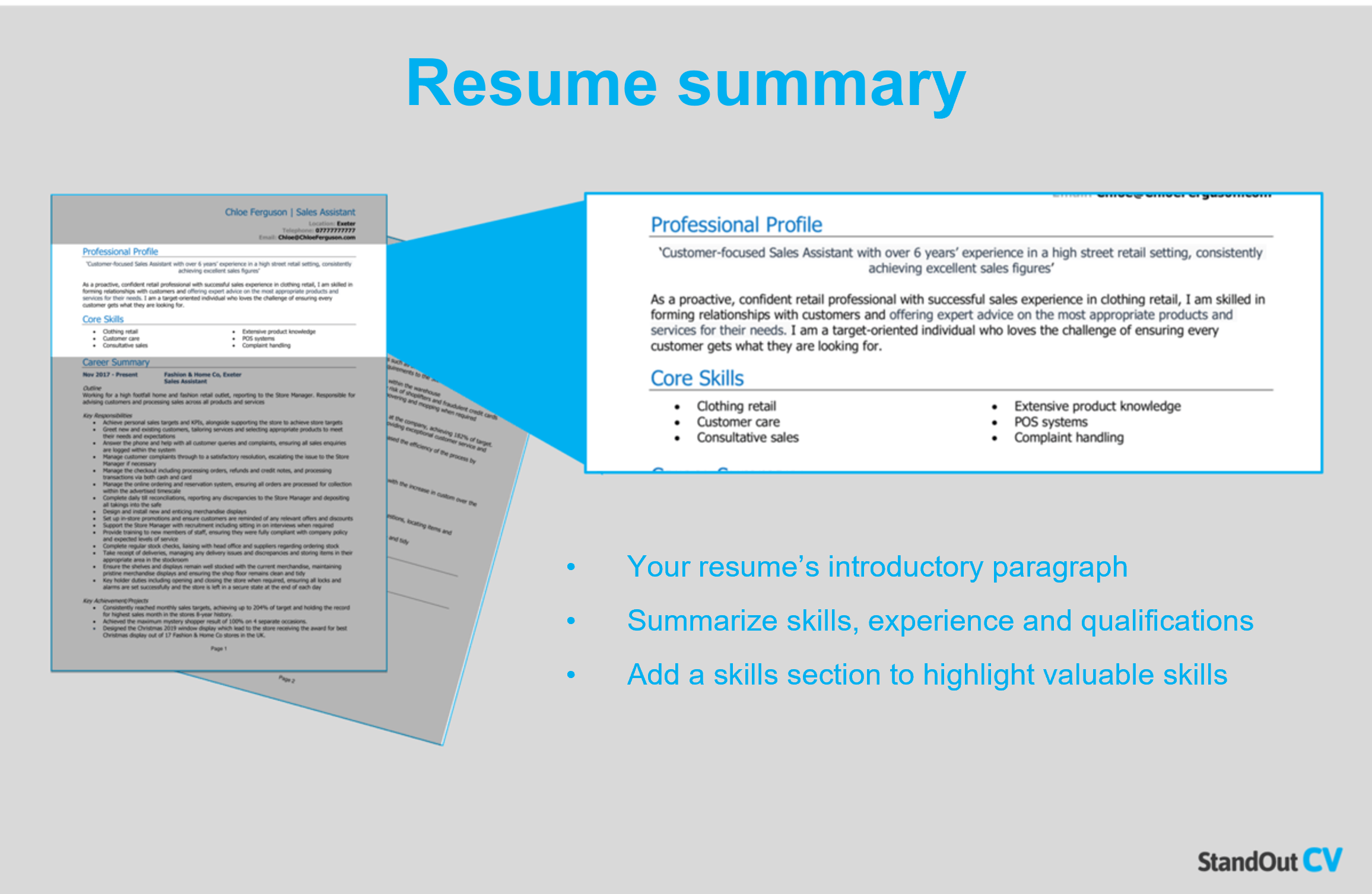

How to Write a Welder Resume Summary or Objective

Here’s a fact for you – studies show that recruiters spend less than 6 seconds on each resume.

On reflection, this isn’t much of a shock, especially when you consider that recruiters typically review resumes by the hundred.

So, always keep this fact in mind when creating your resume.

With that said, what can you specifically do to win the recruiter’s attention?

The answer is simple: use a resume summary or objective .

Essentially, these are short paragraphs that go on top of a resume.

Although similar, the two have their differences.

A resume summary is a 2-4 sentence summary of your welding skills and experiences. You can also talk about your best welding achievements.

- Professional welder with 10+ years of experience in TIG, MIG, stick and flux welding, as well as crane and drill press operation. Capable of reading blueprints and diagrams. Seeking a role as welder at Company X.

A resume objective , on the other hand, is a 2-4 sentence snapshot of your welding goals and aspirations.

- Motivated welder looking for a position at Construction Company X. Passionate about fabricating, repairing, and installing industrial equipment. Experience completing welding projects with speed, accuracy, and to a high-quality standard at College X. Skilled in FCAW, SMAW, GMAW, and Oxy-Fuel welding.

So, which one will land you the job?

As a rule of thumb, welders with work experience should go for with a summary, whereas welders who are new to the trade should go for an objective.

- If you’re having trouble “summing up”, you can come back to this section after the rest of the resume has been written.

How to Make Your Welding Work Experience Stand Out

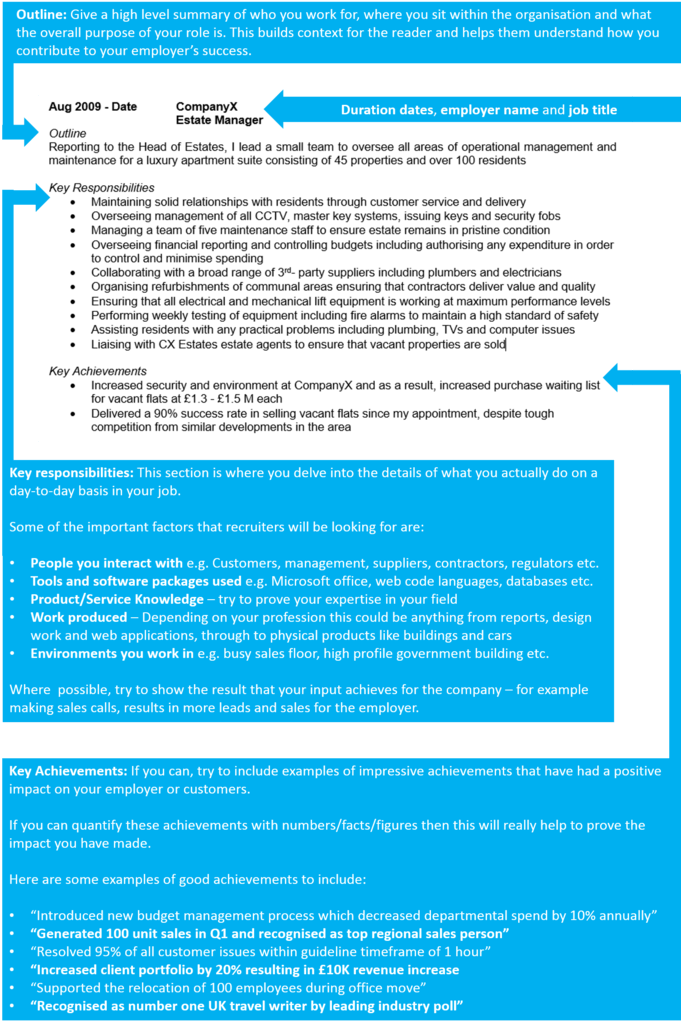

Qualifications are important, but nothing speaks to the hiring manager like relevant work experience. Your work experience section should follow this structure.

Sure, your design skills are super important, but so is your professional experience. Here’s how to structure your work experience section:

- Position name

- Company Name

- Responsibilities & Achievements

Welding Mechanic

Construction X

01/2015 - 03/2020

- Completed a large welding project (worth $400k) 3 weeks ahead of schedule

- Trained 4 junior welders – improving project completion by 12%

- Maintained equipment – saving thousands in repair costs

Now, you may notice the above examples are benefit-driven. Many welders make the mistake of just listing their daily duties, instead of their best achievements.

Instead of saying:

“Welding with time restraints”

“Completed a large welding project (worth $400k) 3 weeks ahead of schedule”

So, what’s the difference between the two?

The second one has that “ wow factor ”. It tells the recruiter that not only can the welder handle large projects, but the welder is great at time management.

What if You Don’t Have Work Experience?

Maybe you’ve recently finished college but haven’t done any paid welding work?

Whatever the reason, don’t worry!

As long as you can show that you’re skilled, you’ll be okay.

But how can you show your skills, when you’ve got no work experience?

Well, create a portfolio.

Here are several ways you can make your own portfolio (and get paid for it):

- Pick up some local gigs

- Ask your friends & acquaintances if they know anyone that needs welding work

- Work on your own side projects that show your talent

Use Action Words to Make Your Welder Resume POP!

Most resumes have the same dull, impact-less words.

And since you don’t want to be like all of the others, we’d recommend avoiding these words as much as possible.

Instead, throw in some power words to stand out from the crowd:

- Conceptualized

- Spearheaded

How to Add a Portfolio to Your Resume

Portfolio sections are added in the same way that you’d add your work experience…

Under a header named “ Portfolio ” or Personal Projects, link to your website (or Behance / Dribble), and list the welding projects you’ve worked on.

Portfolio - jimwelding.com

- Bike - I fixed the frame on my neighbour’s bike, which broke in half after a crash

- Car - I help with the welding on friends demolition derby car

If you don’t have room for a dedicated portfolio section, you can just link to your online portfolio in your contact information section.

How to List Education Right

The next section in any welder resume is your education.

Now, all you need to do here is list your most relevant or recent education, which is typically a welding course.

- Course Type

- College Name

- Years Studied

- GPA, Honours, Courses, and anything else you might want to add

Certified Welder Program

American Welding Society

Relevant Tests : Structural Steel, Petroleum Pipelines, Sheet Metal, Chemical Refinery Welding Industries

Here are a few frequently asked questions on education (and their answers!):

What if I haven’t finished my welding course?

- Whether you’re still learning the trade, or you dropped out, you should mention any welding education.

Should I list my high school education?

- You should list the highest education that is most relevant to the job you’re applying for.

What goes first, education or experience?

- Welding experience always goes first. If you’re just finishing a welding course, then that will have to be first.

Still have some questions? Check out our guide on how to list education on a resume .

