- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- AI Essentials for Business

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

Root Cause Analysis: What It Is & How to Perform One

- 07 Mar 2023

The problems that affect a company’s success don’t always result from not understanding how to solve them. In many cases, their root causes aren’t easily identified. That’s why root cause analysis is vital to organizational leadership .

According to research described in the Harvard Business Review , 85 percent of executives believe their organizations are bad at diagnosing problems, and 87 percent think that flaw carries significant costs. As a result, more businesses seek organizational leaders who avoid costly mistakes.

If you’re a leader who wants to problem-solve effectively, here’s an overview of root cause analysis and why it’s important in organizational leadership.

Access your free e-book today.

What Is Root Cause Analysis?

According to the online course Organizational Leadership —taught by Harvard Business School professors Joshua Margolis and Anthony Mayo— root cause analysis is the process of articulating problems’ causes to suggest specific solutions.

“Leaders must perform as beacons,” Margolis says in the course. “Namely, scanning and analyzing the landscape around the organization and identifying current and emerging trends, pressures, threats, and opportunities.”

By working with others to understand a problem’s root cause, you can generate a solution. If you’re interested in performing a root cause analysis for your organization, here are eight steps you must take.

8 Essential Steps of an Organizational Root Cause Analysis

1. identify performance or opportunity gaps.

The first step in a root cause analysis is identifying the most important performance or opportunity gaps facing your team, department, or organization. Performance gaps are the ways in which your organization falls short or fails to deliver on its capabilities; opportunity gaps reflect something new or innovative it can do to create value.

Finding those gaps requires leveraging the “leader as beacon” form of leadership.

“Leaders are called upon to illuminate what's going on outside and around the organization,” Margolis says in Organizational Leadership , “identifying both challenges and opportunities and how they inform the organization's future direction.”

Without those insights, you can’t reap the benefits an effective root cause analysis can produce because external forces—including industry trends, competitors, and the economy—can affect your company’s long-term success.

2. Create an Organizational Challenge Statement

The next step is writing an organizational challenge statement explaining what the gap is and why it’s important. The statement should be three to four sentences and encapsulate the challenge’s essence.

It’s crucial to explain where your organization falls short, what problems that poses, and why it matters. Describe the gap and why you must urgently address it.

A critical responsibility is deciding which gap requires the most attention, then focusing your analysis on it. Concentrating on too many problems at once can dilute positive results.

To prioritize issues, consider which are the most time-sensitive and mission-critical, followed by which can make stakeholders happy.

3. Analyze Findings with Colleagues

It's essential to work with colleagues to gain different perspectives on a problem and its root causes. This involves understanding the problem, gathering information, and developing a comprehensive analysis.

While this can be challenging when you’re a new organizational leader, using the double helix of leadership —the coevolutionary process of executing organizational leadership's responsibilities while developing the capabilities to perform them—can help foster collaboration.

Research shows diverse ideas improve high-level decision-making, which is why you should connect with colleagues with different opinions and expertise to enhance your root cause analysis’s outcome.

4. Formulate Value-Creating Activities

Next, determine what your company must do to address your organizational challenge statement. Establish three to five value-creating activities for your team, department, or organization to close the performance or opportunity gap you’ve identified.

This requires communicating organizational direction —a clear and compelling path forward that ensures stakeholders know and work toward the same goal.

“Setting direction is typically a reciprocal process,” Margolis says in Organizational Leadership . “You don't sit down and decide your direction, nor do you input your analysis of the external context into a formula and solve for a direction. Rather, setting direction is a back-and-forth process; you move between the value you'd like to create for customers, employees, investors, and your grasp of the context.”

5. Identify Necessary Behavior Changes

Once you’ve outlined activities that can provide value to your company, identify the behavior changes needed to address your organizational challenge statement.

“Your detective work throughout your root cause analysis exposes uncomfortable realities about employee competencies, organizational inefficiencies, departmental infighting, and unclear direction from leadership at multiple levels of the company,” Mayo says in Organizational Leadership .

Factors that can affect your company’s long-term success include:

- Ineffective communication skills

- Resistance to change

- Problematic workplace stereotypes

Not all root cause analyses reveal behaviors that must be eliminated. Sometimes you can identify behaviors to enhance or foster internally, such as:

- Collaboration

- Innovative thinking

- Creative problem-solving

6. Implement Behavior Changes

Although behaviors might be easy to pinpoint, putting them into practice can be challenging.

To ensure you implement the right changes, gauge whether they’ll have a positive or negative impact. According to Organizational Leadership , you should consider the following factors:

- Motivation: Do the people at your organization have a personal desire for and commitment to change?

- Competence: Do they have the skills and know-how to implement change effectively?

- Coordination: Are they willing to work collaboratively to enact change?

Based on your answers, decide what behavior changes are plausible for your root cause analysis.

7. Map Root Causes

The next step in your analysis is mapping the root causes you’ve identified to the components of organizational alignment. Doing so helps you determine which components to adjust or change to implement employee behavior changes successfully.

Three root cause categories unrelated to behavior changes are:

- Systems and structures: The formal organization component, including talent management, product development, and budget and accountability systems

- People: Individuals’ profiles and the workforce’s overall composition, including employees’ skills, experience, values, and attitudes

- Culture: The informal, intangible part of your organization, including the norms, values, attitudes, beliefs, preferences, common practices, and habits of its employees

8. Create an Action Plan

Using your findings from the previous steps, create an action plan for addressing your organizational problem’s root cause and consider your role in it.

To make the action plan achievable, ensure you:

- Identify the problem’s root cause

- Create measurable results

- Ensure clear communication among your team

“One useful way to assess your potential impact on the challenge is to understand your locus of control,” Mayo says in Organizational Leadership , “or the extent to which you can personally drive the needed change or improvement.”

The best way to illustrate your control is by using three concentric circles: the innermost circle being full control of resources, the middle circle representing your ability to influence but not control, and the outermost circle alluding to shifts outside both your influence and control.

Consider these circles when implementing your action plan to ensure your goals don’t overreach.

The Importance of Root Cause Analysis in Organizational Leadership

Root cause analysis is a critical organizational leadership skill for effectively addressing problems and driving change. It helps you understand shifting conditions around your company and confirm that your efforts are relevant and sustainable.

As a leader, you must not only effect change but understand why it’s needed. Taking an online course, such as Organizational Leadership , can enable you to gain that knowledge.

Using root cause analysis, you can identify the issues behind your organization’s problems, develop a plan to address them, and make impactful changes.

Are you preparing to transition to a new leadership role? Enroll in our online certificate course Organizational Leadership —one of our leadership and management courses —and learn how to perform an effective root cause analysis to ensure your company’s long-term success. To learn more about what it takes to be an effective leader, download our free leadership e-book .

About the Author

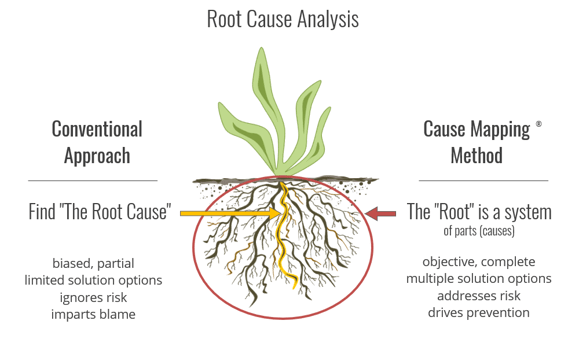

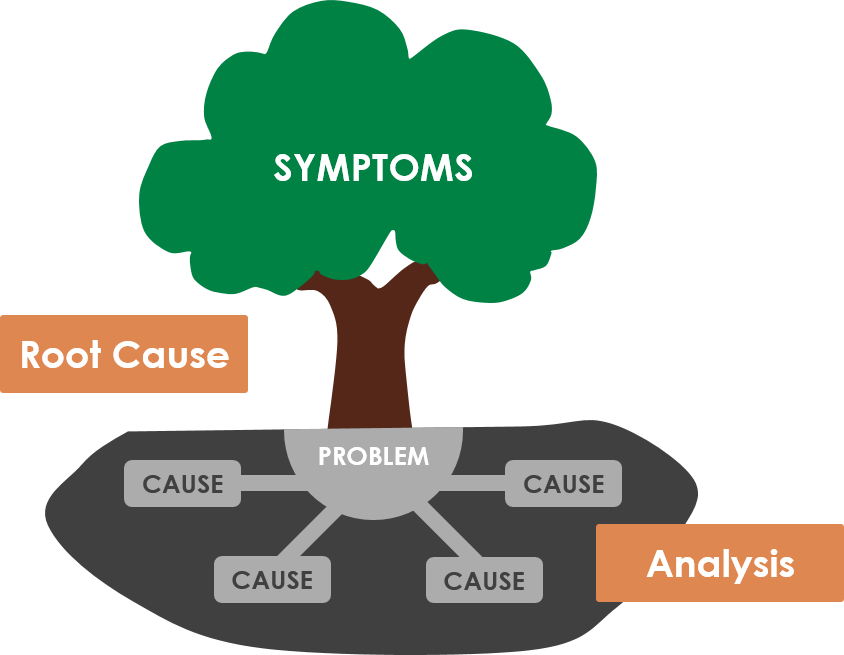

Root cause analysis (RCA) is the quality management process by which an organization searches for the root of a problem, issue or incident after it occurs.

