- Concrete block machine

- Brick making machine

- Hollow block machine

- Paving block machine

- OUR REFERENCES

Hollow Blocks Business Plan

The hollow blocks business plan has gained immense popularity in recent times, not just within our country but also across the globe, particularly among those aspiring to establish a profitable business in the construction industry. Presently, the market for building materials is witnessing significant growth and there are new types of concrete blocks that are more efficient and cost-effective.

In this article, we will present a comprehensive and profitable business plan for the production of hollow blocks. It is a complementary piece to the main article on hollow block machines , which highlights the technical and operational aspects of concrete hollow blocks and the machines used in their production. By referring to this plan, prospective private developers or entrepreneurs can effectively select the required equipment based on their specific requirements and goals.

When establishing a business in this field, entrepreneurs can expect to encounter minimal complexities, as the production technology is straightforward, and the finished product can easily obtain mandatory certifications. This advantage leads to reduced investments and reduces challenges associated with marketing and product promotion to a minimum. The concrete block machine serves as the primary equipment for manufacturing various building materials from concrete. These materials are hollow blocks, solid blocks, styrofoam concrete blocks, paving blocks, curbstones, and other decorative products.

The Hollow Blocks Business Plan Includes The Following Items

* Market analyses for the concrete products

* Business plan for the production process

* Purchasing concrete hollow blocks machine

* Production technology

* Calculation of profit of the enterprise

You especially need to answer these questions for this business. Why do you choose this particular line of activity? What is the advantage of a hollow blocks production business? Concrete hollow blocks are a fairly popular material in construction. Demand for it increases significantly during the construction season. This is due to the following factors:

- Affordability: Hollow blocks have a lower price compared to other construction materials, making them highly demanded for the construction of cost-effective country houses.

- Lightweight nature: Hollow blocks, depending on the raw materials used, are lighter than alternative construction materials. This advantage reduces the total weight of the building.

- Environmentally friendly: These special concrete hollow blocks are manufactured using only cement, sand, water, and various additive materials, without the inclusion of harmful chemicals. This ensures their environmental friendliness.

- Effective insulation: With low thermal conductivity, hollow blocks contribute to reducing heating costs in houses or rooms by approximately 20-30%. This eliminates the need for additional expenses on heat-insulating materials.

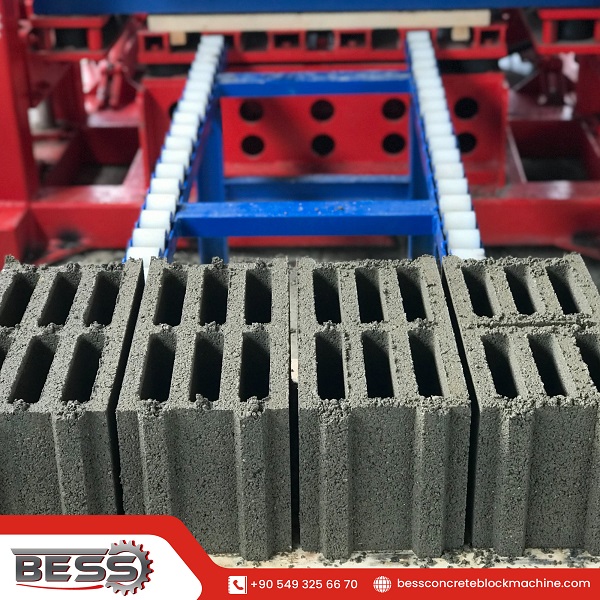

Block Making Machine Details

For producing good quality hollow blocks, you need to purchase any kind of high-quality concrete hollow blocks making machine.

What equipment will be needed for the production of hollow blocks :

- Hollow block making machine

- Concrete mixers

- Aggregate hopper for raw materials such as cement, sand, water, and additives

- Conveyor belts for transferring the materials into the mixer

- concrete block mold

- supplying raw materials, water, and cement

Production Process Of Concrete Hollow Blocks

The production process of concrete hollow blocks consists of three main stages:

- Mixture Preparation: In this initial stage, different raw materials are combined and mixed in a concrete mixer to create mortar. The mixer blends the ingredients thoroughly to ensure a homogeneous mixture.

- Block Production: The second stage involves the actual production of the blocks. This is achieved using either semi-automatic or automatic concrete hollow block machines. These machines are capable of efficiently shaping and forming the blocks according to the desired specifications.

- Curing and Storage: The final stage entails curing and storing the produced blocks. Once the concrete hollow blocks are ready, they are transferred to a designated area for the curing process. After curing, the blocks are then stored until they are ready to be transported or used in construction projects.

After thoroughly mixing the mixture, it is important to pour it into the machine and activate the vibration and pressure. This ensures that the mixture is evenly distributed within the molds. As the concrete shrinks, additional portions of the mixture should be added until the molds are completely filled. Once the concrete has sufficiently shrunk, the molds can be removed, leaving the finished blocks on the pallet or a suitable surface. At this stage, a new batch of mixture can be poured in the molds.

Drying the blocks needs to be given a separate time: the first 24 hours the blocks dry as they were left after the machine. During drying, they sometimes need to be moistened with water, like any concrete product. After a day, the blocks are turned on their side and dried for another 24 hours. After 2 days, they can be stacked on pallets. further details are provided in brick making machine article. also, the prices of the machine are included.

Curing the blocks requires a separate period of time. Initially, the blocks are left to dry for the first 24 hours in the same position as they were left after the molding process. During the curing period, it may be necessary to occasionally moisten the blocks with water, as is common for concrete products. After one day, the blocks are collected from the pallets and dried for an additional 24 hours. After a total of two days, the blocks can be stacked or sold. More detailed information can be found in the brick making machine article, including pricing details.

When developing a hollow blocks business plan, a crucial decision arises regarding the choice of the hollow blocks machine to purchase. In our company, we specialize in manufacturing and currently offer a range of machines designed to cater to aspiring entrepreneurs entering the hollow blocks business. Our machines provide different options, ensuring that customers can select the most suitable one for their needs.

All of our machines possess the capability to produce a wide variety of concrete stone products, including concrete hollow blocks, paving blocks, curbstones, and more. By simply changing the mold, it becomes possible to manufacture different types of concrete stone products. As demonstrated, one of our automatic concrete hollow blocks machines showcases remarkable versatility by being able to produce nearly all kinds of concrete stone products.

As you embark on your hollow blocks business journey, our company stands ready to provide the necessary machinery, allowing you to explore diverse product offerings and seize opportunities in the market.

If you need to produce double-layer paving blocks with color, you will need double-hopper block making machines. This machine is called a paving block machine and they are categorized differently. These machines are a little more expensive than normal machines. you can read further details in its own article paving block machine .

The Advantages Of The Hollow Block Making Machine

* We are using high-quality materials for the concrete block machine.

* According to your demand you can buy any kind of machine-like full or mini plant, for each machine which we are producing in our company.

* We have different automation for the machines, semi-automatic or automatic.

* All machines are capable to produce almost all kinds of concrete stone products just enough to change the mold.

* High productivity - the machines can produce concrete hollow blocks, paving blocks, curbstones, and others.

*For more videos you can visit our youtube channel Bess Machine En .

It is strongly advisable to invest in high-quality hollow block machines when entering the hollow blocks business. By acquiring a reliable and reputable machine, you can ensure the production of concrete stone products without any deformations or cracks. If you choose to purchase any type of hollow block machine, it grants you the flexibility to manufacture various kinds of concrete stone products.

For more comprehensive information regarding our machines, we encourage you to reach out to us. We are readily available to provide all the necessary details, including technical specifications and pricing information. Our website also serves as a valuable resource where you can explore the range of machines we offer. As you embark on your hollow blocks business plan, rest assured that we are committed to assisting both new and experienced customers in finding the most suitable hollow block machine. The hollow blocks business presents itself as an ideal venture for individuals seeking a profitable and fitting opportunity.