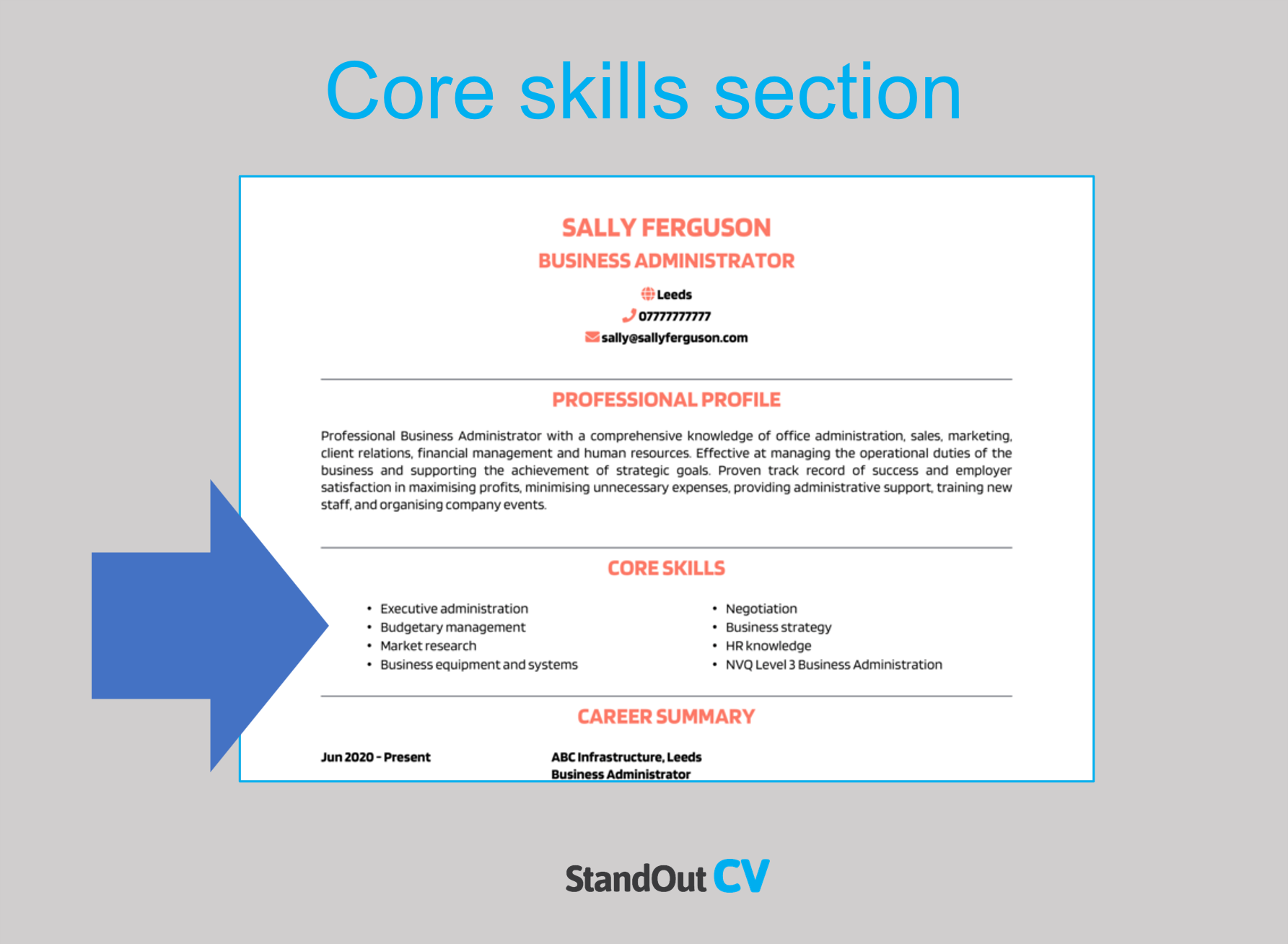

Top 12 Skills for a Welder Resume

It goes without saying, but the hiring manager will want to see that you’re a skilled welder.

With that said, the hiring manager won’t know what you can do, if you don’t mention it.

Imagine this: the hiring manager needs someone who is skilled in flux-core welding, but you forget to mention that you are a professional at that specific skill. In this case, you’ll miss out on getting the job.

Here are some skills a hiring manager would like to see from a welder:

Hard Skills for a Welder

- Oxy-Fuel welding

- Pipe welding

- ISO9001 trained

- 0.35 to 3/32 wiring

Soft Skills for a Welder

- Handling pressure

- Communication

- Time management

- Collaboration

- Problem solving

- Generally, try not to go overboard with the soft skills. Although soft skills are important, they are harder to prove. As such, many recruiters tend to overlook their importance. Just about anyone can say that they can “handle pressure”, but not many people can do flex-core welding to an advanced level.

View our mega-list of 100+ must-have skills in 2023.

Other Resume Sections You Can Include

You’ve talked about your experience, education, and skills.

But is this enough to stand out from the competition?

Well, not quite.

There are a few other sections you can add to take your resume to the next level.

In fact, the following sections can be the difference between getting the job or not...

Awards & Certifications

Did you win a welding award while in education?

Has your welding work been recognised for any awards?

Any award is sure to impress the hiring manager. So if you have won any, be sure to mention them in your resume!

- “Best in Class” - Hinchley Falls College

- “Learning How to Learn” - Coursera Certificate

Are you passionate about welding?

That’s exactly what the hiring manager wants to hear!

Someone who welds on the weekend is more attractive to an employer than someone who only welds when they’re getting paid.

Here are some of the potential examples…

- Blog website about welding

- Side projects, such as building a car

Although very unlikely to be needed in your day-to-day life as a welder, you never know when a language will seen as a benefit. It certainly can’t hurt, can it?!

Make sure to order the languages by skill level, like this:

- Intermediate

Interests & Hobbies

Now, you’re likely thinking, “why does the hiring manager need to know about my passion for fishing?”

Well, they don’t, but it does show that you’re not just a robot who only works.

Recruiters want to see that you’re someone who they will enjoy working with.

Not sure if your hobbies & interests are suitable? Check our guide.

Match Your Cover Letter with Your Resume

So, by now you should have a first-class resume.

But is this enough to beat the rival welders?

One of the easiest ways to fast-track your application to the top of the pile is to include a cover letter with your resume.

A cover letter instantly creates a personal relationship. You see, you’re not just sending the same resume to ten different companies. Instead, you’re showing that you want to work with this company , not just any which will accept you.

Creating a cover letter is also another chance for you to show your achievements and experiences.

If you’re not sure how to create a convincing cover letter, simply follow the steps below

That’s the winning structure, and this is what goes under each section:

Contact Details

Your personal contact information, including full name, profession, email, phone number, location, website (or Behance / Dribble).

Hiring Manager’s Contact Information

Full name, position, location, email

Opening Paragraph

A strong introduction will catch the recruiter’s attention, which will lead to them reading the whole resume. So, mention:

- The position you’re applying for

- Your experience summary and best achievement

Once you’ve got the hiring manager hooked, you can go through the rest of your background. Some of the points you can mention here are:

- Why you’re applying for this specific company

- What you know about the company’s culture

- How your best skills are relevant for the job

- If you’ve worked in similar industries or positions

Closing Paragraph

This is where you:

- Conclude the main points

- Thank the reader for their time

- Finish with a call to action. Something like, “I’d love to discuss further how my experience as an X can help the company with Y”

Formal Salutations

Use a formal closing, such as “ Best regards ” or “ Sincerely. ”

If you need more guidance, be sure to check out our step-by-step guide on how to write a cover letter .

Key Takeaways

Follow the steps in this guide for the best chance at landing your next welding job.

Now, let’s quickly sum up what we have learned:

- Use a reverse-chronological format and the correct layout for your welder resume

- Start your resume with a summary or objective to make your resume more readable

- Talk about your best achievements in your work experience section

- Create a portfolio of your best work. This should include high-quality images

- Write a cover letter to go with your resume

Suggested Reading:

- Best Resume File Type - PDF vs Word [+Templates]

- 9+ Essential Resume Ideas [to Get Your Next job]

- 3 Job-Winning Resume Outline Examples [Download]

To provide a safer experience, the best content and great communication, we use cookies. Learn how we use them for non-authenticated users.

Build my resume

- Resume builder

- Build a better resume in minutes

- Resume examples

- 2,000+ examples that work in 2024

- Resume templates

- 184 free templates for all levels

- Cover letters

- Cover letter generator

- It's like magic, we promise

- Cover letter examples

- Free downloads in Word & Docs

7 Welder Resume Examples Built for 2024

Best for senior and mid-level candidates

There’s plenty of room in our elegant resume template to add your professional experience while impressing recruiters with a sleek design.

Resume Builder

Like this template? Customize this resume and make it your own with the help of our Al-powered suggestions, accent colors, and modern fonts.

Welder Resume

- Welder Resumes by Experience

- Welder Resumes by Role

Welders are in high demand in our modern world. Whether it’s small, custom projects like fire pits or enclosures or whether you’re working on commercial projects like reinforcing steel structures, welding requires training, skill, and attention to detail.

Welding is an art, and your welder resume should reflect your unique skills and strengths that demonstrate how your particular abilities will benefit the company you want to work for in 2024.

We’ve done the research, from entry-level positions to engineering, and we’ve got seven welder resume samples we’re sure you’ll want to look through as you build your career documents for your next position.

And when you’re done, don’t fret because our free cover letter builder will wrap up your job application in a cinch!

or download as PDF

Why this resume works

- For example, your “Skills” section might read, “experienced in various practices and techniques.” Looking through the contents of your resume, it should be easy to see your experience with MIG and TIG in various projects.

- As you write your resume , give some thought to your specialties; list strong job performance and duties that reflect that expertise. Don’t miss our guide on resume skills if you need to jumpstart your brain on the types of skills employers are seeking.

- Even seemingly unrelated work experience has value. For example, skills like customer interaction and training employees demonstrate the ability to problem-solve, work hard, and collaborate with others—all skills translate to a welding position.

