Undergraduate Programs

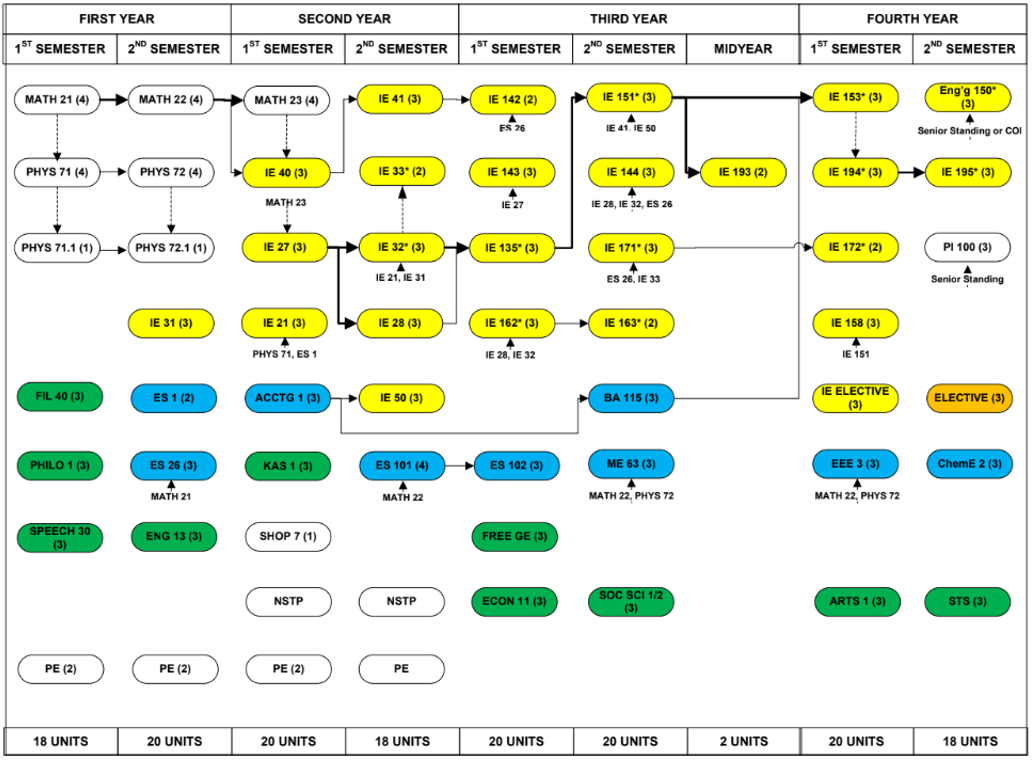

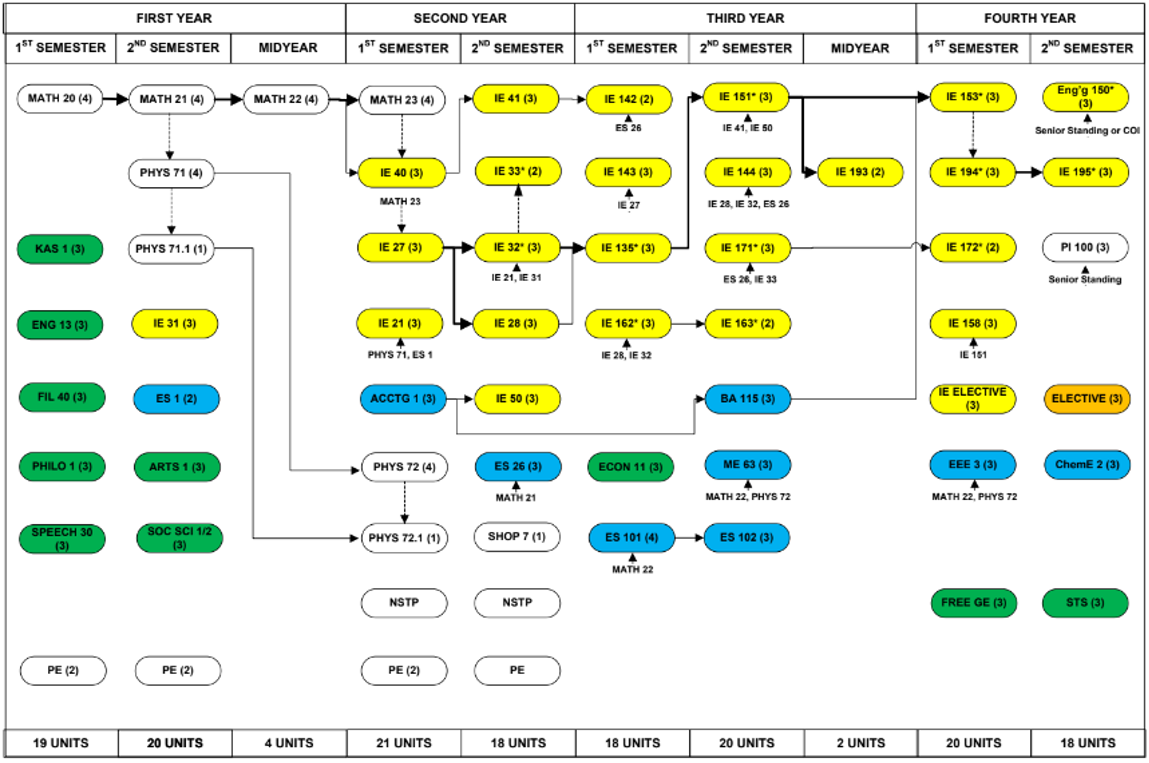

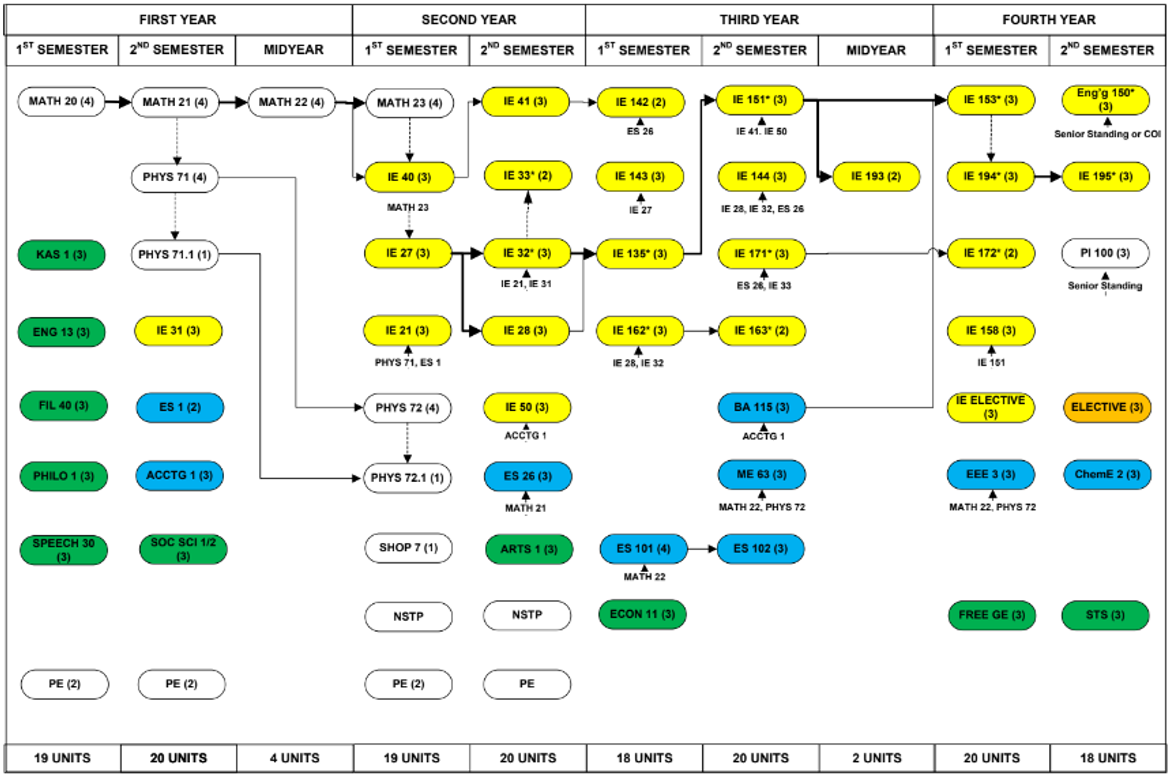

Undergraduate studies: bs industrial engineering, 2018 curriculum.

The objective of the Bachelor of Science in Industrial Engineering program is to provide a sound foundation in science and engineering in preparation for a professional Industrial Engineering career. The main tracks of the program are Production Systems, Operations Research, Human Factors and Ergonomics, and Information Systems.

FRESHMEN ENROLLMENT QUOTA

One hundred and ten (110) students.

STEM TRACK: 4 years, 156 units

NON-STEM TRACK: 4 years, 160 units

The image below displays the undergraduate IE curriculum in flowchart form.