Issues and mishaps are inevitable in any organization, even in the best of circumstances. While it could be tempting to simply address symptoms of the problem as they materialize, addressing symptoms is an inherently reactive process that all but guarantees a recurring—and often worsening—series of problems.

Ethical, proactive, well-run companies and organizations with a reactive approach will both encounter problems, but the former will experience fewer and recover faster because they prioritize root cause analyses.

Root cause analysis helps organizations decipher the root cause of the problem, identify the appropriate corrective actions and develop a plan to prevent future occurrences. It aims to implement solutions to the underlying problem for more efficient operations overall.

Learn how next-generation detection devices shift asset management services from routine maintenance regimes to predictive, AI-powered processes.

Delve into our exclusive guide to the EU's CSRD

Organizations perform root cause analyses when a problem arises or an incident occurs, but there are any number of issues that need an RCA. Triggers for a root cause analysis fall into three broad categories.

When real-world materials or equipment fails in some way (for example, a desktop computer stops working or a component from a third-party vendor delivers substandard performance).

When people make mistakes or fail to complete required tasks (for example, an employee fails to perform regular maintenance on a piece of equipment, causing it to break down).

A breakdown in a system, process or policy people use to make decisions (for example, a company fails to train team members on cybersecurity protocols, leaving the company vulnerable to cyberattacks ).

Organizations can conduct root cause analyses for a range or reasons, from commonplace email service disruptions to catastrophic equipment failures. Regardless of the nature or scope of the issue, performing root cause analysis should include the same fundamental steps.

If you have decided to conduct a root cause analysis, your department or organization is likely experiencing some acute issue, or at least looking to make substantive improvements to a particular process. Therefore, the first step of the root cause analysis process should be identifying and defining the problem that you want to address. Without a clearly defined problem, it is impossible to correctly identify the root causes.

When the department has a clear idea of the problem, it’s time to draft a problem statement spelling out the issue for everyone who will help with the RCA.

Once the issue is identified and clearly articulated to all involved parties, leadership should create a project charter, which will assemble a team to complete the analysis. The team should include a facilitator to lead the team through the analysis and any team members with either personal or professional knowledge of the systems, processes and incidents that you will investigate.

Data collection is the foundation of the problem-solving process. It is vital, at this stage, to find every piece of information that can help you identify contributing factors and ultimately the root causes of the issue. This can include collecting photographs and incident reports, conducting interviews with affected parties and reviewing existing policies and procedures. Some questions that you may want to ask during data collection:

- When did the problem start and how long has it been going on?

- What symptoms has the team observed?

- What documentation does the organization or department must prove that an issue exists?

- How will the issue affect employees and other stakeholders?

- Who is harmed or otherwise affected by the existence of this problem?

This is the most important step in the RCA process. At this point, the team has collected all necessary information and starts to brainstorm for causal factors. Effective root cause analyses require openness to all potential underlying causes of an issue, so everyone on the RCA team should enter the brainstorming stage with an open mind. Avoid attempts to determine root causes until every possibility is identified and vetted; starting the incident investigation process with preconceived notions may bias the results and make it more difficult to determine the real root cause.

Once the RCA team has an exhaustive list of possible causes and contributing factors, it is time to determine the root causes of the issue. Analyze every possible cause and examine the actual impact of each one to figure out which possibilities are the most problematic, which ones have similarities and which ones can be altogether eliminated. Be prepared for the possibility that there are multiple root causes to the issue.

After the team narrows the list of possibilities, rank the remaining potential root causes by their impact and the likelihood they are the root cause of the problem. Leadership will examine and analyze each possibility and collaborate with the RCA team to determine the actual root causes.

Once the team settles on root causes and has laid out all the details of the issue, they must start brainstorming solutions. The solution should directly address the root causes, with consideration for the logistics of executing the solution and any potential obstacles the team may encounter along the way. These elements will comprise the action plan that will help the team address the current problem and prevent recurrences.

While all RCAs will include the same basic steps, there are myriad root cause analysis methods that can help an organization collect data efficiently and effectively. Typically, a company will select a method and use root cause analysis tools, such as analysis templates and software, to complete the process.

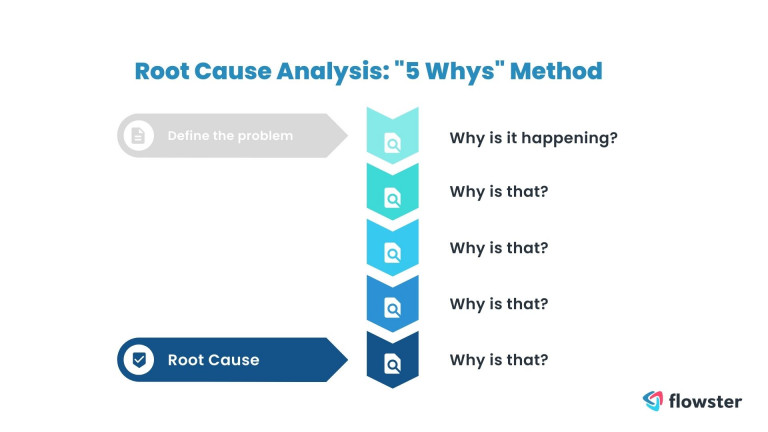

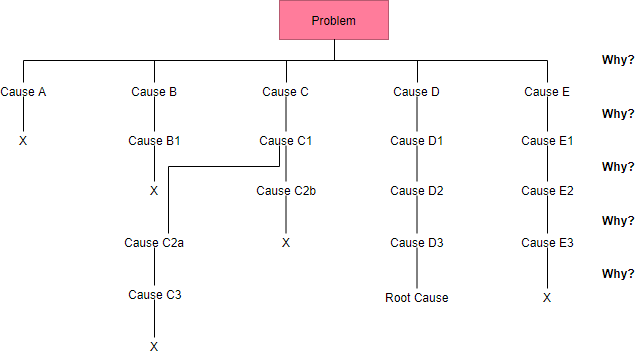

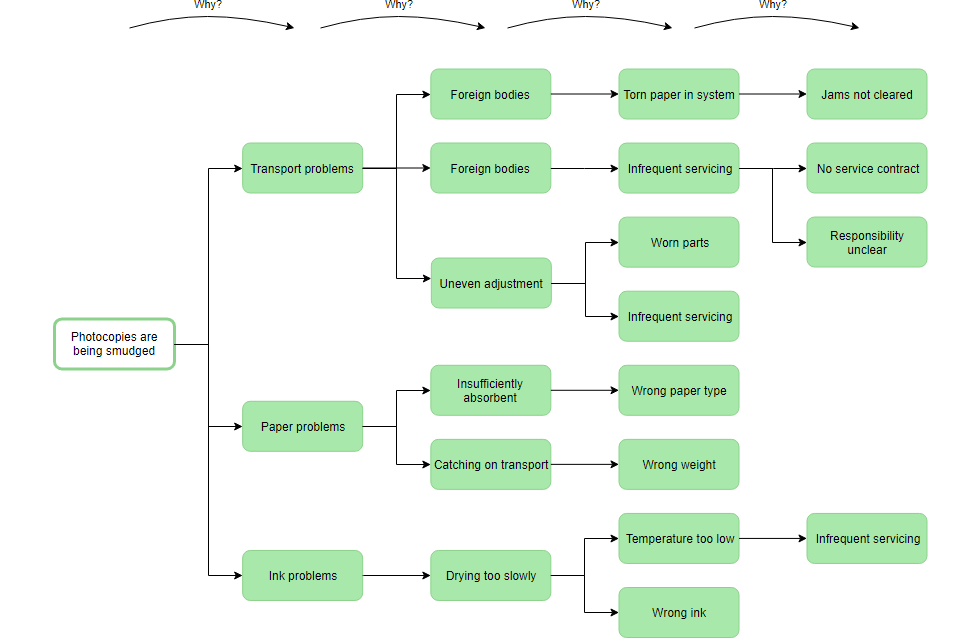

The 5 Whys approach is rooted in the idea that asking five “Why?” questions can get you to the root cause of anything. 5 Whys implores problem solvers to avoid assumptions and continue to ask “why” until they identify the root cause of a problem. In the case of a formalized organizational root cause analysis, a team may only need to ask three whys to find the root cause, but they may also need to ask 50 or 60. The purpose of 5 Whys is to push the team to ask as many questions as is necessary to find the correct answers.

A failure mode and effects analysis is one of the most rigorous approaches to root cause analysis. Similar to a risk analysis, FMEA identifies every possibility for system/process failure and examines the potential impact of each hypothetical failure. The organization then addresses every root cause that is likely to result in failure.

Pareto charts combine the features of bar charts and line charts to understand the frequency of the organization’s most common root causes. The chart displays root causes in descending order of frequency, starting with the most common and probable. The team then addresses the root cause whose solution provides the most significant benefit to the organization.

An impact analysis allows an organization to assess both the positive and negative potential impacts of each possible root cause.

Change analyses are helpful in situations where a system or process’s performance changed significantly. When conducting this type of RCA, the department looks at how the circumstances surrounding the issue or incident have changed over time. Examining changes in personal, information, infrastructure, or data, among other factors, can help the organization understand which factors caused the change in performance.

An event analysis is commonly used to identify the cause of major, single-event problem, like an oil spill or building collapse. Event analyses rely on quick (but thorough) evidence-gathering processes to recreate the sequence of events that that led to the incident. Once the timeline is established, the organization can more easily identify the causal and contributing factors.