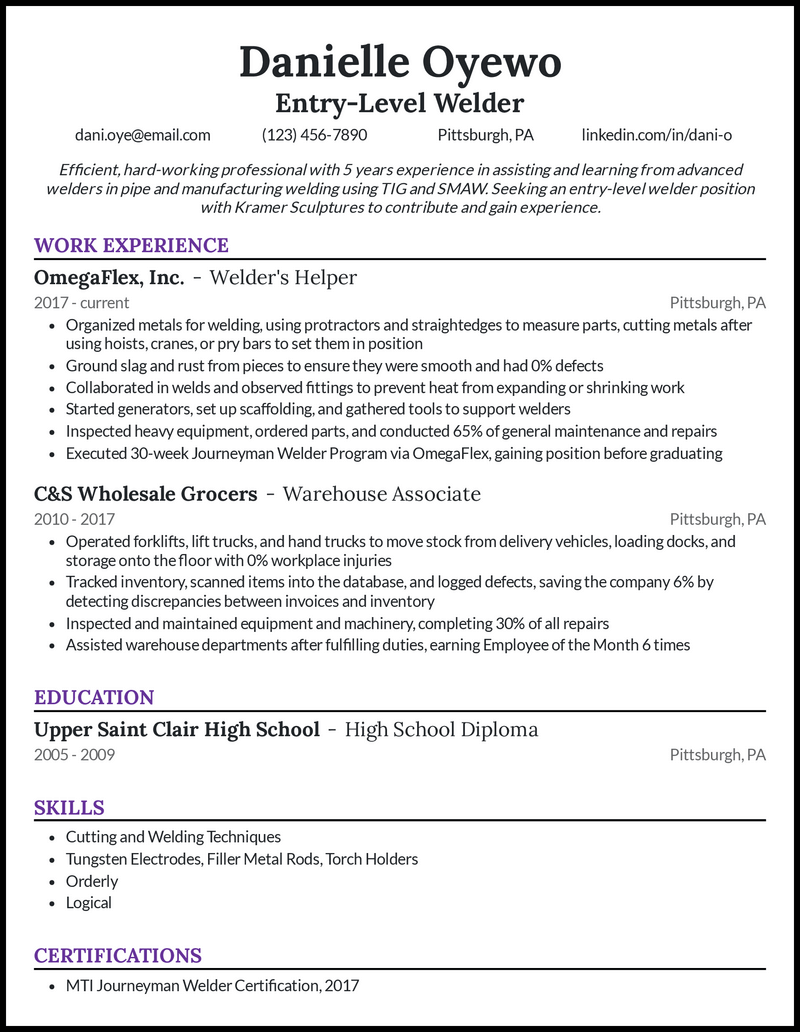

Welder Helper Resume

- Jessie’s welder helper resume deployed the assembler internship to showcase mastery in operating relevant tools and achieving impressive results. You can borrow a leaf from this approach.

Entry-Level Welding Resume

- Use an objective to demonstrate you’re qualified for the position based on your background and responsibilities in different positions.

- Here’s a ton of objective examples to get you started!

- For example, if you landed a job before completing your certification program, mention it. Further explaining the certification and the secured position in your welder cover letter would speak to your value and initiative as an employee!

- It’s beneficial to include previous work history that may not be in the welding field. It can speak to your work ethic and other soft skills like leadership, organization, or attention to detail.

Pipe Welder Resume

- Besides, the highlighted achievements make it easy to follow things that matter most to the hiring team.

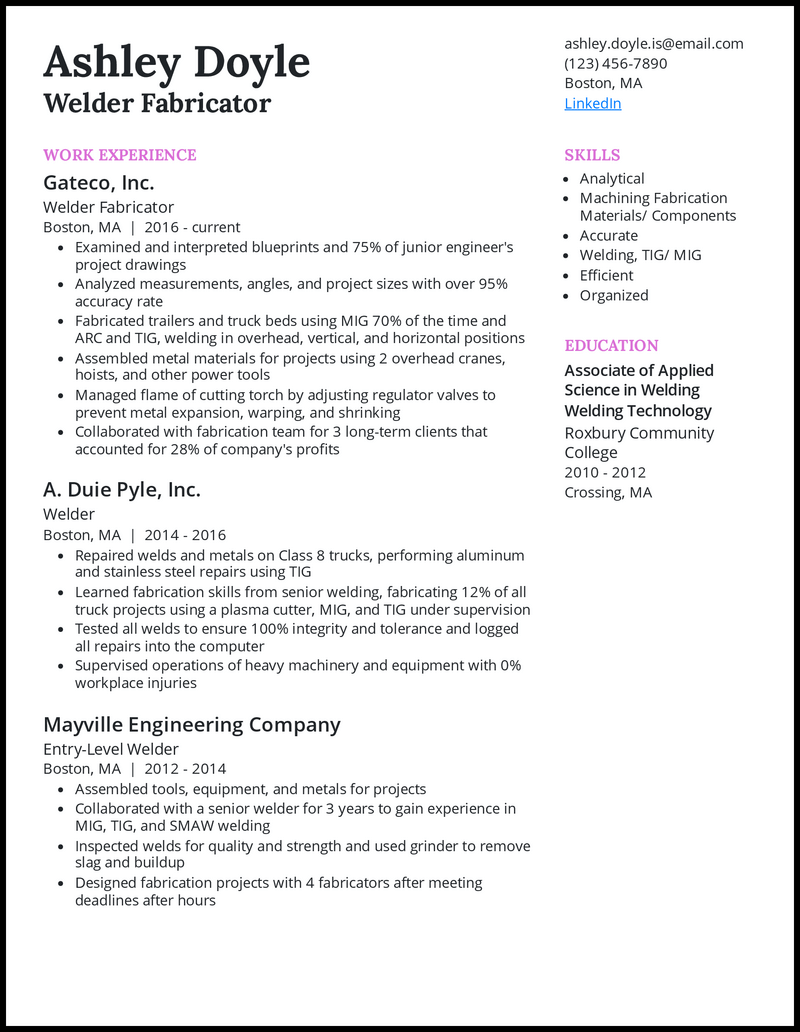

Welder Fabricator Resume

- If you have a certification, keep tabs on whether there’s an expiration date and what’s required to keep it up to date.

- For example, “Learned fabrication skills and contributed to 12% of fabrication projects shows the employer what you’ve achieved concisely yet impressively. Demonstrating your experience with metrics is a building block to advancing your career, and numbers visually back up what you say.

Structural Welder Resume

- Under each position, include similar duties that demonstrate you still depend on and use your core background. You’ll also want to show progression, whether in welding inspections, the metal types you’re working with, or your competency in reading and interpreting blueprints.

- For example, if you saved a company $50k in repairs, a future employer will translate that metric into what you might do for their business!

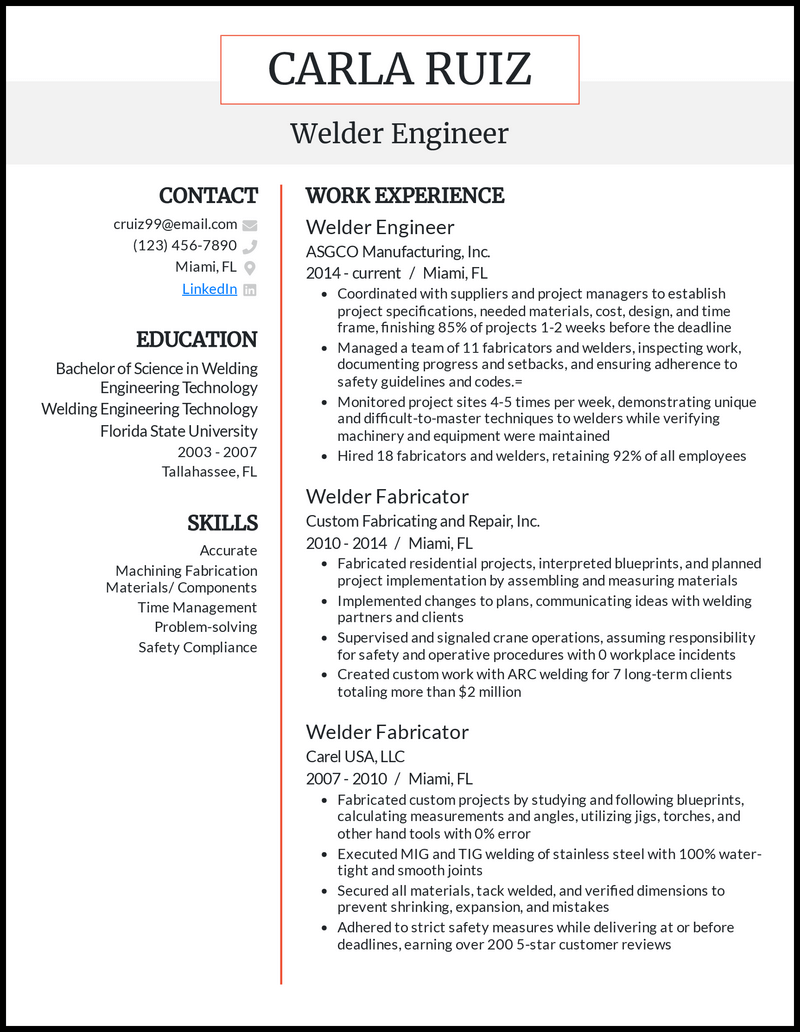

Welder Engineer Resume

- Strong, active verbs demonstrate your ability to problem-solve, make judgment calls, manage and supervise a team, communicate effectively, and work hard in every aspect of your job.

- Do you consistently get things done before the deadline, retain a high percentage of employees over time, or work with a loyal customer base? You may need to do a little math, but adding the metrics will set you apart from other candidates.

- Remember to add your education to your welder engineer resume. A welder engineer will need to prove they have the education, training, and background to do the job.

Related resume guides

- Electrician

- Warehouse Worker

- Landscape Worker

- Construction Worker

How to Create a Welder Resume: Samples and Free Template

Are you an aspiring welder looking to start your dream job? Having a strong resume could be the key to unlocking new opportunities in your trade. Your welder resume is the first impression you make on potential employers, so it needs to provide a compelling recommendation.

The SkillHero app is designed to connect students and skilled trade workers with the resources and opportunities they need to enjoy long-term career success. Whether you're just getting started in the skilled trades or you're looking to advance in your field, SkillHero can help along the way.

Sign up for a free SkillHero account to take the first step towards taking on new welding projects and jobs. Follow this guide to assemble your resume like a welder assembles metal components in the shop.

How to write a welder resume

Here are a few tips to help you craft an impressive welding resume that highlights your skills and experience effectively.

- Highlight your most relevant skills: If you're primarily seeking a specific role, make sure your skills section highlights your most important welding skills. This lets recruiters know that you can fulfill the job's specifications.

- Showcase relevant experience: Along with any relevant work history, emphasize the training, courses, and apprenticeships you’ve participated in, and the skills you’ve gained from them.

- Be yourself in your personal statement: Your short biography is the best place to communicate your unique identity and value. For example, you can mention specific materials you are efficient with or the ambitious goals you hold for your career.

Now let's dive into how to use SkillHero's free resume builder to produce an impressive curriculum vitae in a clean, easy-to-read format.

Add professional data (skills, experience, certifications)

When adding professional welding skills, experience, and certifications to a resume, focus on what's most impressive, most recent, and most relevant for your ideal role. If you have many certifications, be sure to include different types such as safety certifications and skill certifications.

The SkillHero resume builder comes equipped with a database of top industry skills as recommended by experts. Join our community today to get access to our resume builder and all our other resources.