NON-STEM TRACK (Option 1)

NON-STEM TRACK (Option 2)

BS Industrial Engineering Program of Study

General Education Courses, 30u total

- Eng 13 Writing as Thinking (3 u.)

- Fil 40 Wika, Kultura, at Lipunan (3 u.)

- Arts 1 Critical Perspective in the Arts (3 u.)

- Soc Sci 1 Foundations of Social Science / Soc Sci 2 Social, Economic and Political Thought (3 u.)

- STS 1 Science, Technology and Society (3 u.)

- Kas 1 Kasaysayan ng Pilipinas (3 u.)

- Philo 1 Philosophical Analysis (3 u.)

- Econ 11 Markets and the State (3 u.)

- Speech 30 Public Speaking and Persuasion (3 u.)

- Free GE (3 u.)

Foundation Courses, 34u total

- Math 20 Precalculus: Functions and their Graphs (4 u.) *NON-STEM TRACK only

- Math 21 Elementary Analysis I. Prereq: via High School Basic Calculus from the STEM or equivalent strand of K-12, Math 20 Validation Exam, or Math 20 (4 u.)

- Math 22 Elementary Analysis II. Prereq: Math 21 (4 u.)

- Math 23 Elementary Analysis III. Prereq: Math 22 (4 u.)

- Physics 71 Elementary Physics I. Coreq: Math 21 (4 u.)

- Physics 71.1 Elementary Physics I Laboratory. Coreq: Physics 71(1 u.)

- Physics 72 Elementary Physics II. Prereq. Physics 71 (4 u.)

- Physics 72.1 Elementary Physics II Laboratory. Prereq: Phys 71.1; Coreq: Phys 72 (1 u.)

- ES 1 Engineering Drawing. Prereq: None (2 u.)

- ES 101 Mechanics of Particles and Rigid Bodies. Prereq: Math 22 (4 u.)

- ES 102 Mechanics of Deformable Bodies. Prereq: ES 101 (3 u.)

- ES 26 Introduction to Computer Programming. Prereq: Math 21 (3 u.)

Core Courses, 67u total

- IE 21 Industrial Materials and Processes (3 u.)

- IE 27 Probability and Statistics for Industrial Engineering (3 u.)

- IE 28 Statistical Analysis for Industrial Engineering (3 u.)

- IE 31 Industrial Organization and Management (3 u.)

- IE 32 Work Study and Measurement (3 u.)

- IE 33 Systems and Procedures (2 u.)

- IE 40 Mathematical Methods for Industrial Engineering (3 u.)

- IE 41 Operations Research I (3 u.)

- IE 50 Engineering Economics for Industrial Engineering (3 u.)

- IE 135 Quality Control (3 u.)

- IE 142 Operations Research II (2 u.)

- IE 143 Stochastic Processes in Engineering (3 u.)

- IE 144 Systems Simulation (3 u.)

- IE 151 Production and Service Systems (3 u.)

- IE 153 Project Development and Management (3 u.)

- IE 158 Supply Chain Management for Industrial and Service Systems (3 u.)

- IE 162 Ergonomics I (3 u.)

- IE 163 Ergonomics II (2 u.)

- IE 171 Information Systems I (3 u.)

- IE 172 Information Systems II (2 u.)

- IE 193 Industrial Engineering Practicum (2 u.)

- IE 194 Industrial Engineering Capstone Project I (3 u.)

- IE 195 Industrial Engineering Capstone Project II (3 u.)

- Engg 150 Introduction to Technology Entrepreneurship (3 u.)

Cognate Courses, 16u total

- Acctg 1 Introduction to Financial Accounting. Prereq: None (3 u.)

- BA 115 Management Accounting. Prereq: BA 99.2/Acctg. 1 (3 u.)

- ChemE 2 Elementary Chemical Engineering. Prereq: None (3 u.)

- EEE 3 Elementary Electrical Engineering. Prereq: Math 54, Physics 72. (3 u.)

- ME 63 Thermodynamics. Prereq: Math 22, Physics 72 (3 u.)

- Shop 7 General Shop Practice (1 u.)

Mandated Course, 3u total

- PI 100, The Life & Works of Jose Rizal, (3 u.)

Elective Courses, 6u total

- IE Elective, (3 u.)

- Elective, (3 u.)

Physical Education and NSTP Courses, 14u total

Total number of units: 170

List of Approved IE Electives

- IE 122 Product Design and Development (Pre-req: IE 21. Co-req: Shop 7 ) (3 u.)

- IE 136 Manufacturing Systems (Pre-req: 4th year standing) (3 u.)

- IE 138 Manufacturing Management (Pre-req: 4th yr. standing ) (3 u.)