OTHER ARTICLES

Bess manufactures concrete block machines, paving block machines and molds.Bess is an organization of the Beyazli Group of Companies. Bess has started its international business in 2007 and developed in a short time because of the high quality machines it produces, reasonable price compared to the quality and efficient aftersales system.

OTHER LINKS

- CONCRETE PAVING MACHINES

- HOLLOW BLOCK MACHINES

- FINGER CAR MACHINES

- COMPACT MACHINES

- CONCRETE PLANTS

- CRUSHING AND SCREENING PLANTS

RECENT ARTICLES

- Hand carrier / Semi-automatic system

- Forklift / Automatic system

- Hollow Block Models

- Paving Block Models

- Hollow Floor Block (Asmolen) Mould Models

- Curbstone Models

- Grasscrete Mould Models

How to Start Hollow Bricks Manufacturing Business

Hollow bricks making business is a very good opportunity for aspiring individuals. If you want to set up a small-scale unit in the construction industry, then the hollow bricks project is ideal.

In addition, you can initiate the unit as a home-based. However, you will need to have a sufficient workplace. Also, a home-based business initiative allows you to operate with low-cost investment.

Table of Contents

What are Hollow Bricks & Uses

There are various types of bricks such as Common Burnt Clay Bricks, Sand Lime Bricks (Calcium Silicate Bricks), Concrete Bricks, Fly ash Clay Bricks, Fire Clay Bricks, and Hollow Bricks, the latest technology in the bricks segment.

Hollow bricks have an important role in the modern building industry. Hollow bricks are cost-effective. In addition, these bricks are a better alternative to burnt clay bricks by virtue of several reasons.

The list includes good durability, fire resistance, partial resistance to sound, thermal insulation, small dead load, and high speed of construction.

Generally, concrete hollow blocks come in a larger size than normal clay building bricks. Generally, it requires less mortar and you can expect faster construction.

Is Hollow Bricks Business Profitable?

Cement concrete hollow bricks are modern construction materials. Nowadays, these bricks hold an important position in all construction like residential, commercial, and industrial building constructions.

As construction activity is growing day by day, there is a good demand for cement concrete hollow bricks The demand for this product is always high in all cities and other urban centers.

Concrete hollow bricks are substitutes for conventional bricks and stones in building construction. They are lighter than bricks, easier to place, and also confer economics in foundation cost and consumption of cement.

In comparison to conventional bricks, they offer the advantages of uniform quality, faster speed of construction, lower labor involvement, and longer durability.

In view of these advantages, the applications of hollow concrete blocks are increasing very fast in construction activities.

Here are the Steps to Start Hollow Bricks Manufacturing Business

1. hollow bricks making business registration.

As a startup entrepreneur first, you need to decide the ownership pattern of your business. Register your business accordingly with ROC (Register Of Companies). Obtain Trade License from the local authority. Apply for Pan Card and open a current bank account.

You may register your business as SSI Unit also. If you want to avail of finance, then it is advisable to prepare a customized project report. In addition, apply for GST Registration . It is advisable to obtain a No Objection Certificate from the Pollution Control Board.

Related: Small Business Ideas For Small Towns

2. Raw Material Requirements

In hollow bricks manufacturing raw materials are cement, stone chips 0.5″, sand, and stone dust. Moreover, you can procure the raw material from nearby districts and from other states. Ordinary Portland cement is the cementing material used in cement concrete hollow blocks.

First of all, mix the cement, stone chips, sand, etc in a ratio of 1:6 or 1:12. This mixture is put in the vibrator machine. This is then poured into the desired size mold. After 24 hours of drying, put the blocks in the water tank for curing.

3. Manufacturing Process of Hollow Bricks

The process of curing continues for two to three weeks to give the blocks compression strength. The blocks are used in the construction process after drying.

Proportioning → Mixing → Compacting → Curing → Drying

a) Proportioning

The determination of suitable amounts of raw materials needed to produce concrete of desired quality under given conditions of mixing, placing, and curing is known as proportioning.

As per Indian Standard specifications, the combined aggregate content in the concrete mix used for making hollow blocks should not be more than 6 parts to 1 part by volume of Portland cement. If this ratio is taken in terms of weight basis this may average approximately 1:7

The objective of the thorough mixing of aggregates, cement, and water is to ensure that the cement-water paste completely covers the surface of the aggregates. All the raw materials including water are collected in a concrete mixer, which is rotated for about 1 ½ minutes.

c) Compacting

The purpose of compacting is to fill all air pockets with concrete as a whole without the movement of free water through the concrete. Excessive compaction would result in the formation of water pockets or layers with higher water content and poor quality of the product.

Hollow blocks removed from the mold are protected until they are sufficiently hardened to permit handling without damage. This may take about 24 hours in a shelter away from the sun and winds. The hollow blocks thus hardened are cured in a curing yard to permit complete moisturization for at least 21 days.

Concrete shrinks slightly with the loss of moisture. It is, therefore, essential that after curing is over, the blocks should be allowed to dry out gradually. You can dry it out normally in shade or you can use drying machines.

4. Hollow Bricks Making Machines

Broadly you can establish hollow bricks making projects in two ways. One is by setting up a semi-automatic plant with different machinery. Another one is by setting up fully automatic hollow brick-making machines.

For a semi-automatic plant, you will need to have types of machinery such as a Hydraulically operated concrete block-making machine with quadruple vibrators, a Concrete mixer, a platform electronic weighing scale, a Water dosing pump, Ram, molds, Curing beds, etc.

Fully automatic hollow brick machines are also available. With these types of machines, you can get 10000-12000 production output per hour. These are generally costly and different raw materials can be used to make different types of hollow bricks.

These types of machines have PLC automatic control systems, interactive user interfaces, control systems, security configuration logic control, production procedures, and fault diagnosis display. Automatic hollow bricks machine price starts from Rupees 3 Lakh onward.

6. Quality Specifications For Hollow Bricks

IS 2185 (Part 1): 2005 Indian Standard: Concrete Masonry Units – Specification (Part 1) Hollow and Solid Concrete Blocks (Third Revision) The above standard specifies requirements for these parameters: dimensions, grades of hollow blocks, blocks density, compression strength, water absorption, drying shrinkage, and moisture movement. However, the quality of the hollow bricks must be as per customer demand.

The Editorial Staff at NextWhatBusiness is a team of Business Consultants having years of experience in small and medium-scale businesses.

Press Releases

Success story: boyet’s hollowblocks manufacturing.

Janet Aluad Fuerte is a resident of Purok 5 Brgy. Antipolo, San Antonio, Zambales. Janet works as a cook at a carinderia in San Narciso, Zambales. In 2018, when her husband underwent a medical operation, she was forced to resign to take care of him.

Since both husband and wife cannot work, Mrs. Fuerte put up a stall in front of their house to serve “lutong-ulam” to cover their daily expenses. However, since the income derived from selling cooked food was not enough, the couple decided to venture into another business.

In August 2018, she started a hollow block manufacturing business also located at the vacant lot of her residence. It started with a small capital enough for buying materials for production and rent of equipment needed with two workers in the production.

Mrs. Fuerte made all her efforts to save all the money possible to sustain the business. Because of this, she was able to buy her own equipment for the production of the hollow blocks. In just a few months of testing the ground for her business, she decided to formalize the business by securing her business permit, environment compliance certification, and business name registration. In January 2020, she came to the Negosyo Center – San Antonio and registered her business under the name, “Boyet’s Hollowblocks Manufacturing” and likewise registered for the Barangay Micro Business Enterprise (BMBE).

Janet is a hard worker, a loving wife, and a mother to her husband and children, gumptious and resilient to weather the storms of her life.

By: BC Raymart C. Lacson / Negosyo Center – San Antonio

Share this page

Other Business Related Articles

Customer Service

Join us on social media.