Write a strong personal statement

A strong personal statement is crucial in setting yourself apart from the competition and highlighting your unique skills and qualifications. It's like the cover of a book, and makes the first impression that potential employers or clients will have of you.

To write a powerful personal summary, think about your reason for choosing this trade and what makes you especially valuable to employers. Then, craft a short and direct statement that effectively communicates your qualifications and what you bring to the table.

Sample Personal Summary for a welder : "I have a solid foundation in welding techniques and a passion for mastering the craft. With hands-on experience in both MIG and TIG welding, I am adept at reading blueprints and ensuring precise and high-quality work. My work ethic, attention to detail, and dedication to safety make me a valuable asset to any welding team, and I plan to do great work during my career in the welding trade."

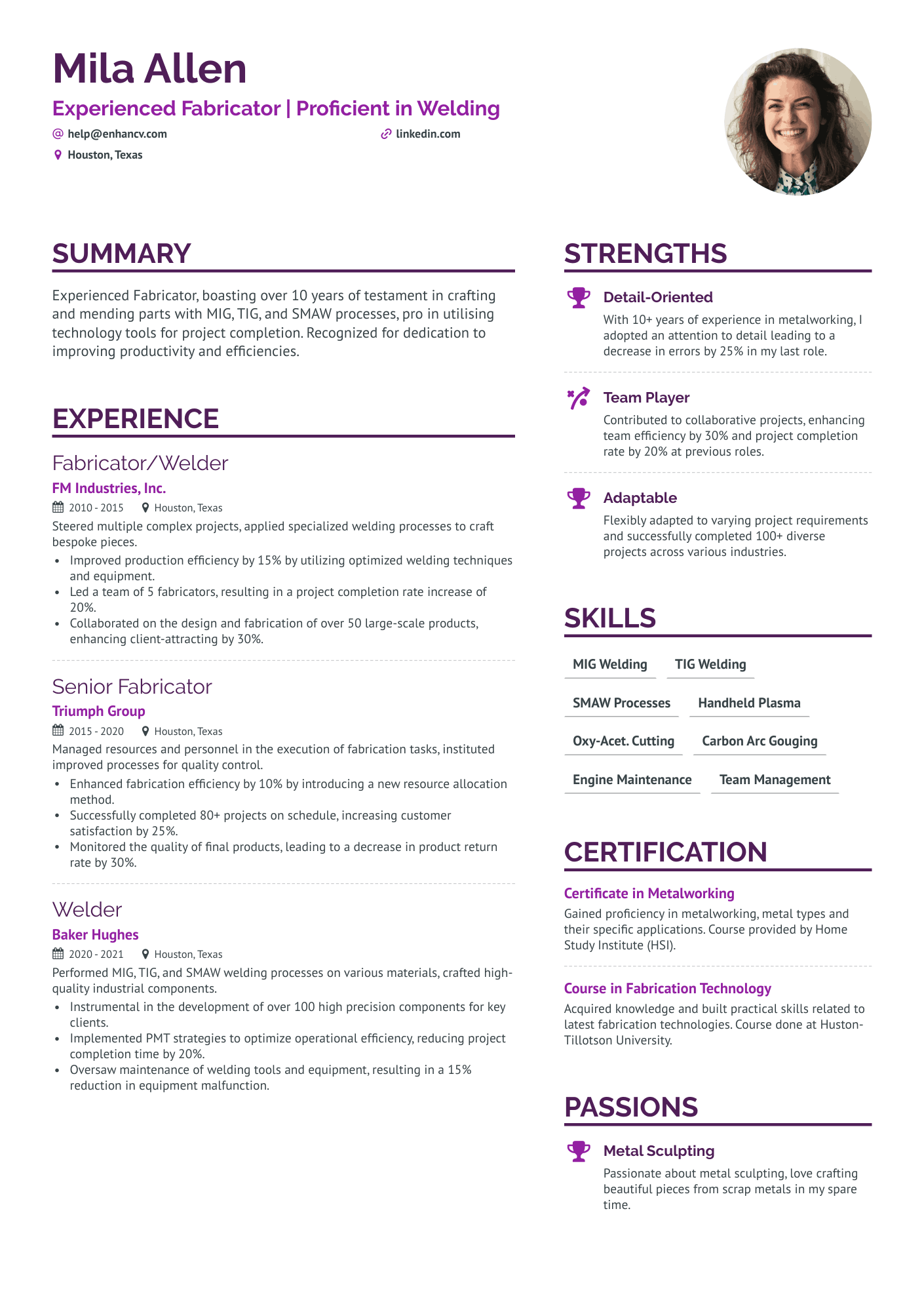

Welder resume examples

A well-crafted resume should highlight your relevant skills, experience, and certifications, while also showcasing your commitment to the trade. We've compiled some welder resume examples to help you create a standout resume that will catch the attention of potential employers.

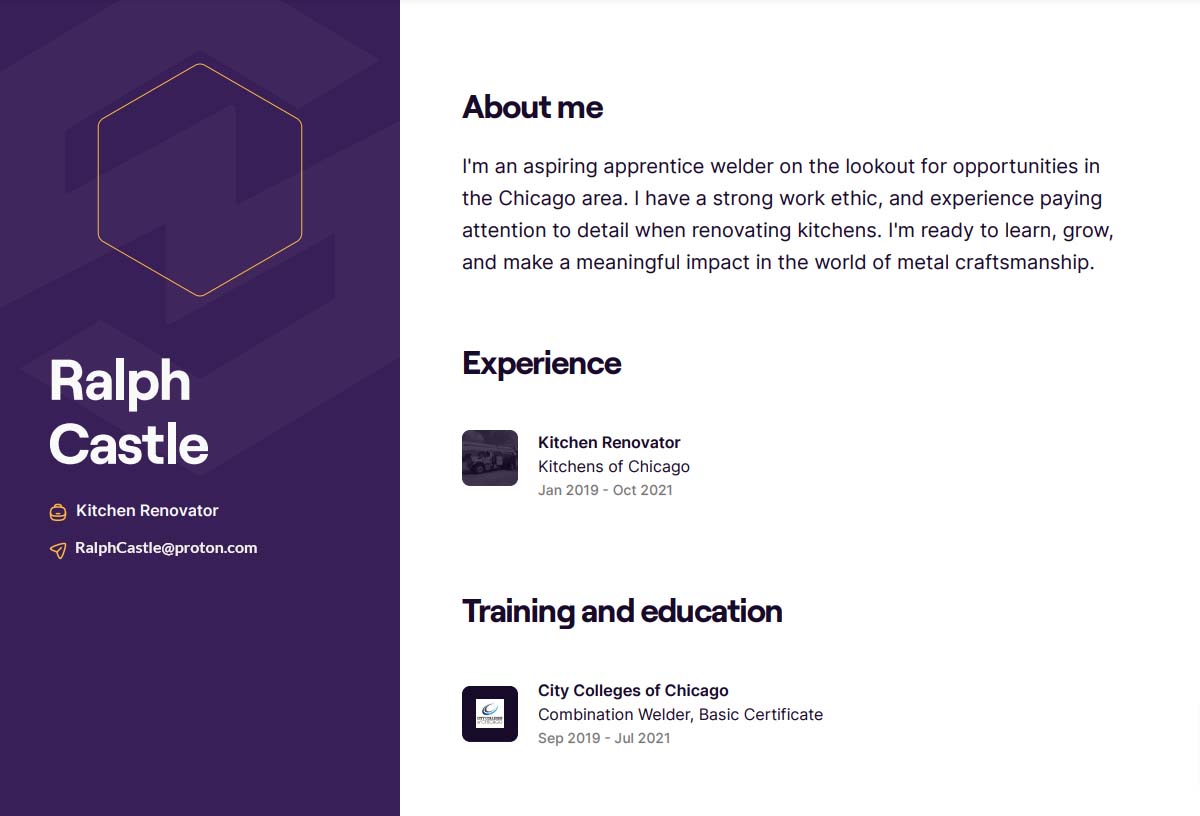

Apprentice welder resume sample

An apprentice welder's resume should highlight their training and certifications in various welding processes, as well as any relevant work experience and specialized projects they have completed.

The training and certifications section should detail the specific types of welding the apprentice is trained in, such as MIG, TIG, or stick welding. Work experience should showcase any relevant jobs or internships, and specialized projects should demonstrate the apprentice's ability to handle complex or unique welding tasks.

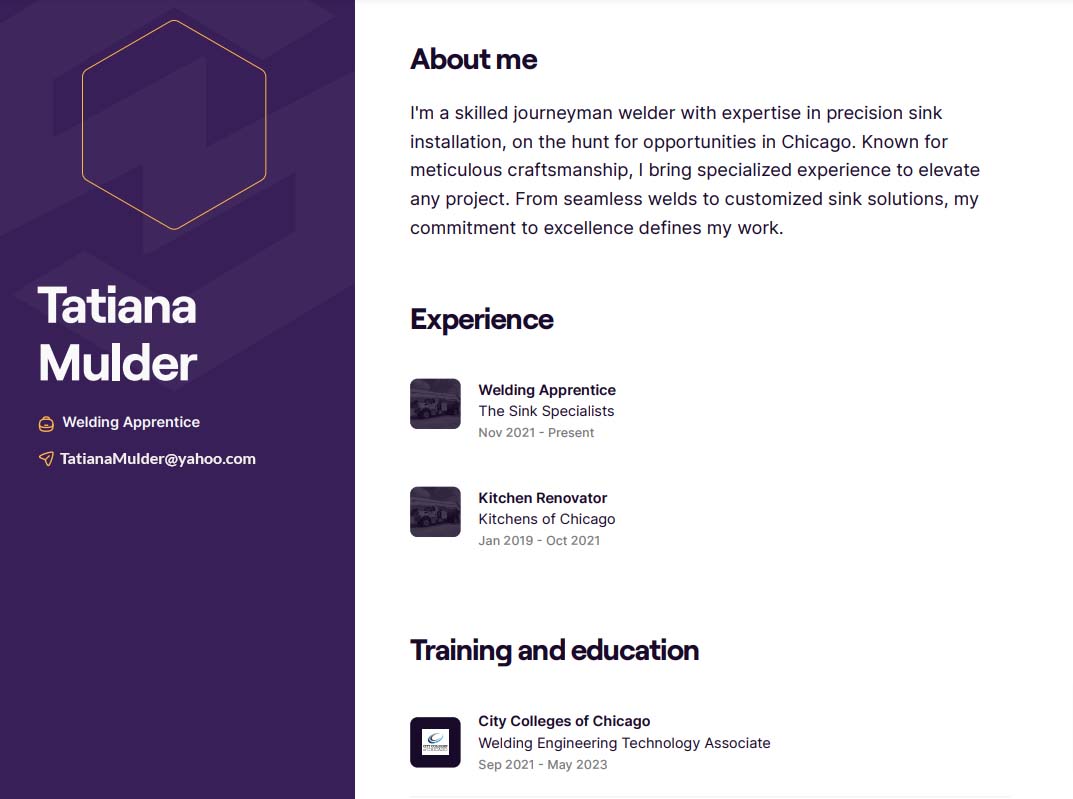

Journeyman welder resume sample

A journeyman welder's resume should prominently feature their certifications, work experience, specialized skills, and qualifications. Work experience should be detailed, including the types of projects worked on and any leadership or supervisory roles.