- IE 139 Reliability Engineering for Industrial Systems (Pre-req: IE 135; IE 143) (3 u.)

- IE 152 Manufacturing Planning and Design (Pre-req: IE 151. Co-req: IE 144) (3 u.)

- IE 161 Safety and Health Management (Pre-req: IE 160 or COI) (3 u.)

- IE 173 Data Analytics for Industrial Engineering (IE 171or equiv, IE 27or equiv) (3 u.)

- IE 174 Software Tools for Industrial Engineering (Pre-req: ES 26 or COI) (3 u.)

- IE 197 Special Topics (Pre-req: None) (3 u.)

- IE 198 Special Problems (Pre-req: Senior Standing) (3 u.)

List of Approved Non-IE Electives

- BA 151 Human Behavior in Organizations (Pre-req: BA 101 or COI) (3 u.)

- BA 152 Human Resource Management (Pre-req: BA 151 or COI) (3 u.)

- BA 170 Introduction to Marketing Management (Pre-req: BA 101) (3 u.)

- Econ 100.1 Introduction to Macroeconomic Theory and Policy (Pre-req: Math 11 or COI) (3 u.)

- Econ 100.2 Introduction to Microeconomic Theory and Policy (Pre-req: Math 11 or COI) (3 u.)

- EgyE 101 Introduction to Energy Engineering (Pre-req: Senior Standing) (3 u.)

- EnE 31 Technology and Environment (Pre-req: Prereq: 3rd yr. standing) (3 u.)

- MetE 143 Elements of Materials Science (Pre-req: Chem 16, Physics 72) (3 u.)

- Psych 101 General Psychology (3 u.)

* Other courses acceptable to the degree program sponsor

IE 21 Industrial Materials & Processes . Industrial materials & processes & their effects on production system decisions. Pre-requisites: Physics 71, ES 1. Credit: 3 units (3 hrs lecture).

IE 27 Probability and Statistics for Industrial Engineering . Applications of logic & probability in industrial engineering; random variables & their functions, descriptive statistics, discrete & continuous probability distributions & their applications. Sampling theory. Estimation & tests of hypotheses. Co-requisite: Math 23. Credit: 3 units (3 hrs lecture).

IE 28 Statistical Analysis for Industrial Engineering . Regression, correlation, analysis of variance, design of experiments & their applications in Industrial Engineering. Prerequisite: IE 27. Credit: 3 units (3 hrs lecture).

IE 31 Industrial Organization and Management . Basic features governing the organization, administration, & financing of industries. Relations between labor & management. Pre-requisite: None. Credit: 3 units (3 hrs lecture).

IE 32 Work Study and Measurement . Productivity concepts and techniques. Method study and work measurement. Work standardization and time standards. Wage payment. Indirect and expense labor standards. Training practices. Pre-requisites: IE 21, IE 27, IE 31. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 33 Systems & Procedures . System documentation & charting; introduction to information management & related ISO standards; system & procedures best practices. Corequisite: IE 32. Credit: 2 units (2 hrs lecture).

IE 40 Mathematical Methods for Industrial Engineering . Theory and applications of linear algebra, differential equations, and numerical methods for Industrial Engineering. Pre-requisite: Math 22. Co-requisite: Math 23. Credit: 3 units (3 hrs lecture).

IE 41 Operations Research I . Operations research methodology. Optimization models for linear systems. Linear programming. Duality and sensitivity analysis. Transportation, assignment and network models. Pre-requisite: IE 40. Credit: 3 units (3 hrs lecture).

IE 50 Engineering Economics for Industrial Engineering . Concepts and tools of economic analysis for decision-making. Interest and money-time relationships. Single and multiple project evaluation. After-tax economy studies. Decisions recognizing risk and uncertainty. Pre-requisite: Acctg 1. Credit: 3 units (3 hrs lecture).

IE 122 Product Design & Development . Framework for product life cycle design, integrated product & process design, development, prototyping & evaluation. Prerequisites: IE 21. Corequisite: Shop 7. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 135 Quality Control . Concept of quality, costs of quality, introduction to quality management systems, critical-to-quality parameters and specifications, control charting, process capability, gauge capability, acceptance sampling, quality improvement tools and introduction to Lean Six Sigma DMAIC methodology. Pre-requisites: IE 28, IE 32. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 136 Manufacturing Systems. Primary activities of a manufacturing firm. Manufacturing practices. Pre–requisite: 4th year standing. Credit: 3 units (3 hrs lecture).