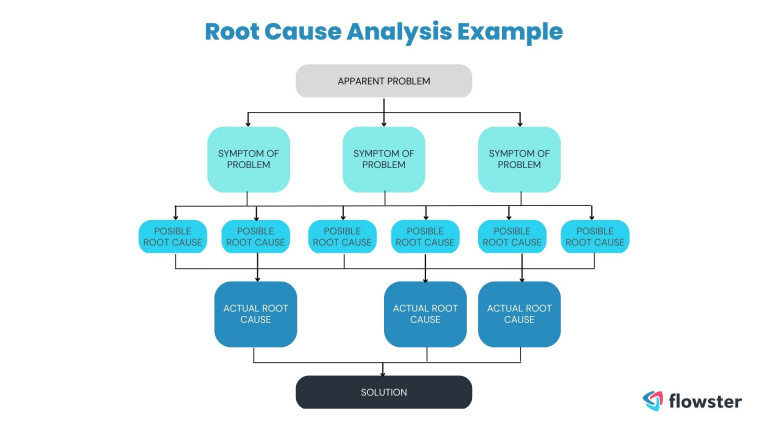

Also known as a causal factor analysis, a causal factor tree analysis allows an organization to record and visually display—using a causal factor tree—every decision, event or action that led to a particular problem.

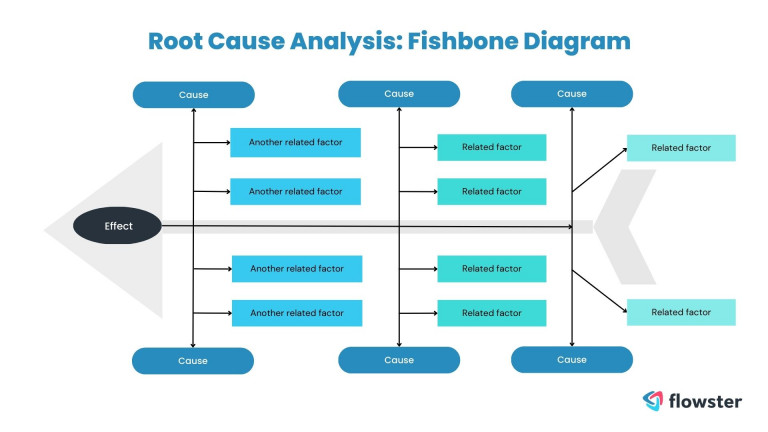

An Ishikawa diagram (or Fishbone diagram) is a cause-and-effect style diagram that visualizes the circumstances surrounding a problem. The diagram resembles a fish skeleton, with a long list of causes grouped into related subcategories.

DMAIC is an acronym for the Define, Measure, Analyze, Improve and Control process. This data-driven process improvement methodology serves as a part of an organization’s Six Sigma practices.

This RCA methodology proposes finding the root cause of an issue by moving through a four-step problem solving process. The process starts with situation analysis and continues with problem analysis and solution analysis, concluding with potential problem analysis.

An FTA allows an organization to visually map potential causal relationships and identify root causes using boolean logic.

Barrier analyses are based on the idea that proper barriers can prevent problems and incidents. This type of RCA, often used in risk management, examines how the absence of appropriate barriers led to an issue and makes suggestions for installing barriers that prevent the issue from reoccurring.

Companies that use the RCA process want to put an end to “firefighting” and treating the symptoms of a problem. Instead, they want to optimize business operations, reduce risk and provide a better customer experience. Investing in the root cause analysis process provides a framework for better overall decision-making and allows an organization to benefit from:

Continuous improvement : Root cause analysis is an iterative process, seeking not only to address acute issues, but also to improve the entire system over time, starting with the underlying cause. The iterative nature of root cause analysis empowers organizations to prioritize continuous process improvement.

Increased productivity : Preventing downtime, delays, worker attrition and other production issues within an organization saves employees time, freeing up bandwidth to focus on other critical tasks.

Reduced costs : When equipment breaks down or software bugs cause delays, organizations lose money and workers get frustrated. Root cause analysis helps eliminate the cost of continually fixing a recurring issue, resulting in a more financially efficient operation overall.

Better defect detection : When companies fail to address underlying issues, they can inadvertently affect the quality of the end product. Addressing persistent problems before they snowball protects the organization from revenue and reputational losses that are associated with product defects down the line.

Reduced risks : Improving business processes and systems keeps equipment running safely and helps workers avoid safety hazards in the workplace.

Intelligent asset management, monitoring, predictive maintenance and reliability in a single platform.

AIOps Insights is a SaaS solution that addresses and solves for the problems central IT operations teams face in managing the availability of enterprise IT resources through AI-powered event and incident management.

Enhance your application performance monitoring to provide the context you need to resolve incidents faster.

IBM research proposes an approach to detect abnormality and analyzes root causes using Spark log files.

Learn how IBM Instana provides precision hybrid cloud observability, metrics, traces and logs.

Downer and IBM are using smart preventative maintenance to keep passengers on Australia's light and heavy rail systems moving safely, reliably, comfortably and more sustainably.

Unlock the full potential of your enterprise assets with IBM Maximo Application Suite by unifying maintenance, inspection and reliability systems into one platform. It’s an integrated cloud-based solution that harnesses the power of AI, IoT and advanced analytics to maximize asset performance, extend asset lifecycles, minimize operational costs and reduce downtime.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

- All Products OSHA Medical Offices Dental Offices Veterinary & Animal Care Services Cal/OSHA Products WISHA Products OSHA Download COVID-19 HIPAA Medical & Dental Offices HIPAA Download Sexual Harassment Harassment Prevention Programs Online Training OSHA Training (Online) HIPAA Medical Training (Online) HIPAA Dental Training (Online) Cal/OSHA Training (Online) WISHA Training (Online) Dental CE Credits

- Testimonials

- Credentials

- Help Center

- Compliance 101 Blog

- Online Training Portal

- Compliance 101 – OSHA Compliance Tips | Gamma Compliance

- General Industry

What Is Root Cause Analysis and Why Is It Important?

If you’re a medical, dental, or veterinary professional, you may notice some recurrent issues in your practice that impact your team’s efficiency and patient satisfaction. You know you must make changes, but where do you start? This is where root cause analysis (RCA), a powerful problem-solving tool that can revolutionize how your organization tackles complex issues, comes in. If you’re not familiar with root cause analysis and why it’s important, keep reading to learn more.

What Is Root Cause Analysis?

Root cause analysis is a structured method used for identifying the underlying cause of a problem and addressing it to prevent its recurrence. It is a vital tool, as solving only the symptomatic aspect of a problem does not guarantee long-term sustainability, efficiency, or patient satisfaction. This is why understanding the core issue is essential.

Root Cause Analysis Steps

The process typically consists of several steps:

• Defining the problem: Clearly defining the identified issue is the first and most important step. Without a proper understanding of the problem, finding an effective solution is impossible. • Gathering data: Once you’ve identified the problem, collect relevant information to understand the situation. This may include interviewing team members, reviewing records, or conducting in-depth analyses of specific aspects of the problem. • Identifying possible causes: Using the data collected, pinpoint the potential underlying causes of the problem. At this stage, various root cause analysis techniques, such as "five whys," fishbone diagram, or failure mode and effect analysis (FMEA), can be beneficial. • Determining the root cause: Analyze the potential causes to identify the root cause or the core issue, which, once addressed, will prove to be most effective at preventing the recurrence of the problem. • Developing and implementing solutions: Once you identify the root cause, create and execute a plan to remedy the issue, implementing measures that will prevent the issue from re-emerging.

Importance of Root Cause Analysis

Now that you know what root cause analysis is, let’s explore why it’s important. There are two major types of RCA: corrective and preventive. Corrective RCA involves identifying and resolving the root causes of an existing problem, while preventive RCA focuses on identifying potential root causes of future issues and addressing them before they occur. By applying RCA effectively in both scenarios, your organization can enjoy a range of benefits, such as improved decision-making, reduced downtime, enhanced customer satisfaction, and limited accident and issue occurrences.

Now that you know what root cause analysis is and why it’s important, you can incorporate this process into your own practice. RCA is a critical tool for improving decision-making, reducing downtime, enhancing customer satisfaction, and limiting the occurrence of undesirable events, leading to ongoing success and growth for your organization. To learn more about root cause analysis and other OSHA practices, enroll in one of our online OSHA training courses from Gamma Compliance Solutions. Our training courses can help your business be more safe by bringing awareness to potential workplace hazards.

- Vet and Animal Care

- Product Updates

You have been successfully referred!

A 5% referral discount will be applied automatically in checkout.

tableau.com is not available in your region.

How it works

For Business

Join Mind Tools

Article • 8 min read

Root Cause Analysis

Tracing a problem to its origins.

By the Mind Tools Content Team

In medicine, it's easy to understand the difference between treating the symptoms and curing the condition. A broken wrist, for example, really hurts! But painkillers will only take away the symptoms; you'll need a different treatment to help your bones heal properly.