Sign up for NEGOSYO CENTER updates

- BECOME A PARTNER

- SUBCRIBE NOW

- DIY Builder

Hollow Concrete Blocks: All You Need to Know!

- Pinoy Builders

- August 6, 2021

Shelter is one of the three basic needs of man along with food and clothing. The prehistoric man lived in caves, and later, he began constructing walls from the mud. In due course of time, many techniques for the masonry were developed and it became a structural part of the shelter. In early days, burnt brick masonry and stone masonry were popular. Now, with growing demand for construction, cheaper and faster techniques and materials are the need of the hour.

Concrete blocks are one such construction materials which help in achieving cheaper as well as faster construction than conventional bricks. The concrete blocks are available in two variations. 1) Solid concrete blocks and, 2) Hollow concrete blocks.In this article we are discussing both the varieties, yet, latter in more detail. The article deals with what hollow concrete blocks are, their pros and cons, properties and various types.

Concrete blocks are rectangular concrete masonry units either, solid (other than units used for bonding, such as a half-block) or hollow (open or closed cavity). Concrete blocks come in modular sizes and vary by country. Yet, their size and mass will be such that one can handle them easily. Moreover, to avoid confusion with slabs and panels, the height of the blocks should not exceed either its length or six times its width.

Two Major Types of Concrete Blocks or Concrete Masonry Unit

As mentioned above there are two major types of concrete blocks,

01. Solid Concrete Blocks

02. Hollow Concrete Blocks

01. solid concrete blocks.

Solid concrete blocks are made from aggregate , Portland cement and sand. These blocks have a solid material, not less than 75% of the total volume of the block calculated from the overall dimensions. Hence, they are heavy in weight. These blocks provide good stability to the structure. So, these blocks are used for a large work of masonry. They are used in the load-bearing walls as well as the non-load bearing walls. Solid blocks are available in large sizes as compared to the conventional bricks. Therefore, less time is required to construct concrete block masonry than brick masonry.

Also Read: Solid Concrete Blocks Vs AAC Blocks: How to Make the Right Choice

They are the standard sized rectangular hollow blocks made of cast concrete of high or low density. For high-density blocks, Portland cement and aggregate, usually sand and fine gravel are used as a raw material. For low density blocks, industrial wastes, such as fly ash or bottom ash are used as the primary raw materials and are often called cinder blocks /breeze blocks in different parts of the world.

As per the definition given in the ‘Indian Standard – IS 2185 (Part-1) 2005’ , hollow concrete blocks are having one or more large holes or cavities which either pass through the block (open cavity) or do not effectively pass through the block (closed cavity) and having the solid material between 50 and 75% of the total volume of the block calculated from the overall dimensions. These holes or cavities reduce the total cross-sectional area of the block and hence the weight of block structure as a whole.

Hollow concrete blocks are more commonly used in masonry construction. It accelerates the construction process, saves cement and steel and reduces the work expenses at the construction site. These blocks lower the natural weight of masonry constructions and improve the physical properties of walls, such as noise and thermal insulation. They also provide facilities for concealing electrical conduit , water and soil pipes.

Also Read: Benefits of Masonry in House Construction

Size of hollow concrete blocks.

Standard hollow concrete blocks are available in full size as well as half size. Full-sized blocks are rectangular and have two cores while half-sized blocks are cubical and contain one core.

According to the ‘ Research Designs & Standards Organization of Indian Railways ’ the nominal dimensions of concrete block are as follows:

- Length: 400, 500 or 600 mm

- Height: 200 or 100 mm

- Width: 50, 75, 100, 150, 200, 250 or 300 mm

Classification of Concrete Blocks

As per ‘Indian Standard – IS 2185 (Part-1) 2005’ classification of concrete blocks is given as below

01. Hollow (Open and Closed Cavity) Concrete Block

The hollow (open and closed cavity) concrete blocks are defined in followings grades:

- Grade-A type of blocks is used as load-bearing units and have a minimum block density of 1500 kg/m 3 . Grade-A type of blocks are manufactured for minimum average compressive strengths of 3.5, 4.5, 5.5, 7.0, 8, 5, 10.0, 12.5 and 15.0N/mm 2 at 28 days.

- Grade-B type of blocks is also used as load-bearing units and have a block density between 1100kg/m 3 and 1500kg/m 3 . Grade-B type of blocks are manufactured for minimum average compressive strengths of 3.5 and 5.0N/mm 2 at 28 days.

02. Solid Concrete Block

- The solid concrete blocks are used as load-bearing units and have a block density not less than 1800kg/m 3 . Grade-C type of blocks are manufactured for minimum average compressive strength of 4.0 and 5.0N/mm 2 .

Properties of Hollow Concrete Blocks

According to ‘ Building Materials & Technology Promotion Council – Ministry of Housing & Urban Poverty Alleviation, Government of India ’, physical properties of hollow concrete blocks are as below:

01. Moisture Movement : Not more than 0.09%

02. Water Absorption: Not more than 10%

03. Drying Shrinkage : Not more than 0.06%

04. Compressive Strength:

- For Grade A: 3.5 to 15.0 N/mm 2

- For Grade B: 3.5 and 5.0 N/mm 2

05. Density:

- For Grade A: 1500 kg/m 3

- For Grade-B: 1100 kg/m 3 to 1500 kg/m 3

Uses of Hollow Concrete Blocks

Hollow concrete blocks are used in all type of masonry construction such as,

- Exterior load-bearing walls

- Interior load-bearing walls

- Curtain walls

- Partition wall and panel walls

- Backing from brick, stone, and other facing

- Fireproofing over a structural member

- Fire-safe walls around stairwells, elevators

- Piers, column and retaining walls etc.

- Boundary fences

Advantages of Hollow Concrete Block Masonry

According to the research by ‘ Chaure, A. P., Shinde P. A. et al .’ followings are the advantages of hollow concrete blocks,

01. Hollow concrete block masonry is the easier and faster construction practice as compared to any other masonry practices.

02. Hollow concrete block masonry reduces the cost of construction labour and construction materials because the use of a larger size of concrete block reduces the number of joints in work.

03. Semi-skilled or unskilled labour can also work in this type of construction.

04. These concrete blocks need low maintenance and are durable.

05. They are eco-friendly materials as industrial wastes, such as fly ash or bottom ash are used as raw materials.

06. Reinforcing the hollow block masonry is possible as there is no additional formwork or any construction machinery required.

07. Hollow concrete block masonry is highly durable as the concrete is compacted by high pressure and vibration, which gives substantial strength to the block. Adequate curing increases the compressive strength of the blocks.

08. As the hollow concrete blocks are light in weight, they reduce the weight of the structure and hence light structural member or less percentage of steel is required for a given R.C.C building.

09. Presence of rough texture on concrete blocks provides good bonding between cement mortar and concrete blocks.

10. It is possible to construct a thin wall by using hollow blocks. Therefore, it helps to save space and increase the floor area or carpet area, i.e. carpet area efficiency is better.

11. In the hollow blocks, the voids or cores can be filled with steel bars and concrete for achieving high seismic resistance.

12. Hollow concrete blocks have good insulating properties against sound, heat and dampness.

13. These blocks have low water absorption than conventional bricks. If you want to know how to measure water absorption in bricks then read the water absorption test of bricks .

14. Hollow concrete block can safely resist the atmospheric action. This block doesn’t require protecting covering.

15. It has good fire resistance.

Disadvantages of Hollow Concrete Block

01. The cost of hollow concrete blocks is higher than the conventional bricks

02. The house built with hollow blocks without any interior reinforcement is likely to suffer damage during earthquakes.

Different Types of Hollow Concrete Blocks

Hollow concrete blocks are available in different types according to their shape, needs and design such as,

01. Concrete Stretcher Blocks

02. Lintel Blocks

03. Partition Concrete Blocks

04. Concrete Pillar Blocks

05. Corner Concrete Blocks

06. Jamb Concrete Blocks

07. Bullnose Concrete Block

08. Frogged Brick Blocks

Let us discuss each one of these types in detail.