Including relevant qualifications such as OSHA training or experience with specific types of welding equipment is also crucial. Strong attention to detail and a focus on safety should be highlighted as well.

The resume should demonstrate the journeyman's expertise, reliability, and commitment to quality work.

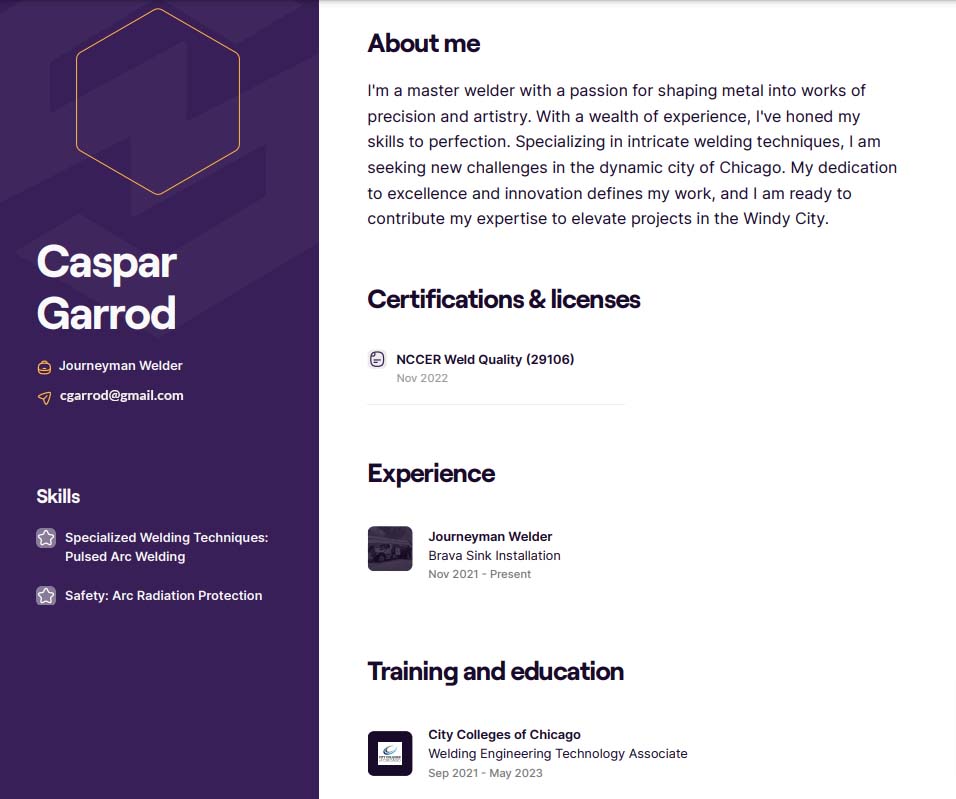

Master welder resume sample

A master welder's resume should showcase their extensive welding experience and specialized expertise. It must highlight their mastery of a wide variety of techniques, including metal inert gas (MIG), tungsten inert gas (TIG), and shielded metal arc welding (SMAW).

Experience in prototype manufacturing and the ability to work with a variety of welding tools and equipment should also be emphasized. The resume should demonstrate a strong track record of successful projects and a commitment to quality and precision in your work.

Master welders are expected to take on leadership or even education or training roles in workplaces where they may be the most experienced welder. Their confidence in the application of a variety of welding techniques should be apparent from their personal summary.

Which welding skills to include and where

In the welding industry, having a combination of technical job skills and soft skills is essential for long-term career success . Technical job skills, such as understanding different welding techniques, reading blueprints, and operating welding equipment, will help you meet an employer's specifications.

On the other hand, soft skills like communication, problem-solving, and teamwork are equally important for building strong professional relationships and advancing in the trade.

Technical welding skills

As a welder it's crucial to have the most relevant and up to date technical skills in order to excel in the industry.

For example, being proficient in utilizing Constant Current (CC) Welding Machines for various welding processes such as MIG, Stick, TIG, and Plasma Arc Welding is essential. These machines offer precision and control, allowing welders to produce high-quality welds in a variety of materials.

Having up-to-date skills can give you an advantage for premium contracts such such as automotive, aerospace, or pipeline welding. It may create opportunities to work with advanced welding technology, which in turn makes you a better candidate for future projects.

Soft skills for trade workers

Soft skills are essential for trade workers to excel in their role as part of a dynamic team. Handling pressure is important as trade jobs often come with demanding deadlines and unforeseen challenges.

Effective communication with team members and clients is crucial for a successful project, while strong time management ensures tasks are completed efficiently. Collaboration is key in trade industries, as workers often need to coordinate with others to achieve project goals.

To demonstrate these soft skills to employers, trade workers need to have a well optimized resume and the ability to answer questions and tell stories in a relaxed and professional manner when interviewed.

Tips and tricks for a great resume

Crafting a great resume is essential for standing out in the competitive job market. Whether you're a student looking for an apprenticeship or a skilled trade worker seeking new opportunities, having a polished and professional resume is the key to getting noticed by potential employers.

Here are some tips and tricks to help you create a standout resume that showcases your skills and experience:

Use career-focused keywords

When creating a resume, it's important to include career-focused keywords. These keywords are specific to your trade or industry and can help your resume stand out in the applicant tracking systems.

To start, carefully review the job description and identify the keywords that are relevant to the position. These may include specific skills, certifications, tools, or industry-related terminology. Incorporate these keywords throughout your resume, including in the skills section, work experience descriptions, and even in the summary or objective statement.

By strategically integrating career-focused keywords into your resume, you can increase its visibility and improve your chances of shortening your job search.

Use power words and verbs

Using power words and strong verbs in your resume is crucial for making a persuasive and engaging impression on potential employers.

These words can help to vividly and concisely describe your skills, experiences, and achievements, capturing the attention of hiring managers. They create a sense of clarity and impact, conveying your value in a way that stands out from other candidates.

Communicate your unique value

One of the most important resume tips is to clarify the unique value you can bring to potential employers. This will help potential employers see the value you can bring to their team.

To determine the unique value a company needs, research its hiring practices and current projects. If they produce specific metal products, you can identify the skills and safety procedures that are in high demand on their job sites. You can also find ways to draw parallels between your career goals and their company culture.

Ready to showcase your unique value to potential employers? Sign up for a free SkillHero account to access our free resume builder and our database of opportunities and training programs.

About the Author

We are the SkillHero skilled trades content development team.

- • Orchestrated the installation of new fabrication equipment at over 50 customer locations, enhancing operational efficiency by 30%.

- • Successfully repaired and maintained equipment in high-pressure situations, achieving a 98% on-time repair rate.

- • Pioneered a tooling improvement project, reducing equipment downtime by 25% through custom fabricated tools and solutions.

- • Led a team of technicians without supervision, delivering high-quality workmanship to meet customer specifications.

- • Generated comprehensive service reports after each project completion, ensuring transparency of service quality and leading to a 20% increase in customer satisfaction.

- • Directed overnight jobsite operations as part of a 24/7 emergency response team, maintaining exemplary service continuity.

- • Drove new equipment commissioning across various client sites, installing and calibrating machinery to exacting standards.

- • Facilitated workshops on effective utilization of spreadsheets and word processing programs for documenting repairs, improving team productivity by 15%.

- • Managed and maintained a valid Commercial Driver's License and DOT logs in accordance with regulations, ensuring legal compliance.

- • Authored and maintained detailed service manuals, contributing to an enhanced knowledge repository for the field team.

- • Executed critical welding and fabrication tasks, successfully completing projects 20% quicker than industry standards.

- • Improved structural integrity of machines through precise welding techniques, resulting in a 40% decrease in reported equipment failures.

- • Initiated a cross-training program for staff on PC operations, elevating the team's technical report generation skills.

- • Sourced and integrated high-quality component parts for complex equipment, enhancing longevity and performance.

- • Translated blueprint designs into tangible welded components, contributing significantly to the company's portfolio diversification.

5 Welder Resume Examples & Guide for 2024

Your welder resume must clearly highlight your technical proficiency. Specify the types of welding you have mastered, such as MIG, TIG, or stick welding. Ensure you include any certifications or qualifications, like AWS certifications, you've acquired. Demonstrating your commitment to safety and quality standards is essential.

All resume examples in this guide

Entry-Level Welding

Welder Fabricator

Structural Welder

Welder Engineer

Resume Guide

Resume Format Tips

Resume Experience

Skills on Resume

Education & Certifications

Resume Summary Tips

Additional Resume Sections

Key Takeaways

One key challenge you, as a welder, might encounter on your resume is showcasing the diversity of your welding techniques and project experience to potential employers. Our guide provides tailored strategies for effectively highlighting your specialized skills and the breadth of your work history, ensuring your resume stands out in a competitive job market.

- Format your welder resume to ensure that it balances professionalism with creativity, and follows the best practices.

- Match the welder job requirements by including industry keywords on your resume.

- Use various resume sections to showcase your skills and achievements to answer why you're the best candidate for the welder role.

Take inspiration from leading welder resume examples to learn how to tailor your experience.

- Plant Manager Resume Example

- Production Coordinator Resume Example

- Factory Manager Resume Example

- Machine Operator Resume Example

- Field Manager Resume Example

- Delivery Manager Resume Example

- Supply Chain Manager Resume Example

- Farm Manager Resume Example

- Forklift Operator Resume Example

- Parts Manager Resume Example

Enhancing your welder resume: format and layout tips

Four popular formatting rules (and an additional tip) are here to optimize your welder resume:

- Listing experience in reverse chronological order - start with your most recent job experiences. This layout helps recruiters see your career progression and emphasizes your most relevant roles.

- Including contact details in the header - make sure your contact information is easily accessible at the top of your resume. In the header, you might also include a professional photo.

- Aligning your expertise with the job requirements - this involves adding essential sections such as experience, skills, and education that match the job you're applying for.

- Curating your expertise on a single page - if your experience spans over a decade, a two-page resume is also acceptable.