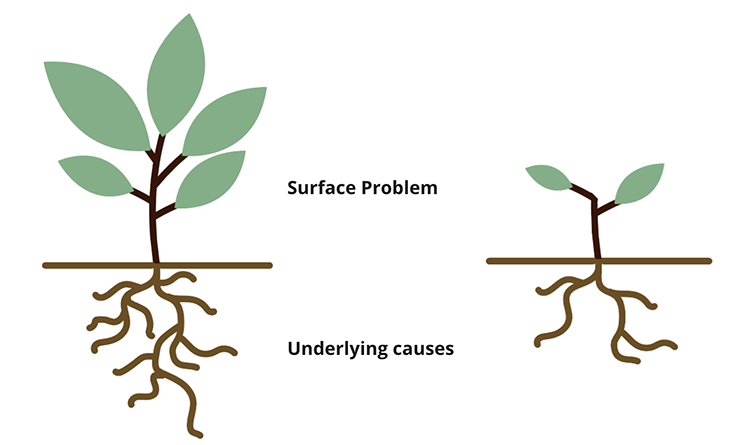

But what do you do when you have a problem at work? Do you jump straight in and treat the symptoms, or do you stop to consider whether there's actually a deeper problem that needs your attention? If you only fix the symptoms – what you see on the surface – the problem will almost certainly return, and need fixing over and over again.

However, if you look deeper to figure out what's causing the problem, you can fix the underlying systems and processes so that it goes away for good.

What Is Root Cause Analysis?

Root Cause Analysis (RCA) is a popular and often-used technique that helps people answer the question of why the problem occurred in the first place. It seeks to identify the origin of a problem using a specific set of steps, with associated tools, to find the primary cause of the problem, so that you can:

- Determine what happened.

- Determine why it happened.

- Figure out what to do to reduce the likelihood that it will happen again.

RCA assumes that systems and events are interrelated. An action in one area triggers an action in another, and another, and so on. By tracing back these actions, you can discover where the problem started and how it grew into the symptom you're now facing.

You'll usually find three basic types of causes:

- Physical causes – Tangible, material items failed in some way (for example, a car's brakes stopped working).

- Human causes – People did something wrong, or did not do something that was needed. Human causes typically lead to physical causes (for example, no one filled the brake fluid, which led to the brakes failing).

- Organizational causes – A system, process or policy that people use to make decisions or do their work is faulty (for example, no one person was responsible for vehicle maintenance, and everyone assumed someone else had filled the brake fluid).

RCA looks at all three types of causes. It involves investigating the patterns of negative effects, finding hidden flaws in the system, and discovering specific actions that contributed to the problem. This often means that RCA reveals more than one root cause.

You can apply RCA to almost any situation. Determining how far to go in your investigation requires good judgment and common sense. Theoretically, you could continue to trace the root causes back to the Stone Age, but the effort would serve no useful purpose. Be careful to understand when you've found a significant cause that can, in fact, be changed.

Frequently Asked Questions

Why is root cause analysis important.

RCA allows you to get to the true source of a problem, and stop it in its tracks. This is more effective than simply remedying the symptoms. By identifying and alleviating the root cause of a problem, you can prevent an issue from occurring again in the future.

What is the 5 Whys technique?

The 5 Whys is a common problem-solving technique. You simply ask "why" something is happening until you get to the source of the issue.

Though a useful tool in its own right, the 5 Whys method can be used during a Root Cause Analysis to help you quickly identify different causal factors of a problem.

What are the five steps of a root cause analysis?

RCA has five identifiable steps:

- Define the problem.

- Collect data.

- Identify causal factors.

- Identify root cause(s).

- Implement solutions.

Read on to learn how to carry out each step in your own root cause analysis.

How to Perform a Root Cause Analysis

Step one: define the problem.

Ask yourself the following:

- What do you see happening?

- What are the specific symptoms?

Step Two: Collect Data

- What proof do you have that the problem exists?

- How long has the problem existed?

- What is the impact of the problem?

You need to analyze a situation fully before you can move on to look at factors that contributed to the problem. To maximize the effectiveness of your RCA, get together everyone – experts and frontline staff – who understands the situation. People who are most familiar with the problem can help lead you to a better understanding of the issues.

A helpful tool at this stage is CATWOE . With this process, you look at the same situation from different perspectives: the Customers, the people (Actors) who implement the solutions, the Transformation process that's affected, the World view, the process Owner, and Environmental constraints.

Step Three: Identify Possible Causal Factors

- What sequence of events leads to the problem?

- What conditions allow the problem to occur?

- What other problems surround the occurrence of the central problem?

During this stage, identify as many causal factors as possible. Too often, people identify one or two factors and then stop, but that's not sufficient. With RCA, you don't want to simply treat the most obvious causes – you want to dig deeper.

5 Whys Root Cause Analysis

Use the 5 Whys tool to identify the root causes of a problem quickly. Just ask "Why?" until you reveal each causal factor.

If you need a more in-depth technique to identify possible factors, try these other tools that can help you dig further into each cause:

- Appreciation – Use the facts and ask "So what?" to determine all the possible consequences of a fact.

- Drill Down – Break down a problem into small, detailed parts to better understand the big picture.

- Cause and Effect Diagrams – Create a chart of all of the possible causal factors, to see where the trouble may have begun.

Step Four: Identify the Root Cause(s)

- Why does the causal factor exist?

- What is the real reason the problem occurred?

Use the same tools you used to identify the causal factors (in Step Three) to look at the roots of each factor. These tools are designed to encourage you to dig deeper at each level of cause and effect.

Step Five: Recommend and Implement Solutions

- What can you do to prevent the problem from happening again?

- How will the solution be implemented?

- Who will be responsible for it?

- What are the risks of implementing the solution?

Analyze your cause-and-effect process, and identify the changes needed for various systems. It's also important that you plan ahead to predict the effects of your solution. This way, you can spot potential failures before they happen.

One way of doing this is to use Failure Mode and Effects Analysis (FMEA). This tool builds on the idea of risk analysis to identify points where a solution could fail. FMEA is also a great system to implement across your organization; the more systems and processes that use FMEA at the start, the less likely you are to have problems that need RCA in the future.

Impact Analysis is another useful tool here. This helps you explore possible positive and negative consequences of a change on different parts of a system or organization.

Another great strategy to adopt is Kaizen , or continuous improvement. This is the idea that continual small changes create better systems overall. Kaizen also emphasizes that the people closest to a process should identify places for improvement. Again, with Kaizen alive and well in your company, the root causes of problems can be identified and resolved quickly and effectively.

Tips for Performing Effective Root Cause Analysis

Collaborate with other teams . Gain a diverse range of experiences and expertise by working with relevant people from other teams. They can likely offer different perspectives that will help to find the various causes of the problem.

Don’t play the blame game! Root cause analysis is a tool that helps you and your team overcome problems, but it shouldn’t be used to criticize or blame someone. Instead, try to create a blame-free culture, so that your co-workers feel confident in sharing ideas and insights. This will help you to diagnose the issue quickly and effectively.

Keep your questions open-ended. Leave any assumptions you have about the potential causes of the problem at the door. RCA is a chance to look at a problem with fresh eyes, so use open-ended questions as you work through the five steps. This will allow you to reveal things you didn’t already know, and find the most effective solution.

- Root Cause Analysis is a useful process for understanding and solving a problem.

- Figure out what negative events are occurring. Then, look at the complex systems around those problems, and identify key points of failure. Finally, determine solutions to address those key points, or root causes.

- You can use many tools to support your RCA process. Cause and Effect Diagrams and 5 Whys are integral to the process itself, while FMEA and Kaizen help minimize the need for RCA in the future.

- As an analytical tool, RCA is an essential way to perform a comprehensive, system-wide review of significant problems as well as the events and factors leading to them.

Download Worksheet

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Getting to the Root of a Problem Quickly

Using Root Cause Analysis

Find the Root of Your Problems

Add comment

Comments (0)

Be the first to comment!

Team Management

Learn the key aspects of managing a team, from building and developing your team, to working with different types of teams, and troubleshooting common problems.

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

SWOT Analysis

How to Build a Strong Culture in a Distributed Team

Mind Tools Store

About Mind Tools Content

Discover something new today

Top tips for delegating.

Delegate work to your team members effectively with these top tips

Ten Dos and Don'ts of Change Conversations

Tips for tackling discussions about change

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

5 ways to overcome networking nerves video.

Video Transcript

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

- Quality Management

Home » Free Resources » »

What is Root Cause Analysis? Process, Example & Everything You Need to Know

- Written by Contributing Writer

- Updated on March 7, 2023

Root cause analysis (RCA) is a problem-solving methodology used to identify the underlying cause of a problem, incident, or adverse event. Simply put, it is pinpointing the root of the problem to solve and prevent it from happening again.

When faced with a problem, we usually try to get to the bottom of it. For example, in the unfortunate event that we break our bones, we would be in immense pain. We might take measures to control the pain and blood loss. But our efforts don’t stop at simply having a painkiller and applying a bandage. We rush to the ER as soon as possible, get the necessary treatment to mend the broken bones, and make sure we are careful not to have such an accident.

What we did here is we analyzed the problem: the pain and took steps to fix the root cause, which is the broken bones. Here the pain is the symptom, and the fractured bone is the root cause.

Now that we are familiar with what it stands for let us dive deep into root cause analysis, or RCA, which is the systematic approach employed in various industries like healthcare, manufacturing, governmental organizations, aviation, etc. We also examine its definition, history, benefits, approaches, process, principles, tips, and how to learn more .

Defining RCA Analysis

Root cause analysis is a problem-solving process that seeks to identify the underlying cause of a problem or issue. It’s a systematic approach that goes beyond just identifying symptoms and aims to uncover the root cause of the problem. The objective is to prevent future occurrences of the situation by addressing its root cause.