01. Concrete Stretcher Blocks

Concrete stretcher blocks are most commonly used hollow concrete blocks in construction . These blocks are used to join the corner of masonry units. Stretcher blocks are placed with their length parallel to the face of the wall.

02. Lintel Blocks

Lintel blocks are also called channeled blocks or beam blocks; they are a U-shaped concrete masonry unit. These blocks have a deep groove along the length of the block. After placing the blocks, these grooves are filled with concrete along with reinforcement. Lintel blocks are used for the provision of the beam or lintel beam. Lintel beam is generally provided on the top of the portion of doors and windows, which transfers the load coming from the top.

Know More: What is Lintel? | Definition, Types & Purpose!

03. partition concrete blocks.

Partition concrete blocks are an ideal choice for the construction of partition walls . The hollow part of these blocks is divided into two or three components, and the height of the partition block is larger than its breadth.

04. Concrete Pillar Blocks

Concrete pillar blocks are also known as double corner block as both of its corners are plain. Thus, they are mostly used when two ends of the corner are visible. As the name suggests, , concrete pillar blocks are widely used in pillars or piers.

05. Concrete Corner Blocks

Concrete corner blocks are used at the corners of the masonry or at the end of window or at door opening. As shown in the image, one corner of the block is plain while the other is stretcher design. These blocks are arranged in such a manner that the plane end of block is exposed to the outside and another end is locked with the stretcher block.

06. Jamb Concrete Blocks

Jamb concrete blocks are used when there is an elaborated window opening in the wall. They are connected to stretcher and corner of the blocks. For the provision of double hung window, jamb concrete blocks are beneficial to provide space for the casing member of window.

07. Bullnose Concrete Blocks

Bullnose concrete blocks are similar to corner blocks in structure and function. But especially when we want rounded edges at the corner, these blocks are chosen.

08. Frogged Brick Blocks

Like the frogged brick, these frogged brick blocks having a frog on its top along with header and stretcher. This frog will help the blocks to hold mortar and develop a strong bond with the top lying block.

Summing up, hollow concrete blocks or hollow concrete masonry units are more beneficial building material than conventional bricks. They speed up the construction practice and reduces the overall construction time. The hollow blocks are also cheaper and are available in various sizes and shapes. With all these benefits, they are durable as well. Thus, they have become the preferred material for today’s buildings.

Originally Posted: https://gharpedia.com/blog/hollow-concrete-blocks-basic-information/

- hollow blocks

Do you want more information about this content?

Related posts.

NEWEST Flyover: DPWH Opens C-5-Quirino Flyover Extension in Las Piñas City

DPWH officially opened the C-5 Quirino Flyover Extension in Las Piñas City on Wednesday, April

Tiles & Trends: Design and Installation Tips for Stylish Tile Space

Tiles have long been a staple in home design, and have been completing the aesthetics

The Importance of Firewalls in the Philippine Construction Industry

Many areas in the Philippines are now more vulnerable to fire hazards and spread as

Leave a Comment

Recent posts.

FENCING 101: A Comprehensive Guide to Designing the Perfect Fence for Your Property

When it comes to securing and enhancing your property, few elements are as essential as

- News and Innovation

- Buhay Builder

- Safety Pulis

- Knowledge Builder

- Career Builder

- Green Builder

Subscribe for Monthly Updates

Sign up for exclusive monthly digests, upcoming offers, and early-bird slots for our latest webinars.

Copyright 2022. Pinoy Builders. Privacy Policy | Terms of Service

Subscribe for the latest update!

We Are An Experienced Company. Contact Us!

- Concrete Pump Machine

- Concrete Mixer With Pump

- Stationary Concrete Pump

- Small Concrete Pump Sale

- Pumpcrete For Sale

- Concrete Line Pump Truck

- Mobile Placing Boom

- Concrete Batching Plant

- Stationary Concrete Plant

- Mobile Concrete Batch Plant

- Ready Mix Concrete Plant

- Small Concrete Batch Plant

- Mini Concrete Batch Plant

- Concrete Mixer Truck

- Concrete Transit Mixer For Sale Philippines

- Concrete Agitator Truck

- Ready Mix Concrete Truck For Sale

- Mobile Concrete Mixer Truck For Sale

- Brick Making Machine

- Hollow Block Machine

- Automatic Brick Machine

- Concrete Block Machine

- Cement Block Machine

- Fly Ash Brick Machine

- Concrete Mixer Machine

- Twin Shaft Mixer

- Planetary Concrete Mixer

- Self Loading Mixer

- Diesel Concrete Mixer

- Crusher Machine

- Jaw Crusher Philippines

- Cone Crusher For Sale

- VSI Crusher

- Aggregate Crushing Plant

- Mobile Crushing Plant

- Asphalt Mixing Plant

- Asphalt Drum Mix Plant

- Mobile Asphalt Plant

- Small Portable Asphalt Plant

- Stationary Asphalt Mixing Plant

- Hot Mix Asphalt Plant

Hollow Block Making Machine Philippines

Hollow block making machine philippines is a hot sale product that is mainly used to produce various of bricks. With the development of the construction industry, there is a growing demand of bricks. So more and more customers plan to invest in a hollow block machine for sale philippines. As a professional brick making machine supplier in Philippines, Our Daswell Machinery is well-known. Moreover, many our customers are willing to recommend our company if their friends also need a hollow block maker for sale philippines.

Whether you want to buy a hollow block making machine for sale in the philippines for your own projects or selling the bricks, it is a wise decision for you. Of course, our hollow block maker equipment philippines also has many functions.

You can continue to browse our website to learn our products and our company. If you want to know more information about our hollow block maker in the philippines, contact us because we can provide you with more professional information.

Check out its models

Different customers have different requirements, so we provide various models of hydraulic hollow block machine philippines for our customers. Usually, its models include BMM4-26, BMM4-40B, BMM4-15, BMM5-15, BMM6-15, BMM8-15, BMM10-15 and BMM12-15.

The main difference among these models of automatic hollow block machine philippines is their production capacity. Therefore, if your construction project is not very big or your site is limited, you can select the small size of hollow block machine ph. On the contrary, if you have a great need for bricks, large size of brick machines are good for you.

In addition, our hollow block making machine in philippines has different control system for your reference, fully automatic type and semi automatic type. Different control system needs different number of operators. You can pick up a suitable model of hollow block making machine philippines depending on your real need. Or you can consult us and listen to some professional advice.

Where to buy hollow block machine in the Philippines

As we all know, choosing a right hollow block maker philippines is important. But where to buy a good hollow block machine in the Philippines. If you have a lot of experience about buying hollow block maker in philippines, maybe it is easy for you to choose a good product. If you are a new investor, you can read these tips.

engineers debug the machine

If you want to enjoy more service after buying the hollow block machine manila, we suggest you to choose these manufacturers that have office there. That is because when you meet some questions, these hollow block machine suppliers in philippines can arrive your sites and help you solve your problems, reducing your loss.

Like our Daswell Machinery, although we are a hollow block making equipment supplier from China, we set up our branch office and warehouse in Manila.

Daswell office in Philippines

Meanwhile, we send our salesman working there for a long period. We can deliver you spare parts in 12 hours if you need. Many of our customers speaks highly of our Daswell hollow block making equipment philippines because of its high quality and stable performance. We will be so glad if you are willing to visiting our branch office and warehouse .

Daswell warehouse in Philippines

How to buy the hollow block maker from our Daswell?

If you choose our company after knowing our strength, then we are very happy and glad to serve you. At the same time, we are confident that we can provide you with the right products and satisfactory prices.

If you get the information about our company online, you can browse our website and send us an inquiry. After our sales staff receives your message, they will get in touch with you as soon as possible according to the contact information you leave. And then discuss with you more detailed requuirements about the hollow block making machine that you want to buy. If you think our product and price are suitable, we will sign a contract and arrange the factory to start production. Eventually, you will receive our equipment before the appointed time.