Bonus tip: Ensure your welder resume is in PDF format when submitting. This format maintains the integrity of images, icons, and layout, making your resume easier to share.

Finally, concerning your resume format and the Applicant Tracker System (ATS):

- Use simple yet modern fonts like Rubik, Lato, Montserrat, etc.

- All serif and sans-serif fonts are friendly to ATS systems. Avoid script fonts that look like handwriting, however.

- Fonts such as Ariel and Times New Roman are suitable, though commonly used.

- Both single and double-column resumes can perform well with the ATS.

Upload & Check Your Resume

Drop your resume here or choose a file . PDF & DOCX only. Max 2MB file size.

Always remember that your welder certifications can be quantified across different resume sections, like your experience, summary, or objective. For example, you could include concise details within the expertise bullets of how the specific certificate has improved your on-the-job performance.

Welder resume sections to answer recruiters' checklists:

- Header to help recruiters quickly allocate your contact details and have a glimpse over your most recent portfolio of work

- Summary or objective to provide an overview of your career highlights, dreams, and goals

- Experience to align with job requirements and showcase your measurable impact and accomplishments

- Skills section/-s to pinpoint your full breadth of expertise and talents as a candidate for the Welder role

- Education and certifications sections to potentially fill in any gaps in your experience and show your commitment to the industry

What recruiters want to see on your resume:

- Certifications in welding (e.g., AWS Certified Welder, ASME certifications)

- Hands-on experience with specific welding techniques (e.g., MIG, TIG, Stick, Flux-Cored)

- Knowledge of safety protocols and adherence to OSHA regulations

- Familiarity with welding equipment maintenance and troubleshooting

- Ability to read and interpret technical documents, such as blueprints and weld symbols

Creating your welder resume experience to catch recruiters' attention

Remember that for the welder role, hiring managers are looking to see how your expertise aligns with their requirements. Here's where your resume experience section can help out. Make sure you:

- Include mainly roles that are relevant to the welder job you're applying for;

- Don't go too far back in your experience - recruiters will only care what you did a decade ago if it's really important for the welder role;

- Each bullet you include should say what you did, followed by the skills you used and the actual end result of your efforts;

- Quantify each of your achievements with numbers and possibly the overall effect it had on the organization;

- Highlight transferrable skills - or personal skills you've attained thanks to past jobs - that could be applicable within your potential workplace. This would showcase your unique value as a professional.

Formatting the experience section of your resume doesn't have to be an over-the-top deep dive into your whole career. Follow the welder resume examples below to see how industry-leading professionals are presenting their experience:

- Served as a lead welder on construction of a new wing for a commercial building, supervising a team of 5 and improving overall project efficiency by 20%.

- Mastered advanced MIG and TIG welding techniques to produce high-quality welds on a variety of metals, including stainless steel and aluminum, reducing repair work by 15%.

- Collaborated with engineering team to interpret blueprints and layout plans, which led to a decrease in construction discrepancies by approximately 10%.

- Implemented a rigorous safety protocol for the welding team, resulting in 2 years without incident and recognition from the company for outstanding safety performance.

- Conducted in-depth material inspections to ensure a 100% compliance rate with industry standards, directly impacting project integrity and lifespan.

- Designed a time-saving welding fixture that improved operational efficiency by 25% and was later adopted company-wide.

- Demonstrated expert proficiency in using SMAW and FCAW welding processes on heavy industrial projects, which notably increased project completion speed by 30%.

- Participated in the successful completion of a crucial pipeline project that supplied a major city with water, ensuring zero leaks upon first testing.

- Initiated a peer-review process for welds which decreased error rates by 20% and enhanced overall quality of work.

- Spearheaded the development and implementation of an automated welding system, which amplified productivity by 35%.

- Responsible for performing critical welds on aerospace components, maintaining a 99% acceptance rate by QA standards.

- Engaged in continuous professional development to remain abreast of the latest welding technologies, contributing to the company's innovation in welding processes.

- Achieved a weld failure rate of less than 1% on high-pressure vessels, which was well below the industry standard and led to an award for exceptional craftsmanship.

- Efficiently executed over 500 critical welds for offshore oil rigs, each requiring meticulous precision to ensure the safety and functionality of the rigs.

- Developed a training program for new welders that improved the onboarding process and increased the skill level of the welding team by 40%.

- Optimized welding techniques to help complete a large-scale bridge reconstruction project 2 months ahead of schedule, earning a company bonus for the team.

- Orchestrated a shift rotation system that maximized utilization of welding equipment, leading to a 10% reduction in operational costs due to decreased downtime.

- Contributed to the development of a proprietary welding consumable mixture that increased the strength of welds by 20%, enhancing the structural integrity of completed work.

- Led a team that fabricated and installed custom stainless steel equipment for the food processing industry, adhering to USDA guidelines and exceeding customer satisfaction standards.

- Achieved a perfect record of weld integrity in audited projects, surpassing industry expectations and providing lasting value to the company portfolio.

- Generated a 30% increase in productivity by introducing a lean welding workflow, which streamlined the project execution process.

- Successfully completed over 200 marine welding assignments, contributing to the maintenance and repair of vessels which enhanced the fleet's uptime by 50%.

- Pioneered the use of an advanced hyperbaric welding technique, allowing the company to take on complex underwater repair jobs that diversified revenue streams.

- Mentored 10 apprentices in high-stakes welding scenarios, equipping them with crucial skills that improved their precision and efficiency by 35% on average.

Quantifying impact on your resume

- Include the number of welding projects completed to demonstrate experience and productivity.

- List the types and thicknesses of metals you have worked with to showcase versatility.

- Mention specific metrics improved through your welding work, such as reducing material waste by a certain percentage.

- Highlight any increase in efficiency, such as decreasing project completion time, with quantifiable figures.

- Detail the size of the teams you've led or collaborated with on welding projects to emphasize team and leadership skills.

- Provide figures on how you helped cut costs for projects by implementing new welding techniques or technology.

- Cite safety records or reductions in accidents/incidents due to your attention to safety protocols and training.

- Quantify the scale of the welding work by specifying the weight or length of materials you've welded in past projects.

Action verbs for your welder resume

Guide for welder professionals kicking off their career

Who says you can't get that welder job, even though you may not have that much or any experience? Hiring managers have a tendency to hire the out-of-the-blue candidate if they see role alignment. You can show them why you're the best candidate out there by:

- Selecting the functional skill-based or hybrid formats to spotlight your unique value as a professional

- Tailoring your welder resume to always include the most important requirements, found towards the top of the job ad

- Substituting the lack of experience with other relevant sections like achievements, projects, and research

- Pinpoint both achievements and how you see yourself within this specific role in the welder resume objective.

Recommended reads:

- When You Should (And Not) Add Dean's List On Your Resume

- How to List a Major & Minor on Your Resume (with Examples)

Bold the names of educational institutions and certifying bodies for emphasis.

Bringing your welder hard skills and soft skills to the forefront of recruiters' attention

Hard skills are used to define the technological (and software) capacities you have in the industry. Technical skills are easily defined via your certification and expertise.

Soft skills have more to do with your at-work personality and how you prosper within new environments. People skills can be obtained thanks to your whole life experience and are thus a bit more difficult to define.

Why do recruiters care about both types of skills?

Hard skills have more to do with job alignment and the time your new potential employers would have to invest in training you.

Soft skills hint at how well you'd adapt to your new environment, company culture, and task organization.

Fine-tune your resume to reflect on your skills capacities and talents:

- Avoid listing basic requirements (e.g. "Excel"), instead substitute with the specifics of the technology (e.g. "Excel Macros").

- Feature your workplace values and ethics as soft skills to hint at what matters most to you in a new environment.

- Build a separate skills section for your language capabilities, only if it makes sense to the role you're applying for.

- The best way to balance welder hard and soft skills is by building a strengths or achievements section, where you define your outcomes via both types of skills.

There are plenty of skills that could make the cut on your resume.

That's why we've compiled for you some of the most wanted skills by recruiters, so make sure to include the technologies and soft skills that make the most sense to you (and the company you're applying for):

Top skills for your welder resume:

Gas metal arc welding (GMAW/MIG)

Gas tungsten arc welding (GTAW/TIG)

Shielded metal arc welding (SMAW)

Flux-cored arc welding (FCAW)

Soldering and brazing

Reading blueprints and schematics

Metal fabrication

Welding equipment maintenance

Thermal cutting (plasma, torch, laser)

Understanding of welding codes and standards

Attention to detail

Manual dexterity

Physical strength

Spatial awareness

Problem-solving

Communication

Time management

Adaptability

Safety consciousness

Mention specific courses or projects that are pertinent to the job you're applying for.

Education section and most popular welder certifications for your resume

Your resume education section is crucial. It can indicate a range of skills and experiences pertinent to the position.

- Mention only post-secondary qualifications, noting the institution and duration.

- If you're still studying, highlight your anticipated graduation date.

- Omit qualifications not pertinent to the role or sector.

- If it provides a chance to emphasize your accomplishments, describe your educational background, especially in a research-intensive setting.

Recruiters value welder candidates who have invested their personal time into their professional growth. That's why you should include both your relevant education and certification . Not only will this help you stand out amongst candidates, but showcase your dedication to the field. On your welder resume, ensure you've:

- Curated degrees and certificates that are relevant to the role

- Shown the institution you've obtained them from - for credibility

- Include the start and end dates (or if your education/certification is pending) to potentially fill in your experience gaps

- If applicable, include a couple of job advert keywords (skills or technologies) as part of the certification or degree description

If you decide to list miscellaneous certificates (that are irrelevant to the role), do so closer to the bottom of your resume. In that way, they'd come across as part of your personal interests, instead of experience. The team at Enhancv has created for you a list of the most popular welder certificates - to help you update your resume quicker:

The top 5 certifications for your welder resume:

- Certified Welder (CW) - American Welding Society (AWS)

- Certified Welding Inspector (CWI) - American Welding Society (AWS)

- Certified Welding Educator (CWE) - American Welding Society (AWS)

- Certified Welding Engineer (CWE) - American Welding Society (AWS)

- Certified Welding Supervisor (CWS) - American Welding Society (AWS)

Highlight any significant extracurricular activities that demonstrate valuable skills or leadership.

- How to List GPA on Your Resume

- How To Include Your Relevant Coursework On A Resume

Welder resume summary or objective? The best choice is based on your experience

If you're wondering about the relevancy of the resume summary or the resume objective to your Welder application - here's the truth.

The summary and objective provide recruiters with your expertise and accomplishments at a glance, within an up-to-five-sentence structure.

The difference is that the:

- Resume objective is also more focused on emphasizing your career goals. The objective is the perfect fit for (potentially more junior) candidates who'd like to balance their relevant experience with their career goals.