RCA analysis involves collecting and analyzing data to identify a problem’s underlying cause. The process typically consists of a team of experts who use various tools and techniques to gather and analyze data. Once the root cause has been identified, the team develops a plan to address the root cause and prevent future occurrences of the problem.

Also Read: What Is Process Capability and Why It’s More Interesting Than It Sounds

History of Root Cause Analysis

The origins of root cause analysis can be traced back to the late 19th century when it was used in the manufacturing industry to improve production processes. In the 20th century, it was further developed and applied to a broader range of industries, including healthcare and aviation.

In the 1950s when manufacturers started to use it to understand industrial events. The primary goal of RCA is to determine the fundamental cause of a problem, which is referred to as the “root cause.”

One of the earliest adopters of RCA was Toyota, who employed the “5 whys” method, where the investigation of a breakdown or undesired event is conducted by asking “why” at least five times. This approach forces quality personnel to delve deeper and understand the underlying causes, layer by layer. Today, RCA is widely used in various industries to identify and eliminate problems, improve processes, and prevent recurrence.

RCA was first used in the healthcare industry to address adverse events and improve patient safety. The Institute of Healthcare Improvement (IHI) developed the RCA process in the late 1980s, and it quickly became a standard tool for improving patient safety and quality of care.

The Joint Commission, a US-based nonprofit that accredits healthcare organizations and programs, requires a root cause analysis (RCA) to be conducted whenever an accredited hospital experiences a specific type of adverse event. These are known as “sentinel” incidents, as they reveal a dangerous flaw in the care provided and prompt an immediate investigation and response.

RCA was developed in response to the growing number of plane crashes and incidents in the aviation industry. The National Transportation Safety Board (NTSB) was established in 1967. It has since been using RCA to investigate plane crashes and incidents to identify their root causes and prevent future occurrences.

Benefits of Root Cause Analysis

Before we go to explore how various industries and organizations benefit from implementing RCA, let us discuss the primary goals of root cause analysis.

The three main goals of RCA are:

- Identifying the root cause: The first goal is to discover the primary source of the problem or event. This is essential to understand the underlying causes and find practical solutions.

- Understanding the issues: The second goal of RCA is to fully comprehend the nature of the issues and develop a plan to fix, compensate, or learn from them. This requires a comprehensive analysis of the root cause and the factors contributing to it.

- Applying learnings: The third goal of RCA is to use the information gained from the analysis to prevent similar problems from occurring in the future. This includes making systemic changes to processes and systems and implementing measures to mitigate the risk of future adverse events.

Root cause analysis offers numerous benefits to organizations and industries. Some of the key benefits include:

- Improving quality: RCA helps organizations identify the root cause of problems and implement solutions to prevent future occurrences, improving quality and efficiency.

- Reducing risk: Organizations can reduce the risk of future incidents and adverse events by identifying the root cause of the problem and hence improving overall safety and security.

- Enhancing customer satisfaction: Organizations can better manage their product issues by addressing the root cause of problems. Thus organizations can improve customer satisfaction and trust.

- Improving organizational learning : RCA provides organizations with a systematic process for learning from problems and incidents, enabling them to improve their processes and procedures continuously.

- Increasing efficiency and productivity: Organizations can improve their processes and procedures by addressing the root cause of problems, leading to increased efficiency and productivity.

Also Read: Demystifying the Theory of Constraints

Top Approaches of Root Cause Analysis

There are several approaches to root cause analysis, each with its unique methodology and tools. Let’s discuss some of the most commonly-used types of root cause analysis.

The 5 Whys Root Cause Analysis

The 5 Whys root cause analysis approach is beneficial for solving simple problems or identifying root causes in a short amount of time. This simple yet effective approach involves asking “why” questions to identify the root cause of a problem. The process is repeated until the root cause is identified. For example, in a service industry setting, in case of a complaint, by asking “why” five times, the team could drill down layer by layer to understand the underlying causes of the problem, such as poor communication, inadequate training, or poor service quality.

Fishbone Diagram

The Fishbone Diagram is a visual tool that helps teams identify potential root causes of a problem. It is called so because it resembles a fishbone. The fishbone diagram organizes and categorizes possible causes, making it easier to identify the root cause. For example, a fishbone diagram could be used in a manufacturing setting to categorize and analyze the various factors contributing to a machine breakdown, such as equipment design, operator error, or poor maintenance.

Pareto Analysis

The Pareto Analysis approach uses statistical analysis to identify the most significant root causes of a problem. The Pareto principle states that 80 percent of issues are caused by 20 percent of root causes. Pareto analysis helps teams focus on the most critical root causes, reducing the time and resources required to address the problem. For example, in a healthcare setting, a Pareto analysis could determine that 20 percent of patient falls are caused by 80 percent of the root causes, such as slippery floors, poor lighting, or lack of staff supervision.

Fault Tree Analysis (FTA)

This type of root cause analysis is a graphical representation of the relationships between different system components and how they contribute to a problem or failure. FTA helps teams understand the interdependencies between various components and identify the root cause of a problem. For example, in an aviation setting, an FTA could be used to analyze the interdependencies between different components of a plane, such as the engines, fuel system, and control surfaces, and to identify the root cause of a crash.

Conducting Root Cause Analysis: Process

We can break the process of conducting RCA into the following steps:

- Define the problem: The first step is clearly defining the problem and understanding what needs to be addressed.

- Gather data: Once the problem is defined, the next step is to gather data. This involves collecting information about the problem, including date, time, and location, as well as any relevant documentation, reports, or other information.

- Form a team: The next step is forming a team of experts responsible for conducting the RCA. The team should include individuals with expertise in the problem area, as well as representatives from different departments or parts of the organization.

- Use a root cause analysis tool: The team should use a root cause analysis tool, such as a fishbone diagram, Pareto analysis, or fault tree analysis, to help identify potential root causes.

- Identify root causes: Once potential root causes have been identified, the team should use the data and information collected to validate and verify the root causes.

- Develop solutions: Once the root cause has been identified, the team should develop solutions to address the root cause and prevent future occurrences of the problem.

- Implement solutions: The final step is to implement the solutions and monitor their effectiveness to ensure that the problem has been fully resolved.

Also Read: Value Stream Mapping in Six Sigma

Root Cause Analysis Principles

Conducting RCA involves following several fundamental principles:

- Root cause focus: Root cause analysis focuses on discovering and correcting the root causes of a problem rather than just treating the symptoms.

- Short-term relief: While focusing on root causes is essential, it’s also important to provide short-term relief for the symptoms.

- Multiple root causes : Multiple root causes can contribute to a problem, so it’s important to identify all of them.

- No blame: The focus should be on understanding how and why a problem occurred rather than who was responsible.

- Evidence-based: Root cause claims should be supported by concrete cause-and-effect evidence.

- Actionable information: The results of the analysis should provide enough information to inform a corrective course of action.

- Future prevention: Consideration should be given to how the root cause can be prevented from recurring.

Tips for Root Cause Analysis

- Start with a clear definition of the problem: It is essential to have a crystal-clear understanding of the problem before starting the RCA process. This will help ensure that the team is focused on addressing the right issue and that the root cause is accurately identified.

- Gather all relevant data: Data is essential for a successful RCA. The team should gather as much relevant data as possible, including the date, time, and location of the problem, as well as all pertinent documentation, reports, or other information.

- Involve experts from different areas: Involving experts from different areas of the organization, such as operations, maintenance, and engineering, will help ensure that the root cause is accurately identified and that all potential root causes are considered.

- Use multiple tools and techniques: Different RCA tools and techniques, such as fishbone diagrams, Pareto analysis, and fault tree analysis, can provide different perspectives and insights into the root cause of a problem. The team should consider using multiple tools and techniques to ensure they completely understand the problem.

- Be thorough and systematic: RCA should be approached systematically, using a structured process and methodology to identify root causes. The team should be detailed and methodical in their approach to ensure that all potential root causes are considered and that the root cause is accurately identified.

- Focus on prevention: The goal of RCA is not just to identify the root cause of a problem but to prevent future occurrences. The team should focus on developing solutions that will prevent the problem from happening again in the future.

Also Read: Demystifying Kaizen Lean Six Sigma

Master Root Cause Analysis Skills to Become a Lean Six Sigma Expert

For a Lean Six Sigma expert, the ability to identify the underlying causes of problems and develop effective solutions for improving processes and outcomes is a prized skill. As such, you need to understand and know how to perform root cause analysis.

If you’re interested in becoming a Lean Six Sigma expert, an online Lean Six Sigma certification can provide you with the knowledge, skills, and tools you need to succeed in this role.

An online bootcamp like the one delivered by Simplilearn, in collaboration with the University of Massachusetts, covers the core concepts of Lean Six Sigma, including problem-solving methodologies, process improvement techniques, and statistical analysis tools. This IASSC-accredited program teaches how to identify and eliminate waste, reduce defects, and improve process efficiency across various industries.

With business mentoring from industry experts from KPMG, you’ll be able to tackle real-world business problems confidently. This fast-track program is perfect for quality professionals, business analysts, and executives looking to carve successful careers.

Ready to start your journey toward becoming a master in quality management? Enroll today!

You might also like to read:

Ultimate Guide to Six Sigma Control Charts

DMADV: Everything You Need to Know

Describing a SIPOC Diagram: Everything You Should Know About It

Process Mapping in Six Sigma: Here’s All You Need to Know

How to Use the DMAIC Model?