If you are in Philippines and know our company through your friends or peers, you can learn our real stengths. Moreover, you can visit our customer's site and see the real situation of our machines working. Our sales staff in the Philippines can also visit your company or site if you need, plan your site and provide you with suitable solution.

Sometimes, our warehouse in the Philippines has a stock of brick machines, so that you can receive the machine soon after you place an order. Welcome to contact us and get more information!

Yes! I'm Interested!

Transport hollow block machines to Philippines

Philippines is one of our main market, and we always insist on serving our Philippines customers with the best attitude. At present, Daswell also has customers in various cities in the Philippines.

Up to now, we have exported many sets of hollow block making machine there. Most of our customers are glad to choose the BMM4-26 model. They think that this model of machine is stable working and small investment cost. Here are some transportation pictures for your reference.

Hollow block machine philippines price

Besides paying more attention to the quality, many customers are also concerned with the hollow block making product price philippines. Hollow block machine in philippines is a cost-effective product. So when you purchase it, you must consider its price. Choose our Daswell Machinery, we will offer you an affordable, favorable and reasonable hollow block maker price philippines. We know that there are many factors that affects the brick machine price. So our salesman will spare no efforts to help you minimize your initial cost.

Our company has our own factory, so we can provide our customers with our hollow block machine philippines directly. This will reduce the agency fee. Moreover, we have professional team to help you selecting suitable model of hollow block making machines, saving your purchase cost. At last, we also can teach you some useful regular maintenance methods. Right maintenance methods will reduce the failure rate of hollow block maker philippines and save your maintenance cost.

By doing this, you can reduce your cost and get a good hollow block making machine price in philippines. Waiting for your message!

If you have any questions or suggestions, please fill in the following form, Daswell will serve you wholeheartedly.

Best Ideas Ph

The Ultimate Guide to Hollow Block Sizes in the Philippines: Optimizing Construction Projects

admin_bestph

March 19, 2024

Hollow block size philippines refers to the standardized dimensions of hollow blocks used in the Philippines for construction purposes. These blocks are typically made from concrete or a mixture of concrete and aggregate, and feature hollow cavities that reduce their weight and improve insulation.

Hollow blocks are widely used in the Philippines due to their durability, ease of installation, and cost-effectiveness. They have played a significant role in the country’s construction industry since the 1960s, when they were first introduced as an alternative to traditional building materials like bricks. This transition to hollow blocks has facilitated faster and more efficient construction processes.

This article will delve into the various sizes of hollow blocks available in the Philippines, exploring their respective applications and advantages. We will also discuss the different factors to consider when selecting the appropriate hollow block sizes for construction projects.

Table of Contents

Hollow Block Size Philippines

Understanding the various dimensions of hollow block sizes used in the Philippines is crucial for ensuring structural integrity, efficient construction, and cost-effectiveness in building projects.

- Length: Typically ranges from 4 inches to 12 inches, with standard lengths being 6 inches and 8 inches.

- Width: Usually 4 inches or 6 inches, providing flexibility in wall thickness.

- Height: Standard height is 2 inches, allowing for faster construction and reduced labor costs.

- Thickness: Varies depending on the application, with common thicknesses being 4 inches, 6 inches, and 8 inches.

- Cavity Size: Hollow blocks feature cavities that reduce weight and improve insulation, with cavity sizes varying based on block dimensions.

- Density: Measured in kilograms per cubic meter, density affects the block’s strength and durability.

- Compressive Strength: Indicates the block’s ability to withstand compressive forces, expressed in megapascals (MPa).

- Water Absorption: Measures the block’s capacity to absorb water, influencing its durability and resistance to moisture.

- Fire Resistance: Hollow blocks provide varying degrees of fire resistance, depending on their composition and thickness.

- Sound Insulation: The hollow cavities in the blocks contribute to sound insulation, reducing noise transmission.

These key aspects of hollow block size philippines impact structural stability, construction efficiency, and overall building performance. Understanding these dimensions enables architects, engineers, and contractors to make informed decisions when selecting and using hollow blocks in construction projects.

The length of hollow blocks plays a crucial role in determining the overall dimensions and structural integrity of constructions. Standard lengths of 6 inches and 8 inches are commonly used in the Philippines due to their versatility and ease of handling. These standard lengths enable efficient stacking and alignment, reducing construction time and labor costs.

Longer hollow blocks, such as those measuring 10 inches or 12 inches in length, are often employed in the construction of load-bearing walls or large-scale structures. Their increased length provides greater stability and load-bearing capacity, making them suitable for high-rise buildings or structures subject to heavy loads.

Understanding the relationship between length and hollow block size philippines empowers architects, engineers, and contractors to select the appropriate block dimensions for specific construction projects. By considering factors such as structural requirements, load-bearing capacity, and cost-effectiveness, professionals can optimize building designs and ensure the longevity of structures.

The width of hollow blocks plays a significant role in determining the thickness of walls constructed using these blocks. The standard widths of 4 inches and 6 inches offer versatility in wall thickness, catering to diverse structural and design requirements.

- Structural Stability: Wider hollow blocks, such as those measuring 6 inches in width, provide enhanced structural stability to walls, making them suitable for load-bearing applications. They can effectively support heavier loads and resist lateral forces, ensuring the integrity of the structure.

- Space Optimization: Hollow blocks with a width of 4 inches are ideal for space-constrained areas or when constructing partition walls. Their slimmer profile allows for efficient utilization of space, without compromising on structural integrity.

- Insulation Properties: The width of hollow blocks influences their insulation capabilities. Wider blocks provide better thermal and acoustic insulation due to the increased air space within the cavities. This can contribute to energy efficiency and a more comfortable indoor environment.

- Cost-Effectiveness: The width of hollow blocks can impact the overall construction costs. Wider blocks typically require fewer units to cover the same area, potentially reducing material costs. However, wider blocks may also be more expensive per unit, so cost optimization requires careful consideration.

Understanding the implications of width in “hollow block size philippines” empowers professionals to make informed decisions when selecting the appropriate block dimensions for their construction projects. By considering factors such as structural requirements, space constraints, insulation needs, and cost implications, architects, engineers, and contractors can optimize building designs and ensure the efficiency and durability of structures.

The standardized height of 2 inches for hollow blocks in the Philippines plays a critical role in streamlining construction processes and minimizing labor costs. This uniform height enables efficient stacking and alignment of blocks, reducing the time and effort required to construct walls and structures. The optimized dimensions minimize the need for extensive cutting or adjustments, leading to faster construction timelines and reduced labor expenses.

Real-life examples of the impact of this standardized height can be observed in various construction projects across the Philippines. For instance, the construction of a residential building in Quezon City utilized hollow blocks with a height of 2 inches. The uniform height allowed for seamless stacking, reducing the overall construction time by approximately 15% compared to using blocks with varying heights. This efficiency translated into significant cost savings for the project.

Understanding the connection between “Height: Standard height is 2 inches, allowing for faster construction and reduced labor costs.” and “hollow block size philippines” empowers professionals to optimize construction practices and maximize efficiency. By leveraging the standardized height, architects, engineers, and contractors can streamline construction processes, reduce labor costs, and enhance project timelines. This understanding contributes to the overall productivity and cost-effectiveness of the construction industry in the Philippines.

In the context of “hollow block size philippines,” the thickness of hollow blocks is a crucial factor that influences their structural capabilities, insulation properties, and overall performance. The common thicknesses of 4 inches, 6 inches, and 8 inches cater to diverse construction requirements and present unique advantages.

- Structural Stability: Thicker hollow blocks, such as those measuring 8 inches in thickness, provide enhanced structural stability and load-bearing capacity. They are commonly used in the construction of load-bearing walls and multi-story buildings, where they can withstand significant compressive forces.