- Resume summary can provide you with space to also detail the unique value of what it's like to work with you. Welder candidates who have many noteworthy accomplishments start from the get-go with their summary.

Ensure that either type of resume introduction presents your Welder expertise in the best light and aligns it with the job advert.

The more details you can provide with numbers, the more compelling your resume summary or objective will be.

Real-world Welder candidates follow these frameworks in writing their resume summaries and objectives.

The end results are usually as such:

Resume summaries for a welder job

- Seasoned welder with over 15 years of dedicated experience, offering a solid track record in MIG, TIG, and stick welding. Responsible for implementing a new welding process that increased productivity by 30% at XYZ Corporation. Holds credentials from the American Welding Society and thrives in high-pressure, precision-demanding work environments.

- Accomplished mechanical engineer transitioning to welding with 10 years in the automotive industry, bringing expertise in materials science and a passion for metal fabrication. Completed a professional welding certification to leverage mechanical design and manufacturing knowledge into practical welding applications for robust and innovative metalworking solutions.

- Dynamic ex-military professional with expert training in metallic repair and a 20-year tenure; transitioning into civilian welding operations. Recently graduated from a top-rated welding school with hands-on experience in SMAW and GMAW techniques, eager to apply disciplined work ethic and attention to detail to advance in the metalwork industry.

- Former construction project manager with a decade of experience leading infrastructure projects, now pursuing a career as a professional welder. Completed intensive welding training and certified in advanced welding techniques, demonstrating a unique blend of leadership skills and technical prowess to enhance quality and efficiency of welding operations.

- Enthusiastic newcomer to the welding industry, aiming to leverage a background in automotive mechanics and recent training in welding from the Lincoln Tech Institute. Eager to learn from seasoned professionals while contributing to high-stakes projects that demand precision and skill, and to grow as a respected welder in the field.

- Recent vocational graduate seeking to begin a career in welding, with fresh knowledge of the latest welding technologies, including virtual reality simulation training. Aspires to bring a strong work ethic and dedicated learning attitude to a team focused on quality craftsmanship, and to evolve through practical experience into a skilled and reliable welding professional.

More sections to ensure your welder resume stands out

If you're looking for additional ways to ensure your welder application gets noticed, then invest in supplementing your resume with extra sections, like:

- Publications;

These supplementary resume sections show your technical aptitude (with particular technologies and software) and your people skills (gained even outside of work).

Key takeaways

- Impactful welder resumes have an easy-to-read format that tells your career narrative with highlights;

- Select a resume summary or objective, depending on what sort of impression you'd like to leave and if your accomplishments are relevant to the job;

- If you don't happen to have much industry expertise, curate additional gigs you've had, like contracts and internships, to answer how your experience aligns with the welder job;

- Be specific about the hard and soft skills you list on your resume to define your niche expertise and outcomes of using those particular skills;

- Always tailor your resume for each welder application to ensure you meet all job requirements.

Looking to build your own Welder resume?

- Resume Examples

Can I Send A Resume Instead Of A CV

Why does my resume look different when i upload it, 30 resume tips and advice for 2024 [with expert insights], do i need to sign a cover letter submitted electronically, how to answer the "tell me about yourself" interview question, how i got an internship at tesla.

- Create Resume

- Terms of Service

- Privacy Policy

- Cookie Preferences

- Resume Templates

- AI Resume Builder

- Resume Summary Generator

- Resume Formats

- Resume Checker

- Resume Skills

- How to Write a Resume

- Modern Resume Templates

- Simple Resume Templates

- Cover Letter Builder

- Cover Letter Examples

- Cover Letter Templates

- Cover Letter Formats

- How to Write a Cover Letter

- Resume Guides

- Cover Letter Guides

- Job Interview Guides

- Job Interview Questions

- Career Resources

- Meet our customers

- Career resources

- English (UK)

- French (FR)

- German (DE)

- Spanish (ES)

- Swedish (SE)

© 2024 . All rights reserved.

Made with love by people who care.

Privacy preference center

We care about your privacy

When you visit our website, we will use cookies to make sure you enjoy your stay. We respect your privacy and we’ll never share your resumes and cover letters with recruiters or job sites. On the other hand, we’re using several third party tools to help us run our website with all its functionality.

But what exactly are cookies? Cookies are small bits of information which get stored on your computer. This information usually isn’t enough to directly identify you, but it allows us to deliver a page tailored to your particular needs and preferences.

Because we really care about your right to privacy, we give you a lot of control over which cookies we use in your sessions. Click on the different category headings on the left to find out more, and change our default settings.

However, remember that blocking some types of cookies may impact your experience of our website. Finally, note that we’ll need to use a cookie to remember your cookie preferences.

Without these cookies our website wouldn’t function and they cannot be switched off. We need them to provide services that you’ve asked for.

Want an example? We use these cookies when you sign in to Kickresume. We also use them to remember things you’ve already done, like text you’ve entered into a registration form so it’ll be there when you go back to the page in the same session.

Thanks to these cookies, we can count visits and traffic sources to our pages. This allows us to measure and improve the performance of our website and provide you with content you’ll find interesting.

Performance cookies let us see which pages are the most and least popular, and how you and other visitors move around the site.

All information these cookies collect is aggregated (it’s a statistic) and therefore completely anonymous. If you don’t let us use these cookies, you’ll leave us in the dark a bit, as we won’t be able to give you the content you may like.

We use these cookies to uniquely identify your browser and internet device. Thanks to them, we and our partners can build a profile of your interests, and target you with discounts to our service and specialized content.

On the other hand, these cookies allow some companies target you with advertising on other sites. This is to provide you with advertising that you might find interesting, rather than with a series of irrelevant ads you don’t care about.

Welder Resume Examples & Writing Guide for 2024

5 steps for writing an effective welder resume

Welders are essential for the creation and repair of metal goods. Without experienced and professional welders around, our cities and towns would lack critical components to their infrastructure and industrial systems. As a result, employers seek out motivated welders with a high level of adaptability and willingness to learn.

In this guide, we will cover everything you need to know about writing a resume as a welder. Keep reading to learn how to:

- Select a reverse-chronological format to showcase your experience

- Create a resume summary that highlights your specializations and accomplishments

- Include soft skills along with hard skills on your welder resume

- Write a welder work experience section tailored for the job

- List your education and certifications correctly as a welder

Still looking for a job? These 100+ resources will tell you everything you need to get hired fast.

1. Select a reverse-chronological format to showcase your experience

As a welder, you want to emphasize your formal work experience whenever possible on your resume.

To do this, your best formatting option is the reverse-chronological resume . This resume format focuses almost entirely on work experience, making it the largest and most prominent section on the document. Within this section, you will detail your most recent job first and work backward from there.

Reverse-chronological resumes work wonders for applicants with enough experience to fill them out fully – but what about those applicants with limited experience?

There are two main alternatives to the RC resume:

- Functional Resume: The functional resume focuses on education and skills instead of experience. This format is well-suited for applicants who have recently graduated high school or college and who do not yet have an extensive work history.

- Hybrid Resume: The hybrid resume combines elements of both the functional and reverse-chronological formats, placing more equal emphasis amongst all sections. This format works well for candidates with limited work experience, those who switching careers, or those who have large gaps in their employment history.

Choose your preferred template and make your resume shine.

2. Create a welder resume summary that highlights your specializations and accomplishments

A resume summary is a brief statement that starts off your resume. This summary is often used as an introduction of the applicant to employers, helping to establish them as qualified and driven professionals.

For welders, the resume summary offers a great opportunity to highlight your best strengths, specializations, and any key accomplishments from your time in previous positions.

Below we have provided an example of a weak welder resume summary, followed by a corrected example and explanation.

Incorrect welder professional summary example

Experienced Welder with over 10 years working in the field. Well-versed in a variety of welding techniques and working with many different types of materials. Recipient of a county-wide customer service award recognizing exemplary service.

Why is this Incorrect?

Whenever you write a resume summary, you should aim to be as specific as possible. Remember – this summary will help to introduce you, as an applicant, to the employer. You want to include specific details that help your resume summary become more engaging and interesting, compelling employers to read onwards.

Corrected welder professional summary example

Motivated Welder with 10+ years of experience utilizing a full range of welding techniques. Specialized in the use of steel, copper, cast iron, and aluminum. Recipient of the Most Reliable Welder of 2020 award, given by the Buncombe County Chamber of Commerce.

Why is this Correct?

In this corrected example, the applicant offers a much higher level of detail, including the exact name of the award they earned and what types of metals they are specialized in working with. This makes the summary much stronger, with more active language and intention bolstering the strength of the words.

Find out your resume score!

3. Include soft skills along with hard skills on your welder resume

When working as a welder, it can be easy to focus too much on your technical abilities and neglect your interpersonal abilities as a result.

On a resume, employers expect to see both hard and soft skills . Hard skills refer to the technical abilities a person possesses that must be earned through education and training. Soft skills , by comparison, are the interpersonal abilities that define how easy and professional a person is to work with. While soft skills can be learned and improved, they also tend to be inherent qualities of a person as well.

To help you brainstorm ideas for both hard and soft skills to include on your resume, here are 10 examples of both to get you started:

The best hard skills to put on your welder resume

- Metal fabrication

- Reviewing blueprints

- Calculating dimensions

- Project planning and panagement

- Manufacturing metal structures, tools, and equipment

- Specializations in specific saterials (steel, copper, etc.)

- Basic mathematical skills

- 2-D and 3-D diagrams

- Identifying joints

- Cutting and trimming metal

Effective welder soft skills for your CV

- Exceptional attention to detail

- Verbal and non-verbal communication

- Teamwork and collaboration

- Spatial reasoning

- Hand-eye coordination

- Organization

- Reliability

- Time management

- Independent working

- Visualization

4. Write a welder work experience section tailored for the job

Your work experience section should not only showcase your key responsibilities and accomplishments from a previous job. It should also help reflect the desired skills and experience the employer is asking for, establishing you as a highly qualified candidate for the position.

As you write your work experience section, consider what specific details you can include that make you a more competitive candidate, such as statistics or improvements to a company that you directly helped achieve.

Here is an example of a work experience entry from a welder resume

Beacon Welding Co., Salem, MA Journeyman Welder June 2017 to November 2019

- Accurately interpreted diagrams, sketches, and blueprints to determine and obtain the best materials and design plans for a given job.

- Implemented new onsite safety standards that helped to reduce at-work injuries by 15%.

- Operated, monitored, and maintained a variety of welding machines and metalworking equipment.

5. List your education and certifications correctly as a welder

There is no singular pathway to becoming a welder. For applicants who are recent graduates of high school, there may have been in-school opportunities to learn the craft of welding and become certified.

For other older applicants, earning a career in welding can be achieved via vocational school, community college, or certified training programs.