IE 137 Quality Systems in Manufacturing . Concepts of quality. World-class quality programs & standards. Performance measurement & competitive priorities. Benchmarking. Corequisite: IE 136. Credit: 3 units (3 hrs lecture).

IE 138 Manufacturing Management. Organization & financial aspects of manufacturing . Manufacturing management principles. Pre-requisite: 4th year standing. Credit: 3 units (3 hrs lecture).

IE 139 Reliability Engineering for Industrial Systems . Basic concepts of reliability engineering. Reliability measurement system. Reliability analysis methods. Failure mode and effects analysis. Fault tree analysis. Risk analysis. Human reliability. Life testing, Reliability testing and evaluation. Design for reliability applications. Prerequisites: IE 135, IE 143. Credit: 3 units (3 hrs lecture).

IE 142 Operations Research II . Integer programming; dynamic programming; goal programming; game theory. Pre-requisites: ES 26, IE 41. Credit: 2 units (2 hrs lecture).

IE 143 Stochastic Processes in Engineering . Elements of stochastic processes; queuing theory & decision models; Markov chains, renewal theory & its applications to engineering problems. Pre-requisite: IE 27. Credit: 3 units (3 hrs lecture).

IE 144 Systems Simulation . Simulation of complex discrete event systems with applications in manufacturing & service organizations; random number & variate generation, input distribution modeling, statistical analysis of simulation output; case studies. Pre-requisites: ES 26, IE 28, IE 32. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 151 Production and Service Systems . Forecasting, Capacity Planning, Inventory Management, Aggregate Planning, Scheduling, Maintenance, Production Control. Prerequisites: IE 41, IE 50, IE 135. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 152 Manufacturing Planning and Design . Manufacturing process design. Location & layout of facilities. Materials flow systems. Materials handling. Storage & distribution. Pre-requisite: IE 151. Co-requisite: IE 144. Credit: 3 units (3 hrs lecture).

IE 153 Project Development and Management . Project identification and selection. Levels and stages of feasibility studies. Pre-feasibility analysis. Detailed project feasibility analysis. Overview, phases, concepts, risks, tools. Pre-requisites: BA 115, IE 151. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 155 Industrial Systems Design . Total systems design. Integration of sub-systems with concentration on optimal total systems implementation. A project & case study oriented course. Pre-requisites: IE 153, IE 154. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 158 Supply Chain Management for Industrial and Service Systems . An overview of concepts, processes, and best practices that are used in the management of supply chains. Supply chain management, procurement, customer relationship management, finance, information technologies, logistics activities and case studies. Pre-requisite: IE 151. Credit: 3 units (3 hrs lecture).

IE 160 Ergonomics . Origins & development of human factors & ergonomics; movement, cognitive & environmnetal factors in ergonomic workplace design & evaluation; tools & techniques of ergonomic risk assessment. Pre-requisite: IE 32/COI. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 161 Safety & Health Management . Hazard analysis techniques, human error analysis, safety standards & hazard communication; application of human factors & engineering practice in accident prevention & the reduction of health hazards on living & work environment. Pre-requisites: IE 160 or COI. Credit: 3 units (3 hrs lecture).

IE 162 Ergonomics I . Origins and development of human factors and ergonomics. Physical ergonomics. Design and evaluation; human factors research methods; movement factors and environmental factors in ergonomic workplace design and evaluation; tools and techniques of physical ergonomic risk assessment; physical workload. Pre-requisites: IE 32, IE 28. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 163 Ergonomics II . Introduction to cognitive ergonomics. Human error analysis. Human information processing; relation of cognitive limitations to design of effective displays and controls; human-computer interaction; fatigue and mental workload; social and organizational factors. Pre-requisites: IE 162. Credit: 2 units (1 hr lecture, 3 hrs laboratory).

IE 171 Information Systems I . Analysis and design of information systems. Drawing of data flow diagrams for information systems documentation. Structured Specification. Pre-requisite: ES 26, IE 33. Credit: 3 units (3 hrs lecture).

IE 172 Information Systems II . Implementation considerations in information systems design. Relational database systems. Pre-requisite: IE 171. Credit: 2 units (2 hrs lecture).

IE 173 Data Analytics for Industrial Engineering . Overview of data analytics and data mining. Design of end-to-end data mining processes, current methodologies and best practices used to transform raw data into useful information to support decision making. Pre-requisites: IE 171 Information Systems I or equivalent, IE 27 or equivalent. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 174 Software Tools for Industrial Engineering . Introduction to computer software packages for Industrial Engineering applications. Pre-requisites: ES 26, COI. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 193 Industrial Engineering Practicum . On-the-job training or industry internship. Prerequisite: IE 151. Credit: 2 units (100 hours field).