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Recommended Articles

What Is Lean Management? Principles & Everything You Need to Know

Discover the essence of lean management – a powerful approach to streamline processes and maximize efficiency. Explore its principles and benefits in our comprehensive guide.

What is Process Mapping in Six Sigma? Here’s Everything You Need to Know

Demystifying Process Mapping in Six Sigma: Learn to optimize workflows and enhance quality. Dive into this essential quality management tool.

Six Sigma Black Belt Salaries in 2024: Everything You Need to Know!

Get to know about salaries and factors affecting six sigma black belt salary and the skills required to have an incremental effect on your pay scale.

A Guide to Failure Mode and Effects Analysis

Explore Failure Mode and Effects Analysis with our easy-to-understand guide. Learn what it is, why it’s useful, how to use it, and its key applications.

A Guide to Design of Experiments in Six Sigma

In today’s hypercompetitive world, organizations must streamline their operations and workflows to stay ahead of the game. Lean Six Sigma and the design of experiments are methodologies that can help them do this. Learn more in this article.

A Guide to Six Sigma Projects

Originally developed for manufacturing processes, the Six Sigma methodology is now leveraged by companies in nearly all industries. In this article, we will share information about successful Six Sigma projects, methods, and more.

Lean Six Sigma Certification

Learning Format

Online Bootcamp

Program benefits.

- Green and Black Belt exam training material included

- Aligned with IASSC-Lean Six Sigma

- Masterclasses from top faculty of UMass Amherst

- UMass Amherst Alumni Association membership

Elasticsearch Platform

Observability, security, and search solutions — powered by the Elasticsearch Platform.

Search and analytics, data ingestion, and visualization – all at your fingertips

- Elasticsearch

- Integrations

Elastic Cloud

Find answers that matter with Elastic on your preferred cloud provider.

- Observability

Unify app and infrastructure visibility to proactively resolve issues.

- Log monitoring

- Application performance monitoring

- Infrastructure monitoring

- Synthetic monitoring

- Real user monitoring

- Universal profiling

- OpenTelemetry

Protect, investigate, and respond to cyber threats quickly and at scale.

- Continuous monitoring

- Threat hunting

- Investigation and incident response

- Automated threat protection

Accelerate search results across any cloud and increase personalization.

- Generative AI

- Vector database

- Search applications

- Workplace search

- Customer support

By industry

- Public sector

- Financial services

- Telecommunications

- Retail and Ecommerce

- Manufacturing and automotive

By solution

Give customers the flexibility, speed, and scale to find what's next.

Customer spotlight

Learn how Cisco transforms its search experience with AI

Learn how RWE powers its renewable energy trading business

Learn how Comcast boosts engineering velocity and innovation

Dive in to everything related to code, forums, and groups.

- Search Labs

Stay up to date with the latest tech topics, innovations, and news.

Grow your skills and open doors for future success.

- Getting started

- Elastic resources

- Consulting services

- Trainings & certifications

- Security Labs

Find the support you need, no matter the topic.

- Support center

See what's happening at Elastic

See our demo gallery

Get started with Elasticsearch

What's new in Elastic 8.13

What is root cause analysis (RCA) in software development?

Root cause analysis definition.

Root cause analysis (RCA) is a proven troubleshooting technique used by software development teams to identify and resolve problems at their core, rather than attempting to treat symptoms. Root cause analysis is a structured, step-by-step process designed to seek out primary, underlying causes by gathering and analyzing relevant data and testing solutions that address them.

Why is root cause analysis important?

Root cause analysis is essential in software development because the systematic approach allows teams to troubleshoot more efficiently and develop long-term solutions that prevent issues from recurring. By addressing the root causes of errors and defects, developers can ensure their systems are stable, reliable, and efficient, reducing costly downtime and speeding up the development process. RCA also helps developers prioritize issues based on their impact and severity, empowering them to tackle the most critical problems first.

How to conduct a root cause analysis

Applied as a problem-solving method across industries and disciplines— from science and engineering to manufacturing and healthcare— root cause analysis requires following a specific series of steps to isolate and understand the fundamental factors contributing to a flaw or failure in a system. The steps involved in conducting root cause analysis in software development follow the same universal RCA principles:

- Step 1: Define the problem and set up alerts (if possible) The first step in RCA is to define the problem and make sure it’s clearly understood. This could include setting up alerts to monitor for potential issues like abnormal application behavior, system performance degradation, or security incidents.

- Step 2: Gather and analyze data to determine potential causal factors Once the problem has been defined, the next step is to gather and analyze data. This may include reviewing system logs, application performance metrics, user feedback, and other relevant data sources. The data evaluation should lead to a list of potential causal factors that could be contributing to the problem.

- Step 3: Determine root causes Once the data analysis in Step 2 is complete, use one of several RCA methods to analyze the data and potential causal factors to discover the actual root cause (or causes) of the problem. The root cause analysis should suggest corrective actions.

- Step 4: Implement solutions and document actions After the root cause has been identified, the last step is implementing solutions to address the problem. This may include changes to code, configuration settings, or any number of system adjustments. It’s important to document all actions taken to address the problem to ensure they’re effective and can be repeated if necessary.

Methods and techniques for root cause analysis outside of the software world

There are many useful tools developed to aid in achieving effective RCA. When brainstorming and analyzing potential causes, these methods allow you to visualize and organize information into a usable framework for solving problems. Popular techniques for root cause analysis include:

- 5 Whys The 5 Whys is a problem-solving strategy that helps get to root causes by iterating on “Why” questions until the immediate causes of a problem are identified. When teams ask" why" multiple times, with each question leading logically to the next, it encourages critical thinking and deeper digging, helping to prevent superficial or surface-level solutions.

- Pareto chart A Pareto Chart is a combination bar chart and line chart that maps out the frequency of the most common root causes of problems, starting with the most probable. Based on the Pareto principle, which states that 80% of the effects come from 20% of the causes, the chart lists causes in order of importance and shows the cumulative impact of each, helping teams prioritize the causes that have the most significant impact on the problem.

- Scatter plot diagram A scatter plot diagram uses dots to help teams identify patterns in data that could be contributing to a problem. Plotting two numeric variables on a graph makes it easier to find any correlation between them. The technique can help you quickly identify any significant relationships between variables and identify outliers, which could be the potential causes you're looking for.

- Fishbone diagram Resembling a fish skeleton, this visual tool provides a graphic representation of the factors that could be contributing to a problem, with the head representing the issue and the bones representing the categories of potential causes. It is particularly effective at fostering collaboration among teams and can help lead to a more comprehensive understanding of the problem.

- Failure Mode and Effects Analysis (FMEA) FMEA is a structured, empirical approach that helps to identify potential failures and their effects. It is a systematic method that involves identifying potential failure modes, evaluating their severity, and determining the likelihood of occurrence and detection — then ranking them by their potential risk score. It can help teams focus on the most important issues to tackle first and also help prevent problems before they occur.

Root cause analysis tools for software developers

In the software world, RCA can expose root problems deep in the code. But the use of cloud-native technologies and the complexity of today's modern applications make it increasingly difficult to determine the root cause of issues. Teams can use observability and security tools to achieve powerful RCA results, for example:

Observability Observability provides real-time insight into software performance and behavior through data collection and analysis, allowing you to identify issues and gain visibility into root causes by monitoring metrics, logs, and traces, and through AIOps and observability tools like:

- Machine learning and AIOps Search, visualization, and machine learning can help identify anomalies and surface the root cause of an issue. This can help you make informed decisions and take corrective action quickly.

- Distributed tracing Tracking and analyzing the flow of requests through complex distributed systems with distributed tracing provides insight into the interactions between components and services, which can help identify bottlenecks and other issues that could be causing problems.

- Log pattern analysis Analyzing log patterns and trends generated by applications and infrastructure to identify the root cause of a problem—as well as detect anomalies, errors, and other issues that could be impacting software performance.

- Service dependency mapping By identifying the relationships and dependencies between different components in a system, you can automatically map service dependencies that might be causing issues and understand how changes in one component impact the rest of the system.