- Insulation: The thickness of hollow blocks directly impacts their insulation capabilities. Thicker blocks feature larger air cavities, which enhance thermal and acoustic insulation properties. This can contribute to energy efficiency, reduced noise transmission, and improved indoor comfort.

- Cost-Effectiveness: Thicker hollow blocks may require fewer units to achieve the desired wall thickness, potentially reducing material costs. However, they may also be more expensive per unit, necessitating careful cost-benefit analysis.

- Fire Resistance: The thickness of hollow blocks can influence their resistance to fire. Thicker blocks provide better fire protection due to the increased mass and air space, which helps to slow down the spread of flames and heat transfer.

Understanding the implications of thickness in “hollow block size philippines” empowers architects, engineers, and contractors to make informed decisions when selecting the appropriate block dimensions for their construction projects. By considering factors such as structural requirements, insulation needs, cost implications, and fire safety regulations, professionals can optimize building designs, ensure structural integrity, and enhance the overall performance of structures.

Cavity Size

In the context of “hollow block size philippines,” cavity size plays a crucial role in determining the overall weight and insulation properties of hollow blocks. The variation in cavity sizes, based on block dimensions, presents unique advantages and considerations.

- Weight Reduction: Hollow blocks are designed with cavities to reduce their weight compared to solid blocks. The larger the cavities, the lighter the blocks become, making them easier to handle, transport, and install.

- Thermal Insulation: The air trapped within the cavities of hollow blocks acts as a natural insulator, reducing heat transfer. Larger cavities enhance this insulation property, contributing to energy efficiency and improved indoor comfort.

- Acoustic Insulation: The cavities in hollow blocks also provide acoustic insulation, dampening sound transmission. Larger cavities are more effective in absorbing and dissipating sound waves, creating a quieter indoor environment.

- Structural Implications: While cavities reduce weight and enhance insulation, they can also affect the structural strength of hollow blocks. Blocks with larger cavities may have reduced compressive strength compared to those with smaller cavities. Therefore, the selection of cavity size should consider both insulation needs and structural requirements.

Understanding the implications of cavity size in “hollow block size philippines” empowers professionals to make informed decisions when selecting hollow blocks for their construction projects. By considering factors such as weight reduction, insulation requirements, acoustic performance, and structural integrity, architects, engineers, and contractors can optimize building designs and ensure the overall efficiency and performance of structures.

Within the context of “hollow block size philippines,” density plays a crucial role in determining the strength and durability of hollow blocks. Measured in kilograms per cubic meter, density reflects the mass of the block relative to its volume.

- Compressive Strength: Higher density hollow blocks exhibit greater compressive strength, enabling them to withstand higher loads without crushing or breaking. This is particularly important in load-bearing applications, such as the construction of walls and columns.

- Durability: Denser hollow blocks are generally more durable and resistant to wear and tear. They can better withstand harsh environmental conditions, such as extreme temperatures, moisture, and chemical exposure, prolonging the lifespan of structures.

- Fire Resistance: The higher density of hollow blocks can contribute to improved fire resistance. Denser blocks have a lower porosity, which reduces the penetration of heat and flames, enhancing the overall fire safety of buildings.

- Acoustic Insulation: While the cavities in hollow blocks provide some acoustic insulation, denser blocks can further enhance sound absorption. The increased mass helps to dampen sound waves, reducing noise transmission and creating a quieterenvironment.

Understanding the implications of density in “hollow block size philippines” empowers professionals to select appropriate blocks for specific construction applications. By considering factors such as structural requirements, durability needs, fire safety regulations, and acoustic performance, architects, engineers, and contractors can optimize building designs and ensure the longevity and performance of structures.

Compressive Strength

In the context of “hollow block size philippines,” compressive strength plays a critical role in ensuring the structural integrity and longevity of buildings. Measured in megapascals (MPa), compressive strength quantifies the block’s ability to resist compression or crushing forces.

- Load-Bearing Capacity: Compressive strength directly influences the load-bearing capacity of hollow blocks, determining their suitability for use in load-bearing walls, columns, and other structural elements.

- Structural Stability: Hollow blocks with higher compressive strength contribute to the overall stability of structures, reducing the risk of collapse or failure under heavy loads or seismic activity.

- Durability: Compressive strength is an indicator of the block’s resistance to wear and tear. Blocks with higher compressive strength are more durable and can withstand harsh environmental conditions and aging effects.

- Safety and Reliability: Ensuring adequate compressive strength in hollow blocks is essential for public safety and structural reliability, preventing potential failures and safeguarding the occupants of buildings.

Understanding the implications of compressive strength in “hollow block size philippines” empowers architects, engineers, and contractors to make informed decisions when selecting and using hollow blocks in construction projects. By considering factors such as structural requirements, load-bearing capacity, durability, and safety regulations, professionals can optimize building designs, enhance structural performance, and ensure the longevity and reliability of structures.

Water Absorption

Water absorption is a crucial factor to consider when selecting hollow blocks for construction projects in the Philippines. It directly influences the block’s durability, longevity, and resistance to moisture, making it a critical aspect of “hollow block size philippines.”

- Porosity: Hollow blocks exhibit varying degrees of porosity, which affects their water absorption capacity. Blocks with higher porosity tend to absorb more water, potentially compromising their strength and durability.

- Exposure to Moisture: Buildings in areas with high humidity or frequent rainfall require hollow blocks with low water absorption rates to prevent moisture penetration and structural damage. Moisture absorption can lead to mold growth, efflorescence, and deterioration of the blocks over time.

- Freeze-Thaw Resistance: In regions experiencing freezing temperatures, water absorption becomes particularly important. Blocks with high water absorption can freeze and expand, causing cracks and structural damage. Low water absorption is essential for freeze-thaw resistance.

- Durability and Lifespan: Hollow blocks with low water absorption are more resistant to weathering and aging, extending their lifespan and reducing maintenance costs. They are less susceptible to erosion, spalling, and other forms of deterioration caused by moisture.

Understanding the implications of water absorption in “hollow block size philippines” allows architects, engineers, and contractors to make informed decisions when selecting hollow blocks for specific construction applications. By considering factors such as environmental conditions, moisture exposure, and structural requirements, professionals can enhance the durability, longevity, and overall performance of buildings constructed using hollow blocks.

Fire Resistance

Within the context of “hollow block size philippines,” fire resistance emerges as a critical factor influencing the safety and structural integrity of buildings. Hollow blocks exhibit varying degrees of fire resistance based on their composition and thickness, making it an essential aspect to consider in construction projects.

- Composition: The type of materials used in the production of hollow blocks directly affects their fire resistance. Blocks made with lightweight aggregates, such as pumice or expanded clay, offer superior fire resistance compared to those made with denser materials like sand or gravel.

- Thickness: Thicker hollow blocks generally provide better fire resistance than thinner ones. The increased thickness creates a larger mass, which absorbs and dissipates heat more effectively, delaying the spread of flames and protecting the structural integrity of the building.

- Cavity Design: The design and arrangement of cavities within hollow blocks can impact their fire resistance. Blocks with smaller, enclosed cavities tend to perform better in fire conditions, as they restrict the flow of hot gases and oxygen, slowing down the combustion process.

- Additives and Coatings: Manufacturers may incorporate fire-resistant additives or coatings into hollow blocks to enhance their performance in fire situations. These additives can react with heat to form a protective layer or release non-flammable gases, further increasing the block’s ability to withstand fire.

Understanding the implications of fire resistance in “hollow block size philippines” empowers architects, engineers, and contractors to select and utilize hollow blocks effectively in construction projects. By considering factors such as building codes, fire safety regulations, and the specific fire hazards associated with the intended use of the structure, professionals can design and construct buildings that meet the highest standards of fire safety and protect occupants from the devastating effects of fire.

Sound Insulation

Hollow blocks are acknowledged for their sound insulation properties, a critical consideration in “hollow block size philippines.” These blocks effectively mitigate noise transmission due to their unique structural design.