IE 194 Industrial Engineering Capstone Project I . Capstone project that will demonstrate the student’s research and design ability. IE undergraduate capstone project first course. Systems engineering design project proposal development. Problem identification and formulation. Co-requisites: IE 153. Credit: 3 units (2 hrs lecture, 3 hrs laboratory).

IE 195 Industrial Engineering Capstone Project II . IE undergraduate capstone project second course. Team-based systems engineering design project. Design solutions from a systems perspective. Pre-requisite: IE 194. Credit: 3 units (1 hr lecture, 6 hrs laboratory).

IE 197 Special Topics. Credit : 3 units (3 hrs lecture).

IE 198 Special Problems . Pre-requisite: Senior standing. Credit: 3 units (3 hrs lecture).

Engg 150 Introduction to Technology Entrepreneurship . Fundamentals of technology entrepreneurship, intellectual property, industry creation, and technology strategy. Opportunity recognition and evaluation. Business model development. Management of ventures. Pre-requisite: Senior standing or COI for non-IE students. Credit: 3 units (3 hrs lecture).

- Thesis Archive

- Gokongwei College of Engineering

- Academic Departments

Industrial and Systems Engineering

Undergraduate thesis archive.

This page lists all undergraduate theses in the Industrial Engineering Department (IE)

Capstone Design

Industrial Engineering 441 Capstone Design is a one-semester senior design course in which students engage in industry projects and practice industrial engineering under the guidance of an experienced Registered Professional Engineer, as well as engineers and managers from a sponsor company. The objective of these projects is to provide economic value to the company and a practical education to the students.

Project Description

Each project has four stages of design:

- Problem Definition

- Current State Analysis

- Future State Collaborative Design

- Final Project Validation/Delivery

Students perform in-depth quantitative analysis and design throughout the entire project. This includes extensive on-site and web/phone company involvement to ensure success. As a group, students are required to devote 60 hours per week for 14 weeks to the project.

We look for projects with an economic impact potential of over $100,000. Projects can be in workplace design, 5S/VSM and LEAN, time estimation and process engineering, factory layout, scheduling, inventory analysis, product/process quality analysis, process simulation, ergonomics, data mining and statistical analysis, manufacturability analysis, economic modeling, VB.NET/VBA/SQL programming and industrial automation CNC/RFID/BarCode/PLC Prog/Transducer selection.

Project Impacts

In Spring 2023, 16 projects were performed at 16 different companies. These companies were asked to provide their personal realistic estimate of the economic value of their student projects. The project values ranged from $25,000 to over $1.5 million with an average value of $526,000. Three projects exceeded $1 million in financial impact. Since these projects cost $5,000 per company, the average returns are substantial. Companies agreed to implement between 50% and 100% of student recommendations with an average implementation rate of 89%. Over 85% of our students have industry experience, and 25% have international experience, prior to working in Capstone. These engineers are mature, experienced and motivated, and receive extensive oversight.

Project Examples

Click here to view all of the videos

Mary Greeley Medical Center (MGMC)

This team worked on a project for Mary Greeley Medical Center (MGMC) to fix identified shortcomings in the emergency medical services department. The primary objective was to improve the quality of patient care provided by EMS through an improved logistical structure.

Contract Documents

- Non Disclosure Agreement

- Special Intellectual Property Agreement

- IMSE Sponsor Acknowledgement

- Capstone Design Brochure

- Capstone Syllabus

Examples of Past Projects - School of Industrial Engineering - Purdue University

Examples of Student Projects

Our students benefit from capstone projects to apply technical skills and hone soft skills. They help industrial sponsors solve real problems and make connections to jump start their careers. This is just a sampling of past projects.

Spring 2023 Capstone Projects

- Applied Fabricators - Preventative and Predictive Maintenance

- Applied Fabricators - Automated Sheet Stock Palletization

- Arcamed - Manufacturing Layout and Product Flow for Existing and New Space

- Copper Moon Coffee - Supply Chain Cost Optimization

- Clinton Prairie Schools - Food Service

- Clinton Prairie Schools - Transportation

- Descon - Facility Layout and Transition

- Dormakaba - Distribution Center Optimization

- HP - Visualizing Performance Metrics

- HP - Variation to Consumption Analysis

- Integra Life Sciences - Developing a Holistic Ergonomic Solution for Porcine Organ Tissue Extraction Process