No matter what your level of education is , make sure to include the following details on your resume:

- Your highest level of education (high school diploma, GED, Bachelor’s Degree, etc.)

- The school or university you attended

- Your date of graduation

As for certifications, you should always include at minimum the formal name of the certificate earned and the certifying institution. If the certification has an expiration date, include this information as well.

Here is an example of a well-crafted education section on a welder resume

Central Carolina Community College Associates Degree in Welding Technology

- Graduated: 2018

Certifications

- Safety in Welding Certificate — Central Carolina Community College

- Certified Welding Fabricator — American Welding Society

Nikoleta Kuhejda

A journalist by trade, a writer by fate. Nikoleta went from writing for media outlets to exploring the world of content creation with Kickresume and helping people get closer to the job of their dreams. Her insights and career guides have been published by The Female Lead , College Recruiter , and ISIC, among others. When she’s not writing or (enthusiastically) pestering people with questions, you can find her traveling or sipping on a cup of coffee.

All manufacturing resume examples

- Assembly Line Worker

- Hair Stylist

- Manufacturing Engineer

- Metal Worker

All welder resume examples

Related welder cover letter examples.

Resume guides

How to write a professional resume summary [+examples], how to put your education on a resume [+examples], how to describe your work experience on a resume [+examples], let your resume do the work..

Join 5,000,000 job seekers worldwide and get hired faster with your best resume yet.

Resume Builder

- Resume Experts

- Search Jobs

- Search for Talent

- Employer Branding

- Outplacement

- Resume Samples

- Building and Construction

Welder Resume Samples

The guide to resume tailoring.

Guide the recruiter to the conclusion that you are the best candidate for the welder job. It’s actually very simple. Tailor your resume by picking relevant responsibilities from the examples below and then add your accomplishments. This way, you can position yourself in the best way to get hired.

Craft your perfect resume by picking job responsibilities written by professional recruiters

Pick from the thousands of curated job responsibilities used by the leading companies, tailor your resume & cover letter with wording that best fits for each job you apply.

Create a Resume in Minutes with Professional Resume Templates

- Maintain a safe, clean and orderly work environment by following all safety protocols and performing routine housekeeping and workplace organization

- Assist in the development of work instructions

- Performs all work in accordance with established safety procedures, documenting parts usage, and accounting for repair times

- Perform all work in accordance with established safety procedures

- Read and interpret instructions and documentation and plans work activities. Moves materials and equipment to work locations and sets up work site

- Observes all company policies, works shift work, and is consistently at work on time

- Perform work in a professional and safe manner, report unsafe work practices

- Uses various tools provided in the work area to perform welding duties to perform welding duties including but not limited to

- Make a continuous effort to improve operations, decrease turnaround times, streamline work processes, and work cooperatively and jointly

- Responsible for refusing unsafe work and for carrying out all work in accordance with the established HSES Safety Standards and Work Practices

- Make continuing improvements and work within LEAN guidelines for continuous process improvement

- Maintains a clean, safe work area in compliance with Corporate / OSHA Standards, and performs all work in accordance with established safety procedures

- Performing any combination of duties to assist workers in welding, brazing, and thermal and arc cutting activities

- Performs all work in accordance with established safety procedures

- Basic knowledge of the ability to use a variety of basic hand tools (e.g. wrenches, hammers, screwdrivers, scrappers, box cutters)

- Strong working knowledge of job site safety as well as ability to complete a company specific safety orientation

- Provide evidence of the ability to read and interpret engineering drawings, basic knowledge of GD&T and welding symbols

- General knowledge and ability to perform basic construction and utility tasks such as equipment operation, pipefitting, etc

- Ability to learn product software quickly and operate software and CNC machinery proficiently

- Able to define, evaluate and discuss quality workmanship related to welding

- Knowledge of codes and industry standards applicable to work performed

- Demonstrate good decision making skills and the ability to prioritize work

- Knowledgeable of welding techniques and manufacturing processes through prior experience or training programs

- Ability to analyst and update reports, forms, records and comparable methods of data collection tools

15 Welder resume templates

Read our complete resume writing guides

How to tailor your resume, how to make a resume, how to mention achievements, work experience in resume, 50+ skills to put on a resume, how and why put hobbies, top 22 fonts for your resume, 50 best resume tips, 200+ action words to use, internship resume, killer resume summary, write a resume objective, what to put on a resume, how long should a resume be, the best resume format, how to list education, cv vs. resume: the difference, include contact information, resume format pdf vs word, how to write a student resume, welder resume examples & samples.

- Reports to Shop Manager

- Operate independently

- Operate welding, burning and other shop equipment,

- Responsible for their portion of required paperwork related to the implementation and completion of a job

- Responsible for assisting Shop Manager, address all issues that arise in pipe & fabrication shop

- Able to work alone or with minimal supervision

- Must be able to read blue prints, and have essential math skills

- Responsible for maintaining an inventory of welding materials, tools and supplies necessary to complete welding and burning tasks related to each job

- Responsible for proper fit up and welding of materials

- Performs other duties pertaining to the completion of the job at the direction of Shop Manager or other supervisor

- Is required to ensure that they maintain safe work practices as required by company, policies and guidelines

- Able to give and understand hand crane signals

- Ensuring the job is complete, shop is clean and organized

- Maintaining assigned equipment including repair, maintenance, cleaning, organize and stock for each job

- High School Diploma or Equivalent

- Valid welding certificate by an accredited testing facility

- Comprehend and communicate complex oral and written instructions

- Connect regular valves and bases to oxygen and fuel gas cylinders and welding torches

- Hold torches at proper angles to joints to be welded

- Apply filler rods to molten area to form welds

- Weld, braze, and cut nitronics, aluminum, titanium, stainless steel, and SAE 4130 steels according to blueprint specifications and operation sheet instructions

- Examine welds for bead size, penetration, and other specifications

- Grind off excess slag or spatter

- Ability to locate, identify and use proper fixtures and tooling to perform weld operations

- Repair non-standard flaws with limited or no assistance

- Use drawings, gauges, to ensure conformance to safety and quality specifications

- Ability to perform operations with close tolerance and finish requirements on standardized parts

- Conduct pre and post inspection on all welded parts

- Assist in the development of new fixtures

- Plan and make new or difficult setups with welding machine

- Can effectively perform stainless steel, hardfacing, etc welding

- Can effectively collaborate with Section Manager and Manufacturing Engineer

- Assist other team members with technical issues and/or production problems

- Efficiently perform all process as assigned

- Perform general maintenance as required

- Compliance with 5S programme and other business improvement initiatives

- Attend planned training

- Train other employees as and when required

- Any other appropriate duties

- Two years or more experience in a welding environment

- Ability to perform welding activities with MIG/MAG (GMAW) and SMAW technology

- Ability to understand drawings

- Ability to manufacture quality products

- Problem solving and Change Management

- Strong commitment to Safety

- Physically able to fulfill the job requirements

- Welder qualification record

- Previous experience working in a lean environment

- Attention to detail to meet quality standards

- Welding together fabricated piece parts by using semi-automatic MIG welder

- 1 to 2 years of welding experience

- Experience in vertical or overhead welding

- Welding certification or associates degree

- Reviews work order packet to determine the location of piece parts, fixture, and accuracy of the Bill of Material

- Visually checks piece parts for quality and verifies that piece part quantity matches the blueprint. Reports any discrepancies to the Supervisor

- Follows set-up guidelines and procedures to assemble and tack weld unit by using various tools such as drop chains, chain hoist, metal shims, wedges, lifting lugs, "C" clamps, bar clamps, com-a-long, cutting torch, grinder, tape measure, fixtures, and weld gauges

- Sets the weld machine to correct setting for the weld application

- Welds unit to print specifications following guidelines and procedure to control warpage on all common product built throughout the Weld Department to include: U-Blades (4-10,000 lb.), Hydraulic Angle Blades, Buckets (4-8000 lb.), Excavator Buckets, Lift Groups, and Quick Couplers

- Uses air arc and grinder to remove or repair unacceptable welds in order to meet quality guidelines

- Inspects welds and checks critical measurements upon completion to ensure they meet specifications and criteria

- Experience welding on 1/2" thick steel

- Experience with spray arc welding

- Manual MIG Welding

- Ability to clear common robotic welding system faults in all qualified work stations

- Must be able to inspect own work including quality checks utilizing weld and attribute gages and other measuring tools

- Mechanical job duties may include the following

- Complete routine maintenance (wire change, tip/nozzle change) in all qualified work stations

- Follows documented procedures, standard work, routings, and blueprints to perform safe and defect free operations

- Contributing team member

- Ability to sit or stand for prolonged periods

- Ability to perform repetitive operations

- Ability to lift up to 35 lbs

- Completion of Welder 1 observation period at valued performance level

- Must be able to demonstrate proficiency with carbon air arc weld removal

- Must be able to pass the following AWS D1.1welder qualification tests

- Verify accuracy of the Bill of Material

- Verifies that piece part quantity matches the blueprint

- Reports discrepancies

- Welding Certification or 5 years of Welding experience

- Knowledge of welding applications

- Knowledge of U-Blades (4-10,000 lb.), Hydraulic Angle Blades, Buckets (4-8000 lb.), Excavator Buckets, Lift Groups, and Quick Couplers

- Certified Welder

- Clean parts to existing weld specs

- Placement of parts in fixture in proper sequence

- Ensure dimensional accuracy before and after tack welding

- Tack weld parts in proper sequence using WPM or SW when it exists

- Remove weldment safely from fixture and move to work table/horses/positioner

- Set welder to prescribed settings

- Ability to weld item completely; ensure all welds and surfaces meet Cat quality standards per

- 1E specifications

- Operates sanders, wire wheels and other tools used to clean weldments for paint readiness

- Reports all discrepancies to Team Lead

- Does required daily inspections of lifting devices, tools, etc. to ensure safe work environment

- Uses all PPE required for work classification

- Ability to troubleshoot fit up issues, complex welding and/or welder malfunctions

- Works well with minimal direction, can locate and interpret relevant Standard Work and

- Ability to skillfully perform all welding processes ie SAW, GMAW and CAC

- Successful completion of the CPS Weld Instruction Course

- Welding certification preferred and 5 years experience or 4+ years weld fabrication experience

- Vocational weld training and production manufacturing weld experience

- Ability to consistently achieve all PQVC requirements

- Ability to troubleshoot fit up issues, intermediate welding and/or welder malfunctions

- Welding certification preferred and 3+ years of weld fabrication experience or equivalent

- Use blueprints, gauges, torque measuring devices and/or other equipment to ensure conformance to quality specifications

- Ability to set-up, adjust and perform operations with close tolerance and finish requirements on standardized parts