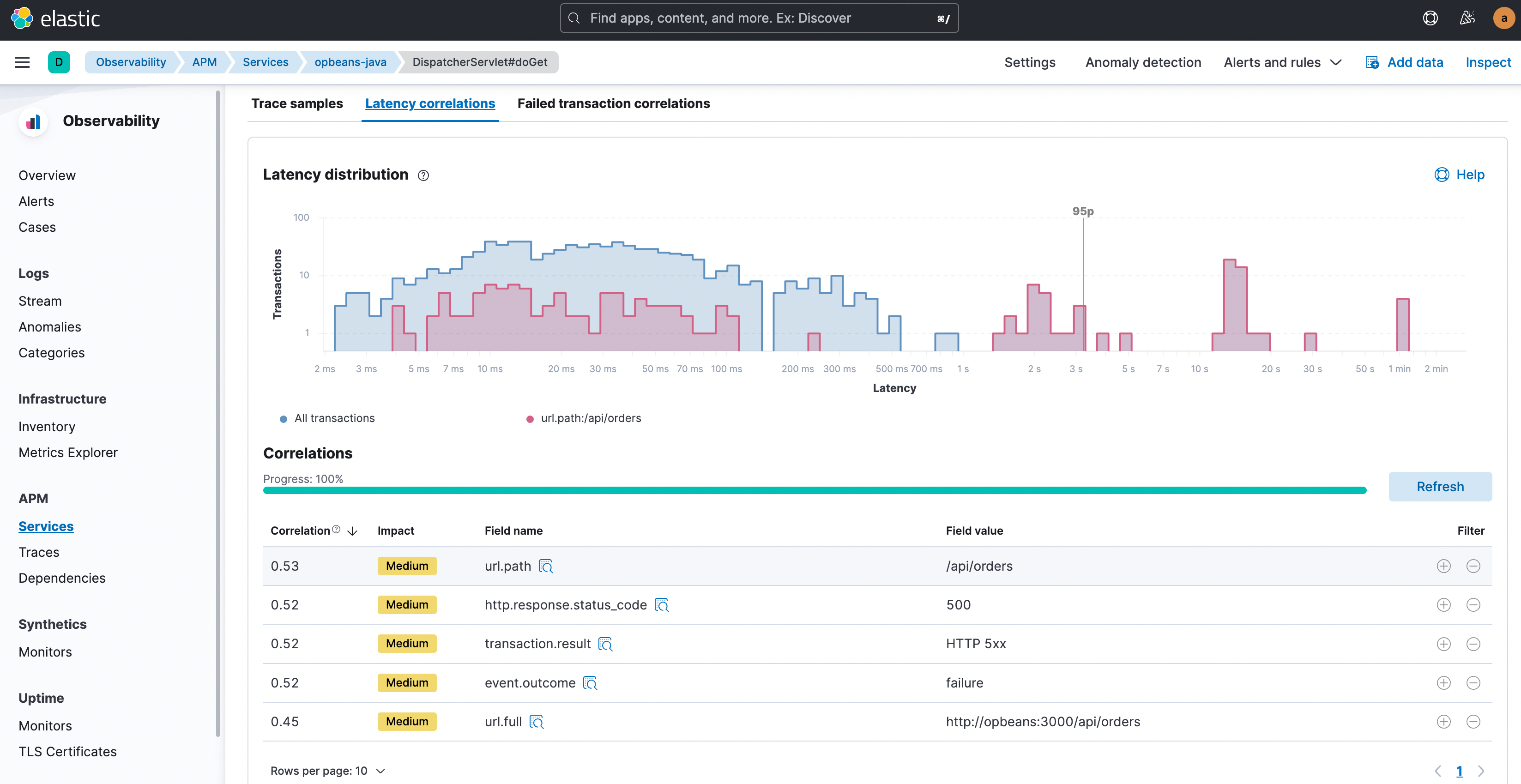

- Latency and error correlations Analyzing data related to latency and error rates to identify correlations between the two, you can spot patterns and relationships between errors and performance issues that can help pinpoint root causes.

Security Analyzing security-related data to identify vulnerabilities and weaknesses in the system is an important aspect of root cause analysis. It can help prevent security breaches and other issues that could impact software performance.

- Unsupervised anomaly detection provides an additional layer of defense Comprehensive security requires multiple layers of threat protection. Unsupervised machine learning identifies deviations from normal activity in your data, without having to specify what's abnormal, and can catch attacks that standard approaches to threat hunting are likely to miss.

- Investigating threats and exploring correlations Analyzing security data related to detected events helps determine whether they represent actual threats, or can be ignored. Security analysts recognize malicious activity by looking at patterns in sessions, event timelines, and diagnostic information from hosts.

Common mistakes to avoid with root cause analysis

Root cause analysis can be incredibly effective for identifying and resolving problems, but there are several common mistakes teams should be aware of:

- Lack of data validation: Failing to validate the data used in your analysis can lead to incorrect conclusions and ineffective solutions.

- Selecting solutions as causes: Issues like lack of training and support or budget constraints are rarely the root cause of a problem. They're far more often the solutions. It's critical to dive deeper to trace a problem to its origins.

- Need to find one cause: There can be many contributing factors that lead to a problem, and it's important to identify all of them, rather than landing on one that's convenient.

- Not involving the right people: Valid, truly effective RCA requires input from all relevant stakeholders, including software developers, testers, and business analysts.

Benefits of root cause analysis

The benefits of root cause analysis in software development are enhanced troubleshooting, reduced costs, and greater efficiency — all of which lead to a better product and a happier customer. Root cause analysis is a critical component of software development, helping teams identify the origins of fundamental errors and how to fix them. RCA also allows teams to stop problems from happening again.

- Helps to prevent problems from recurring: RCA enables teams to implement solutions that address root causes rather than just symptoms. By preventing problems from recurring, teams can save time, reduce costs, and improve the overall quality of their software. For example, a software team may notice that a particular feature of an application is consistently crashing. By performing RCA, they might discover the issue stems from a particular set of user inputs that aren’t being handled properly. With this information, they can implement a correct solution that stops the issue in its tracks.

- Improves process efficiency: By identifying root causes, teams can optimize their processes to prevent similar issues from occurring, leading to increased efficiency, reduced downtime, and a more streamlined development process. If a dev team finds their continuous integration pipeline repeatedly failing due to issues with their test suite, they can perform RCA to find out if the problem is slow-running tests causing the pipeline to time out. Now they can optimize their test suite to avoid similar problems in the future.

- Prevents customer dissatisfaction: Root cause analysis helps teams address issues that could impact customer satisfaction. If, for example, a team receives user complaints about a feature being too slow to load, they might use RCA to determine that the issue is a poorly optimized database query. By implementing solutions to prevent that problem from recurring, like optimizing the query to improve performance, they can deliver a more positive user experience. When software consistently meets customer expectations, it goes a long way in building trust and loyalty, which can ultimately lead to increased revenue and long-term growth.

Tips for performing root cause analysis

- Pull information from multiple sources, and understand your data When performing root cause analysis, data quality, visibility, and comprehension are paramount. Elastic offers a solution that consolidates all your data in one system. You get data visualization in Kibana and interactive tools that allow you to dig deep into observability issues and investigate security incidents.

- Get multiple eyes on the data and the problem by working with a team Elastic features extended support for personalized collaboration in Kibana and O11y, helping you streamline workflows and facilitate escalations with your team.

- Take notes Elastic offers streamlined alerts and case management , allowing you to reach insights faster with richer context for your data and visualizations, including sourcing annotations dynamically from Elasticsearch queries in Kibana. For query-based annotations, you also have the ability to manually annotate Kibana Lens visualization with notes.

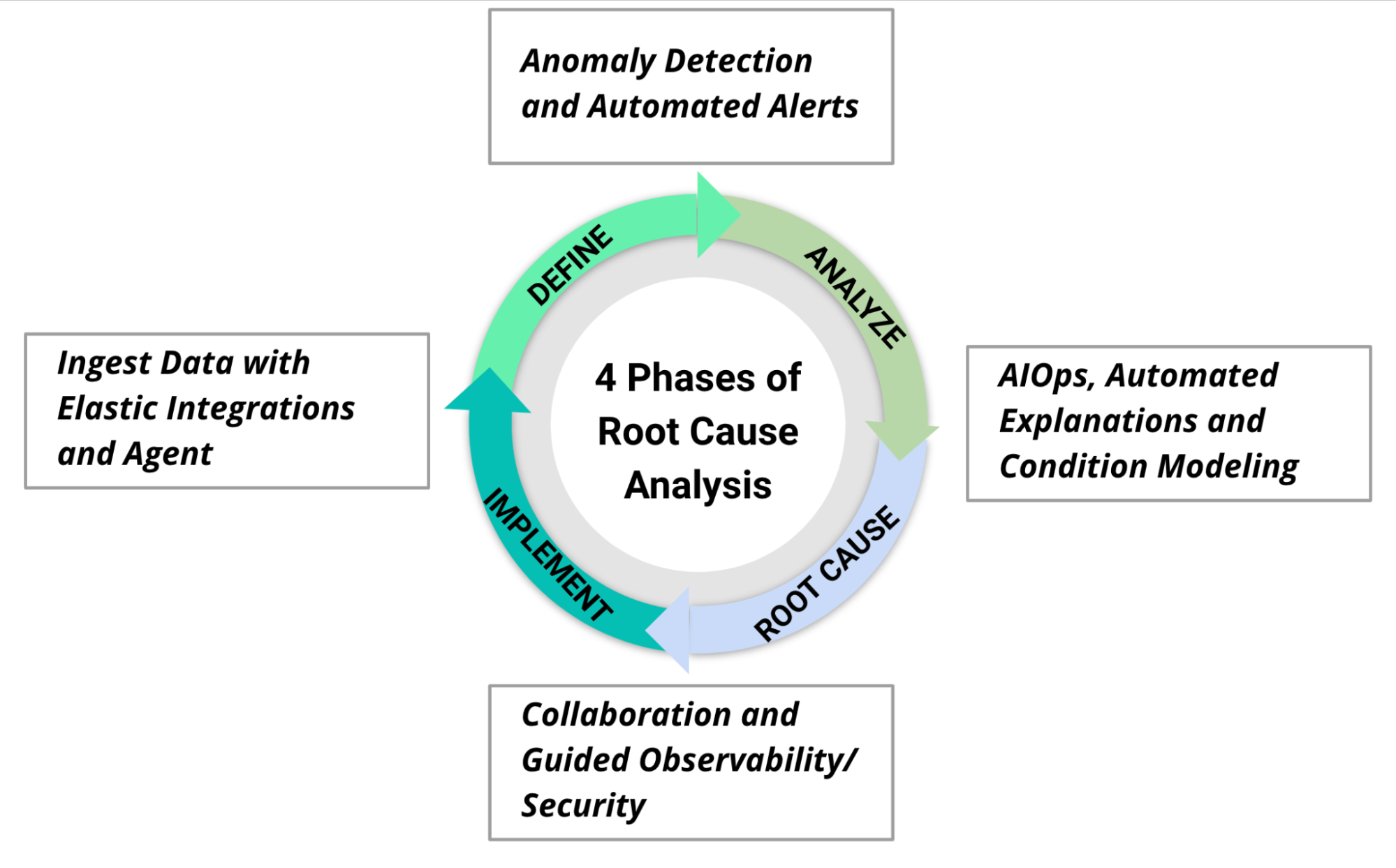

Root cause analysis with Elastic

The Elasticsearch Platform and its built-in solutions — Elastic Enterprise Search , Elastic Observability , and Elastic Security — act collectively as a jet engine for facilitating root cause analysis. As the most widely deployed solution for transforming metrics, logs, and traces into actionable IT insights — Elastic Observability enables you to unify observability across your entire digital ecosystem. Further, analysts recognized Elastic Security as a leader in security analytics and SIEM.