- Inventus Power - Manufacturing Improvement Project

- Leadership Southern Indiana - Organizational Impact Dashboard

- MPI Corp - Optimization of Material Movement and Delivery

- MPI Corp - Optimization of the Value Stream for Washer Product Family

- Newbury Franklin Industrials - New Facility Layout

- Northstar Aerospace - Developing Data Driven Metrics & Visual Controls

- PepsiCo - Biodiesel Feasibility

- PepsiCo - Hydrogen Roadmap

- PepsiCo - MPG Optimization

- Phoenix USA RV - RV Parts Digital Library Design

- Photon Automation - Battery Submodule Assembly Line

- Purdue Dining - Refrigerator & Freezer Storage

- Purdue Disability Resource Center - Adaptive Educational Services - IUPUI

- Purdue Industrial Engineering - Manufacturing Lab Launch

- Purdue University North Central Nursing Clinics - Behavioral Health Intake Process Improvement

- Purdue University North Central Nursing Clinics - Improving Patient Flow at Delphi Clinic

- Purdue University North Central Nursing Clinics - Improving Patient Flow at Monon Clinic

- Telamon - Material Staging Flow Optimization

- Thinker Labs - SIBR/STTR Engagement Initiative Process & Tools

- Viewrail - Merge Matterport & Inventor Files

- Warrant Technologies: CMMI Migration V1.3 to V2.0

- Warsaw Chemical - Future State layout

- Modineer - Data Acquisition for Powder Coat Paint Line Decision Making

Fall 2022 Capstone Projects

- Amazon: Reducing Scrap on SLAM Machines

- Amazon: Reducing Downtime on SmartPac Machines

- Amazon: Maintenance Bench Test

- Decatur County and Decatur County Visitors Commission: Solar Eclipse Planning Logistics

- Diesel Forward: Wash Line and High-Pressure Blasting Automation

- Dynamic Metals: Preventative Maintenance

- Gem City Metals: Preventative Maintenance

- GNC: Pallet Put Away Structure Project

- HARPA: Noise Managing Headphones

- Hupp Aerospace/Defense: ERP Recommendation

- Indiana Tourism Association: Solar Eclipse Event Planning

- Northstar Aerospace: Manufacturing Visual Controls

- Penz Products: Insulated Foam Door Process Improvement

- Purdue Student Success Programs: Testing Center Co-Location

- Spencer County Visitors Bureau: Solar Eclipse Planning Logistics

- Tesla: Megapack Production Line Simulation

- Tramec Sloan: Fender Bracket Assembly

- Tramec Sloan: Manufacturing Line Process Improvement

- Tramec Sloan: Save-a-Load Bar

- Woodard, Emhardt, Henry, Reeves & Wagner: Billing Workflow Project

Learn how our students can help you.

Other Examples of Previous Projects

- Maximize (process & supply for) car seat plastics recycling

- Optimize vegetable seed production across multiple global locations

- Initiate a newly purchased hydroponic growth system, layout the area, and assess efficient and effective work flow design

- Optimize bed count with hospital forecasts at multiple Indiana Neonatal Intensive Care Unit (NICU) locations

- Reduce yield loss and environmental impact for our [product] production lines; process flow, identify loss points, quantify, prioritize losses, root cause, plan, implement, and estimated savings

- Design and recommend plant expansion layout: process mapping, flow analysis, simulation (Arena) of throughput and workstation design

- Design and implement a process control for food preparation and service to allergy sufferers in dining and catering services

- Aid data-driven decision making: evaluate and provide cost analysis of an IoT (Internet of Things) manufacturing monitoring platform

- Reduce clinician burnout and increase efficiency regarding electronic medical records activities

- Optimize transportation services to provide easy, safe, and supportive transportation for long term care clients' appointments

- Improve efficiency, effectiveness and accuracy of a sales forecasting model that includes a visualization tool, enabling quicker and more robust decision making

- Create an interactive chat bot for noise repair diagnostics

Student Project Partners

COMMENTS

Community-based Capstone Projects in Industrial Engineering. Anuj Mittal, Dave Adolfson, Matthew Matson, William Hiniker, Grace Patterson, and Peter Coleman. Industrial Engineering Technology ...

CE321 CIVIL ENGINEERING PROJECT 1 (CAPSTONE PROJECT) Welcome to this course, CE321 Civil Engineering Project! With the current situation, we are experiencing a "new normal" in the delivery of higher education in the country. Every student should watch the Student Virtual Orientation SY 2020-2021 that was aired via Facebook last September 11 ...