- Cavity Structure: Hollow blocks feature cavities or air pockets within their structure. These cavities act as sound barriers, absorbing and dissipating sound waves, thereby reducing noise transfer through walls.

- Porosity: The porous nature of hollow blocks further contributes to their sound insulation capabilities. Sound waves are effectively absorbed within the pores, minimizing their transmission.

- Mass: The mass of hollow blocks plays a role in sound insulation. Thicker blocks with higher mass provide better soundproofing compared to thinner ones, as they impede sound waves with greater efficiency.

- Frequency Absorption: Hollow blocks are particularly effective at absorbing mid- to high-frequency sounds, such as human speech and traffic noise. This makes them suitable for use in residential and commercial buildings where noise reduction is a priority.

Understanding the sound insulation properties of hollow blocks empowers architects and engineers to design and construct buildings that provide a quieter and more comfortable living or working environment. By incorporating hollow blocks with appropriate dimensions and configurations, professionals can effectively reduce noise pollution, enhance privacy, and contribute to the overall well-being of occupants.

Frequently Asked Questions (FAQs) on Hollow Block Size Philippines

This FAQ section aims to address common queries and clarify various aspects of “hollow block size philippines” to assist architects, engineers, contractors, and homeowners in making informed decisions during construction projects.

Question 1: What factors influence the selection of hollow block size?

Answer: The selection of hollow block size is influenced by multiple factors, including structural requirements, wall thickness, insulation needs, fire resistance, and cost considerations. Each factor should be carefully evaluated to ensure optimal performance and cost-effectiveness.

Question 2: How does block length impact construction?

Answer: The length of hollow blocks affects the overall dimensions and structural stability of constructions. Standard lengths of 6 inches and 8 inches are commonly used for their versatility and ease of handling, while longer blocks may be employed for load-bearing walls or large-scale structures.

Question 3: What is the significance of block width?

Answer: The width of hollow blocks determines the thickness of the walls constructed using these blocks. Wider blocks provide enhanced structural stability and are suitable for load-bearing applications, while narrower blocks are ideal for space-constrained areas or partition walls.

Question 4: How does block thickness affect insulation properties?

Answer: Thicker hollow blocks feature larger air cavities, which enhance thermal and acoustic insulation capabilities. This contributes to energy efficiency, reduced noise transmission, and improved indoor comfort.

Question 5: What is the role of cavity size in hollow blocks?

Answer: Cavity size influences the weight and insulation properties of hollow blocks. Larger cavities reduce block weight, facilitating handling and transportation, while also enhancing thermal and acoustic insulation.

Question 6: How does density impact block strength and durability?

Answer: Density is a crucial factor affecting the strength and durability of hollow blocks. Denser blocks exhibit higher compressive strength, enabling them to withstand heavier loads and resist wear and tear, extending their lifespan and reliability.

In summary, understanding the implications of various hollow block size parameters is essential for optimizing construction practices and ensuring the structural integrity, efficiency, and longevity of buildings in the Philippines.

Moving forward, the next section will delve into the advantages and disadvantages of using hollow blocks in construction, providing valuable insights for informed decision-making.

This section provides practical tips to guide architects, engineers, contractors, and homeowners in selecting and using hollow blocks effectively in construction projects in the Philippines.

Tip 1: Determine Structural Requirements: Assess the load-bearing needs and structural demands of the construction to determine the appropriate block size and compressive strength.

Tip 2: Consider Wall Thickness: Choose block widths that align with the desired wall thickness, balancing structural stability with space optimization.

Tip 3: Optimize Insulation Properties: Select hollow blocks with larger cavities to enhance thermal and acoustic insulation, improving energy efficiency and indoor comfort.

Tip 4: Ensure Fire Resistance: Choose hollow blocks with appropriate fire resistance ratings based on building codes and the intended use of the structure.

Tip 5: Address Water Absorption: Opt for blocks with low water absorption rates to enhance durability and resistance to moisture damage, especially in humid environments.

Tip 6: Evaluate Sound Insulation: Consider the sound insulation properties of hollow blocks, particularly in noise-sensitive areas such as residential buildings or offices.

Tip 7: Consider Cost Implications: Compare the costs of different hollow block sizes and consider factors such as material availability and transportation expenses.

Tip 8: Seek Professional Advice: Consult with architects, engineers, or industry experts to obtain personalized recommendations and ensure optimal selection and use of hollow blocks.

By following these practical tips, professionals and homeowners can make informed decisions regarding hollow block size philippines, leading to durable, efficient, and cost-effective constructions.

Moving forward, the concluding section will summarize the key advantages of using hollow blocks and emphasize their role in sustainable and resilient construction practices.

This comprehensive exploration of “hollow block size philippines” has illuminated the multifaceted considerations involved in selecting and utilizing hollow blocks in construction projects. The article delved into the impact of length, width, height, thickness, cavity size, density, water absorption, fire resistance, and sound insulation on the overall performance and suitability of hollow blocks.

Key takeaways include the importance of matching block size to structural requirements, optimizing insulation properties for energy efficiency and comfort, ensuring fire resistance for safety, and considering water absorption and sound insulation for durability and occupant well-being. By carefully evaluating these factors, architects, engineers, contractors, and homeowners can make informed decisions that contribute to sustainable and resilient constructions.

Images References :

Leave a comment cancel reply.

Save my name, email, and website in this browser for the next time I comment.

most recent

Unveiling the Sacred and Secular: Discover the Panagbenga Festival's Unique Blend

Experience the Bacolod MassKara Festival: A Journey into Filipino Culture and Heritage

Unveiling the Allure of Masskara Festival through Captivating Pictures

Discover the heart of tuna fishing and filipino culture at the gensan tuna festival.

Unveiling the Rich History of the Bangus Festival: Discoveries and Insights

Unveiling the Secrets of Masskara Festival Design: A Journey of Discovery and Delight

Business Hours: Monday to Friday: 9:00 AM - 5:00 PM Saturday: 10:00 AM - 2:00 PM Closed on Sundays and Public Holidays

Office Address: Best Ideas PH [Your Business Address Here] [City, Zip Code] Philippines

© 2024 INFO

Home » Hollow Blocks Price List and Buying Guide

Hollow Blocks Price List and Buying Guide

Hollow concrete blocks are often used to build walls, fences, and other structures because they are lighter and cheaper in price than solid blocks.

Hollow blocks cost between ₱12.00 and ₱16.00 each for regular blocks and between ₱21.00 and ₱35.00 each for 450 PSI blocks.

In this article we will tell you everything you need to know about hollow blocks price in Philippines.

Including what they are used for, how big they are, and what you need to know before you buy them.

Table of Contents

What Is Hollow Blocks

Hollow blocks are rectangular blocks with holes in them. They are also called concrete hollow blocks (CHB) or breeze blocks.

They are made by mixing Portland cement , sand, and other materials.

Because they are easy to move, carry, and put together, these blocks are often used in building.

They can be painted or treated with different colors and textures to make different designs.

Since hollow blocks are bigger than regular bricks, they can be put together faster.

There are standard sizes for CHB, so building projects are always the same.

Uses of Hollow Blocks

Hollow blocks are used in building for many different reasons, such as:

- Load-bearing walls: Hollow blocks provide structural support for both the outside and inside of walls. They can hold big weights and withstand bad weather.

- Facades and curtain walls: Hollow blocks can be used to make artistic facades or protective layers on top of structural walls. This makes the building look better and keeps it warmer.

- Prefabricated panels: Hollow blocks can be put together to make prefabricated panels, which make building faster and more efficient and reduce the need for more concrete and steel.

- Partition walls: Hollow blocks are often used to split different rooms or areas inside a building. This gives people more privacy, reduces noise, and saves energy.

- Fire-safe walls: Because hollow blocks don’t catch fire, they can be used to build walls around lifts, stairwells, and other places where fire safety is very important.

- Boundary fences: Hollow blocks mark the edges of lands and give them security, privacy, and a nice look.