Specifically, the following capabilities accelerate root cause analysis in its various phases:

- Ingest your data with Elastic Agent and hundreds of integrations .

- Receive automated notifications of potential issues using pre-configured alerts and anomaly detection, effectively putting your monitoring on "auto pilot"

- Apply machine learning and AIOps to process large data sets at scale, with interactive features tailor-made to facilitate RCA for observability, including APM correlations and Explain log rate spikes , and for security investigations with features like Session View , Event timeline , and query hosts for diagnostic information using Osquery .

- Determine causal factors using guided journeys and collaborate on root cause and appropriate solutions to fix and prevent the problems using Elastic case management .

To help your team get the most out of root cause analysis, start a free trial and discover what Elastic can do for you.

Root cause analysis resources

- Root cause analysis for logs

- Automate anomaly detection and accelerate root cause analysis with AIOps

- Why you need AIOps as part of your observability strategy

- Elastic Security for SIEM & security analytics

- Elastic Security for automated threat protection

- Accelerate security investigations with machine learning and interactive root cause analysis in Elastic

- Apply Elastic to root cause analysis in manufacturing

- Predictive maintenance in industrial IoT

Advisory boards aren’t only for executives. Join the LogRocket Content Advisory Board today →

- Product Management

- Solve User-Reported Issues

- Find Issues Faster

- Optimize Conversion and Adoption

Better problem solving with root cause analysis (with template)

If you walk into your kitchen to find your favorite vase smashed on the floor, it might be safe to assume that the grinning cat nearby was the root cause of this problem. If only it was this simple in business and we could just say “the cat did it.” Product problems are often much more complex and connected to a variety of root causes.

If you think of a weed, the surface is only the problem you can immediately see. However, if you cut the weed from the ground level, it’s likely to grow back from the root. This is just like fixing product problems with a band-aid with little to no investigation of a root cause — it’s likely to return.

These types of problems need a more thorough root cause analysis (RCA) to determine how, and why the problem happened, and how to prevent it in the future.

What is root cause analysis?

Root cause analysis is a tool you can utilize when determining the true cause of a problem. You might have assumptions about what the cause of a problem might be or experience biases towards one as the main cause.

Performing a root cause analysis can help you determine what the underlying causes of a problem are to help address a more impactful and valuable solution:

What are the 4 steps in a root cause analysis?

When you’re trying to uncover the roots of a problem, it can be daunting to figure out where to start. The process to conduct a root cause analysis can be broken down into a few easy steps:

- Define the problem

- Identify and map the problem causes

- Identify the evidence that supports your causes

- Create a root cause analysis report and set up your action plan

1. Define the problem

A clear definition of the problem is the first step. Sometimes problems are easy to identify, like a broken link. More often, problems can be abstract and need clarification, like a decrease in overall purchases through a site or an increase in bugs reported.

Here are some more examples of problems:

- A 20 percent drop in customer purchases placed from the shopping cart page from the previous week

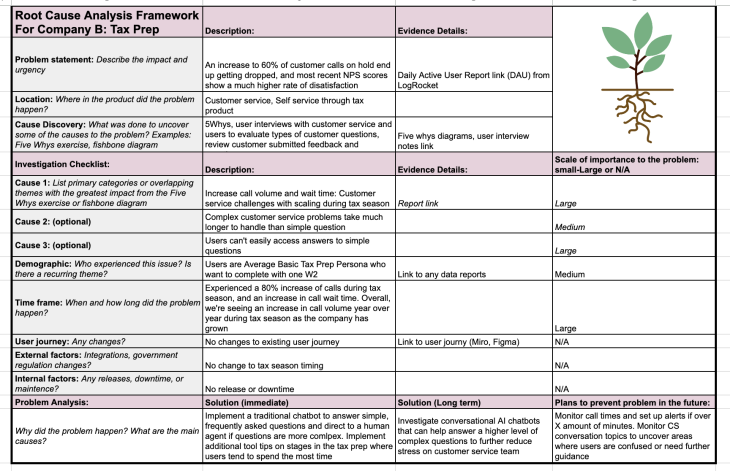

- 60 percent of customers on hold end up dropping their call and, as a result, the company has experienced a decrease in NPS scores

- A 40 percent increase of customer reported issues with using the folders feature in a CRM

- A 15 percent decrease in user engagement with a core feature on a social media site

It’s also critical to understand how to define a problem:

2. Identify and map the problem causes

Using tools like a fishbone analysis and the Five Whys framework can help you put together causes and start to categorize themes of the problem. When going through a Five Whys diagram, try to come up with a few alternate pathways and you might notice overlapping areas.

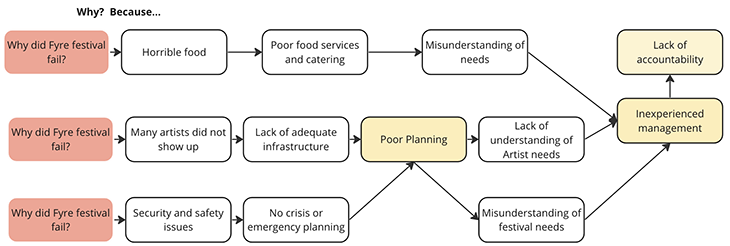

Each example of a Five Whys diagram is accurate, but only looking at one cause can prevent you from understanding the fuller picture. For example, there was more than one reason why the Fyre Festival failed and it’s important to identify overlapping themes to avoid leaning on only one cause:

In a product example, there might be numerous reasons why session times have decreased, or user reported bugs are up.

After evaluating the size, impact, general cause themes, and urgency of the problem, you’ll have a better understanding of how much effort will be needed for the analysis. The larger the problem on the surface, the more underlying causes you might find. Even simple problems can sometimes have numerous causes to consider and you need to determine how in-depth you need to dig to “unroot” the causes.

It’s also critical to check all your bases. Once you have evaluated and categorized the different potential causes to a problem, use the following as a checklist to ensure you’re covering all areas of where and how this problem happened. Be sure to identify any changes or recent events that might have occurred that could have impacted the problem.

- Demographics : is the problem happening to one specific demographic? Only happening to iPhone users? Users in a specific location?

- Time specific : when did the problem happen? Is it continuing to happen? Did the problem only occur during a specific time? You might discover that the problem is related to a time-specific cause, like a release or outage

- User journey : did anything change within the user journey? Map the workflow to determine if any new developments have occurred

- External factors : is this an issue with a third party integration? Did a competitor launch a successful new feature that might be taking business from you? Some of these external factors could be out of your control, but important to recognize

- Internal factors : how many feature releases happened during this time frame? Was there any product downtime or maintenance at that time?

3. Identify the evidence that supports your causes

Collecting evidence is a key part of a root cause analysis. Without evidence, your problem causes are based on assumptions and potentially harmful biases.

Start evaluating any data you might have available. Using session replay tools like LogRocket can help you collect evidence of the problem. Here are a couple of examples of the type of data that can be used to collect evidence:

- User count — number of users impacted by the problem

- Usage — daily, weekly, or monthly active users and a decrease or increase in session time

- Decrease or increase in events — for example, a decrease in users selecting the Add to cart button from a page or an increase in error pages

- Error tracking and user frustration — tools like LogRocket can help track where things are going wrong in your product and surface critical issues

- Qualitative evidence — run user interviews or user-submitted feedback with tools like Loom. Are multiple users running into the same roadblock? Are you seeing the same complaint from multiple users in feedback tickets?

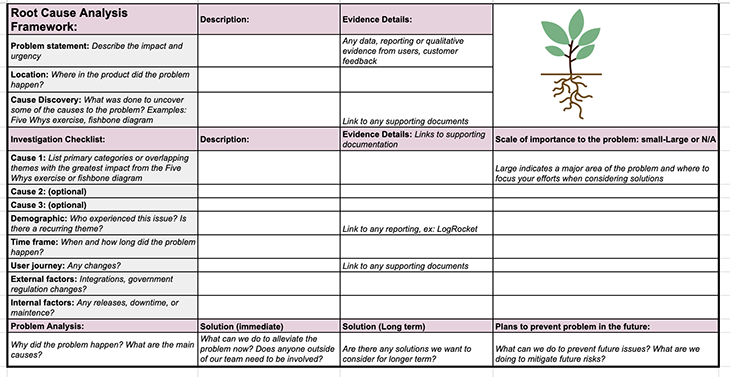

4. Create a root cause analysis report and set up your action plan