IE-CAPSTONE|IECapstoneProject IE_OBE_Rev.05/2020 INDUSTRIAL ENGINEERING PROGRAM COURSETITLE: IECAPSTONEPROJECT(IE-CAPSTONE) 2ndSemester,CurriculumYear2018-2019 HolyAngelUniversityVMs ... project Seatwork Assignment Writtenexam CaseStudy Critique Preparationoftheproposal. Christ-

Industrial Engineering brings together the various sciences concerned with technology, the ... IE Capstone Project 1 6 3 Engineering Values and Ethics 2 0 2 Methods of Research for IE 3 0 3 IE Practice with Comprehensive Examination 0 6 2 On-the Job- Training 4 Sub-Total 53 30 67 2. Electives

Industrial Engineering Students Making a Difference - Capstone Design Projects Impacting Adults with Disabilities Mayra I. Méndez-Piñero, PhD., Cristina Pomales-García, PhD., ... Capstone design project, adults with disabilities, design prototypes Introduction IE Capstone projects provide a meaningful design experience for senior students ...

IE 195 Industrial Engineering Capstone Project II. IE undergraduate capstone project second course. Team-based systems engineering design project. ... Room MH402, 4th Floor Melchor Hall, Magsaysay Avenue College of Engineering University of the Philippines 1101 Diliman, Quezon City. IE Department Chair's Office, Industrial Engineering ...

The principles of agile methodologies are: the continuous delivery of value to the client and/or user of the project, always prioritizing their needs; face-to-face interaction; empowering self-organized teams to work on the project; incremental and/or iterative learning that exploits the imagination (PMI 2017).

new processes take place. Taking advantage of these methodologies in the final Capstone project we expect our students will develop the specific outcomes which are needed by an Industrial Engineer to perform effectively in the Industrial Environment. Keywords: Student Outcomes, PPAP, APQP, Industrial Engineer, Improvement, Inventory, Profit. 1.

INDUSTRIAL, MANUFACTURING, & SYSTEMS ENGINEERING. CAPSTONE PROJECT /INTERNSHIP. SUMMARY. analysis, implementation and control phase by structuring our project in this manner we were successful. Within the company we had to present every week to our supervisor and that was another factor that maintained us organized and guided us in right path ...

Industrial and Systems Engineering; Thesis Archive; A strategic multiple-objective approach for customization of communication network technologies (2008) Thesis Archive ... 1004 Manila, Philippines. Tel. Nos.: (632) 524-4611 loc. 220 Telefax: (632) 524-0563 Email (Chair): ...

Industrial engineering is a branch of engineering which mainly focuses on the design, improvement, and installation of integrated systems of men, materials, equipment, and energy. The purpose of this study was to provide an overview of industrial engineering education in the Philippines. 91 schools that offered industrial engineering program ...

Department of Industrial and Manufacturing Systems Engineering

This page lists all undergraduate theses in the Industrial Engineering Department (IE) 2006. Identifier: Title: Adviser: TU13823: A facilities plan layout for the new campus site of TRACE college in fort bonifacio: ... 1004 Manila, Philippines. Tel. Nos.: (632) 524-4611 loc. 220 Telefax:

Teaching Engineering Design Through Project-Oriented Capstone Courses," Journal of Engineering Education , vol. 86, no. 1, pp. 17 - 28, 1997. [21] ABET, "Criteria for accrediting engineering ...

Capstone Design. Industrial Engineering 441 Capstone Design is a one-semester senior design course in which students engage in industry projects and practice industrial engineering under the guidance of an experienced Registered Professional Engineer, as well as engineers and managers from a sponsor company. The objective of these projects is ...

The Senior Capstone Design Course is part of the required coursework for the Bachelors in Science in Industrial Engineering.At the beginning of each semester (i.e. January and August), students enrolled in the Design Project Course (ININ 4079 - also known as the Capstone course), need to conduct a project co-hosted by an organization as part of the coursework.

The capstone projects were developed in randomly selected groups to develop a basic engineering proposal for an industrial process of local or national interest.

A Capstone Project Presented to the Faculty of the College of Informatics and Computing Sciences Batangas State University JPLPC-Malvar Malvar, Batangas. In Partial Fulfillment of the Requirements for the Degree Bachelor of Science in Information Technology Major in Business Analytics. DE OCAMPO, JEANDER R. LALAP, ASIS ALDRIN M.

Our students benefit from capstone projects to apply technical skills and hone soft skills. They help industrial sponsors solve real problems and make connections to jump start their careers. This is just a sampling of past projects. Spring 2023 Capstone Projects. Applied Fabricators - Preventative and Predictive Maintenance

In many cases the project includes the development of a product or a process, and its main aims are increasing students' learning output, causing them to experience a process of product ...

In this paper, five major shifts in engineering education are identified. During the engineering science revolution, curricula moved from hands-on practice to mathematical modeling and scientific ...