- Retaining walls: Hollow blocks can be used to build retaining walls, which hold back dirt or water to stop erosion and make terraces or other features for landscaping.

Overall, hollow blocks are versatile, strong, and long-lasting, which makes them an important part of many masonry building projects.

Type of Hollow Blocks

There are different types of hollow blocks available in the market, such as:

Base Concrete Hollow Block

This is the most popular type of hollow block. It is strong, doesn’t shrink or break, and lasts a long time. It is the same size and shape all over and has a smooth surface.

Rough Surface Hollow Block

This type of hollow block looks rough or crushed, which gives a wall or fence structure and character. It goes well with patterns that are rustic or natural.

Colored Concrete Hollow Blocks

This type of hollow block has a colored coating on one or both sides that makes it more beautiful. It works great for walls and building decorations.

Decorative Hollow block

This type of hollow block has a pattern or design on one or both sides that makes a wall or fence look more interesting and stylish. It works well for patterns that are modern or artistic.

Hollow Block Size

Hollow block size Philippines vary but there are standard sizes that are commonly used in the country. These are:

- CHB 4: 40 cm (length) x 20 cm (width) x 4 inches (thickness)

- CHB 5: 40 cm (length) x 20 cm (width) x 5 inches (thickness)

- CHB 6: 40 cm (length) x 20 cm (width) x 6 inches (thickness)

- CHB 8: 40 cm (length) x 20 cm (width) x 8 inches (thickness)

The size of the hollow block affects its strength, weight, cost, and appearance. Generally, larger blocks are stronger but heavier and more expensive than smaller ones. Smaller blocks are lighter but weaker and cheaper than larger ones.

Hollow Block Price List in Philippines

The price of hollow blocks depends on several factors, such as type, size, quality, location of the supplier and market condition.

Beside that, the price of a concrete hollow block machine ranges from around ₱30,000 for a manual, mobile type to around ₱10,000,000 for an industrial, automatic type.

Hollow Block Advantages and Disadvantages

Hollow blocks have many benefits, such as:

- They are lightweight and easy to move, install, and handle.

- They don’t let fire or sound through, keep heat in, and can’t be broken.

- They can stand up to earthquakes, last a long time, don’t cause waste, and use energy and resources efficiently.

- They are versatile and can be used for many different uses and designs.

- They are cheap and can save time and money in building.

But hollow blocks also have some drawbacks, such as:

- They are not as strong as solid blocks and may need strengthening or extra support.

- They can get cracks or other damage from wetness or temperature changes.

- They may be different in quality or consistency based on who makes or sells them.

- They may not be easy to find or get to in some areas or places.

Thing You Should Know about Hollow Block

Before buying hollow blocks, you should know some important things, such as:

- Why do people in the Philippines use hollow blocks? In the Philippines, hollow blocks are used because they are strong, last a long time, and are inexpensive.

- What is an empty block called by another name? A hollow block is also called a hollow brick, breeze block, or concrete hollow block (CHB).

- Are concrete blocks that are hollow strong? Solid concrete blocks are stronger than hollow ones, but not as strong. Depending on the weight, they may need to be made stronger.

- Which is better: solid or hollow blocks? Hollow blocks are better for building because they are lighter, better at insulating, and use less energy. Solid blocks are more durable and also look better.

- Can the base be made with hollow blocks? With reinforcement, hollow blocks can be used for the base, but solid blocks are better for strength and stability.

Phenolic Board Price List and Buying Guide

Cement Price List and Buying Guide

Leave a comment cancel reply.

Save my name, email, and website in this browser for the next time I comment.

Pinas Hardware

Your Gold Standard Source for Philippines Hardware Price Lists

Hollow Blocks Price Philippines

Hollow Blocks or hollow cements are rectangular-shaped concrete blocks with hollows made with the use of concrete block-making machines. These blocks have hollow cores within their structure, which significantly reduces their weight while still maintaining strength. The use of hollow blocks is very common in construction projects for applications such as building walls, partitions, and other structural elements due to their versatility and cost-effectiveness when compared to pure concrete blocks.

Hollow Blocks Prices

The prices of hollow blocks can vary based on factors such as the materials used and the size of each block. Typically, the average cost per block falls within the range of ₱20.00 to ₱50.00. These price variations provide flexibility for customers to choose blocks that best suit their construction needs while considering budget constraints.

Advantages of Hollow Blocks

Reduced Weight – The hollow core design of hollow blocks reduces their overall weight which makes them easier to handle, transport, and install compared to solid blocks or traditional bricks.

Cost-Effective – Hollow Blocks are often considered cost-effective as they provide greater coverage with less material used than pure concretes which can result in larger cost savings in construction projects.

Versatility – Hollow Blocks are versatile and can be used for various construction applications, including load-bearing walls, non-load-bearing walls, partitions, and more.

Strength and Durability – Hollow Blocks are mostly used to provide structural support and stability which makes them suitable for different types of projects such as

Reduced Material Consumption – The hollow design allows for the efficient use of materials, reducing the amount of concrete required compared to solid blocks.

Disadvantages of Hollow Blocks

Limited Load-Bearing Capacity – While hollow blocks can provide structural strength, their load-bearing capacity is limited compared to solid blocks in most applications.

Moisture Absorption – The hollow cores in the blocks can also absorb moisture, particularly if it is not properly sealed or protected which could affect the overall durability of the blocks in certain conditions.

Surface Finish – The surface texture of hollow blocks may not always have the same aesthetic appeal as some other materials. Additional finishing techniques are needed for decorative purposes.

Transportation – The lightweight nature of hollow blocks can be an advantage, but it may also lead to challenges during transportation, as it makes them prone to breaking and cracking.

Video of Hollow Blocks

What are hollow blocks used for?

Hollow blocks as its name suggests are blocks of concrete with hollows in their cross-section area used for building boundary fences and other structures.

What is the standard size of hollow blocks?

There are different sizes of hollow blocks, but the most common sizes are 4 inches, 5 inches, 6 inches, and 8 inches.

What is another name for hollow block?

The most common alternative names for hollow blocks are hollow cement blocks and hollow concrete blocks.

What is CHB in construction?

CHB in construction is the term for masonry which is the process of building structures with individual units like brick, stone, concrete, and block.

What is the alternative to hollow blocks?

The most used alternative for hollow blocks in the Philippines is the concrete precast wall form block which is also a patented Filipino invention.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Hollow Block Making Business Plan Philippines

(33 products available)

fully automatic brick and block making business plan

Best Sale Kerb Curbstone brick making machinery Qt4-24 Hollow Concrete Blocks Making Business Plan

concrete block manufacturing business plan

Concrete Block Cement Brick Making Machine Price/ Paver Brick Machinery / Hollow Concrete blocks Making Business Plan

QTJ4-25 new business ideas machine block and brick making machine for small business plans

QTJ4-40 Concrete blocks bricks making business plan

Concrete block manufacturing business plan QT8-15 automatic concrete hollow block molder machine production line

About products and suppliers

Whether you need to work with concrete blocks, hollow blocks, or paving slabs, finding the right brick making machinery is essential. At Alibaba, you'll find a wide range of tools to get the job done, with models to use on construction sites and brick makers for factories. Explore specialist brick making equipment and toggle different features to find exactly what's required. Wherever you look, you'll see wholesale prices to drive down construction costs. So if you need a new hollow block making business plan philippines there's no better place to look.

Every style of brick requires specialist machinery, and every type of brick making machinery can be found at Alibaba. For instance, if you're intending to build a shell from hollow bricks, there's no shortage of machinery to think about. Pick a model that creates the shape you need with enough production capacity to suit your project. Alternatively, there are clay brick presses to create solid blocks, as well as machines designed to produce flat paving stones for drives and pathways. Whether you need interlocking or hollow bricks, there's a solution here. Finding a new hollow block making business plan philippines couldn't be easier.