(Stanford users can avoid this Captcha by logging in.)

- Send to text email RefWorks EndNote printer

Operations research problems : statements and solutions

Available online.

- SpringerLink

More options

- Find it at other libraries via WorldCat

- Contributors

Description

Creators/contributors, contents/summary.

- Linear programming

- Integer programming

- Non-linear programming

- Network Modelling.-?Inventory theory

- Queuing theory

- Decision theory

- Game theory

- Dynamic programming

- Markov processes.

Bibliographic information

- Stanford Home

- Maps & Directions

- Search Stanford

- Emergency Info

- Terms of Use

- Non-Discrimination

- Accessibility

© Stanford University , Stanford , California 94305 .

Subjects Home

We will keep fighting for all libraries - stand with us!

Internet Archive Audio

- This Just In

- Grateful Dead

- Old Time Radio

- 78 RPMs and Cylinder Recordings

- Audio Books & Poetry

- Computers, Technology and Science

- Music, Arts & Culture

- News & Public Affairs

- Spirituality & Religion

- Radio News Archive

- Flickr Commons

- Occupy Wall Street Flickr

- NASA Images

- Solar System Collection

- Ames Research Center

- All Software

- Old School Emulation

- MS-DOS Games

- Historical Software

- Classic PC Games

- Software Library

- Kodi Archive and Support File

- Vintage Software

- CD-ROM Software

- CD-ROM Software Library

- Software Sites

- Tucows Software Library

- Shareware CD-ROMs

- Software Capsules Compilation

- CD-ROM Images

- ZX Spectrum

- DOOM Level CD

- Smithsonian Libraries

- FEDLINK (US)

- Lincoln Collection

- American Libraries

- Canadian Libraries

- Universal Library

- Project Gutenberg

- Children's Library

- Biodiversity Heritage Library

- Books by Language

- Additional Collections

- Prelinger Archives

- Democracy Now!

- Occupy Wall Street

- TV NSA Clip Library

- Animation & Cartoons

- Arts & Music

- Computers & Technology

- Cultural & Academic Films

- Ephemeral Films

- Sports Videos

- Videogame Videos

- Youth Media

Search the history of over 866 billion web pages on the Internet.

Mobile Apps

- Wayback Machine (iOS)

- Wayback Machine (Android)

Browser Extensions

Archive-it subscription.

- Explore the Collections

- Build Collections

Save Page Now

Capture a web page as it appears now for use as a trusted citation in the future.

Please enter a valid web address

- Donate Donate icon An illustration of a heart shape

Solutions Manual For Introduction To Operations Research 10th Edition By Frederick Hillier

Bookreader item preview, share or embed this item, flag this item for.

- Graphic Violence

- Explicit Sexual Content

- Hate Speech

- Misinformation/Disinformation

- Marketing/Phishing/Advertising

- Misleading/Inaccurate/Missing Metadata

Solutions Manual for Introduction To Operations Research 10th Edition tenth edition Book by Frederick S Hillier and Gerald J. Lieberman

Plus-circle add review comment reviews.

4,359 Views

2 Favorites

DOWNLOAD OPTIONS

For users with print-disabilities

IN COLLECTIONS

Uploaded by frank545 on October 10, 2020

Operations Research

Degree concentration for phd, industrial engineering.

Operations Research (OR) is the application of scientific and especially mathematical methods to the study and analysis of problems involving complex systems.

PhD students interested in OR apply methods such as mathematical programming, stochastic modeling, and discrete-event simulation to the solution of problems in complex systems such as logistics, supply chain optimization, long-range planning, energy and environmental systems, urban and health systems, and manufacturing.

We have an active student body - in fact, UB hosts one of the founding chapters of Omega Rho, the National Operations Research Honor Society. Students are also active participants in the Institute for Operations Research and the Management Sciences (INFORMS).

Our faculty and students conduct OR research funded by such agencies as the National Science Foundation, the Office of Naval Research, the Air Force Office of Scientific Research, the Department of Homeland Security, the Department of Transportation and the National Institute of Justice, as well as national and local corporations and foundations such as United Airlines, Praxair, Lockheed Martin, Boeing, and the Fire Protection Research Foundation. We often work in teams with faculty and students with research interests in manufacturing, production systems and human factors to solve problems beyond the expertise of any single discipline.

Graduating students take positions in national and international corporations, academic institutions and research laboratories.

Required Core Courses

ISE PhD students who concentrate in OR complete at a minimum:

- IE 572 Linear Programming

- IE 573 Discrete Optimization

- IE 575 Stochastic Methods

- IE 576 Applied Stochastic Processes

- IE 5xx/6xx Operations Research/IE Elective

- IE 555 Programming for Analytics (Must be completed within the first two years of the program)

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Transformations That Work

- Michael Mankins

- Patrick Litre

More than a third of large organizations have some type of transformation program underway at any given time, and many launch one major change initiative after another. Though they kick off with a lot of fanfare, most of these efforts fail to deliver. Only 12% produce lasting results, and that figure hasn’t budged in the past two decades, despite everything we’ve learned over the years about how to lead change.

Clearly, businesses need a new model for transformation. In this article the authors present one based on research with dozens of leading companies that have defied the odds, such as Ford, Dell, Amgen, T-Mobile, Adobe, and Virgin Australia. The successful programs, the authors found, employed six critical practices: treating transformation as a continuous process; building it into the company’s operating rhythm; explicitly managing organizational energy; using aspirations, not benchmarks, to set goals; driving change from the middle of the organization out; and tapping significant external capital to fund the effort from the start.

Lessons from companies that are defying the odds

Idea in Brief

The problem.

Although companies frequently engage in transformation initiatives, few are actually transformative. Research indicates that only 12% of major change programs produce lasting results.

Why It Happens

Leaders are increasingly content with incremental improvements. As a result, they experience fewer outright failures but equally fewer real transformations.

The Solution

To deliver, change programs must treat transformation as a continuous process, build it into the company’s operating rhythm, explicitly manage organizational energy, state aspirations rather than set targets, drive change from the middle out, and be funded by serious capital investments.

Nearly every major corporation has embarked on some sort of transformation in recent years. By our estimates, at any given time more than a third of large organizations have a transformation program underway. When asked, roughly 50% of CEOs we’ve interviewed report that their company has undertaken two or more major change efforts within the past five years, with nearly 20% reporting three or more.

- Michael Mankins is a leader in Bain’s Organization and Strategy practices and is a partner based in Austin, Texas. He is a coauthor of Time, Talent, Energy: Overcome Organizational Drag and Unleash Your Team’s Productive Power (Harvard Business Review Press, 2017).

- PL Patrick Litre leads Bain’s Global Transformation and Change practice and is a partner based in Atlanta.

Partner Center

An open-source framework for solving shop scheduling problems in manufacturing environments

- Original Research

- Published: 27 April 2024

Cite this article

- Carlos R. H. Márquez 1 ,

- Vanessa Braganholo 1 &

- Celso C. Ribeiro ORCID: orcid.org/0000-0002-9478-2351 1

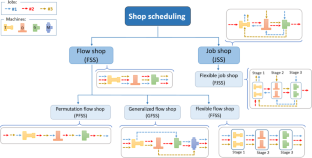

Scheduling problems refer to the decision-making process of allocating tasks to resources, usually scarce and in high demand, to optimize different performance measures. We consider the class of shop scheduling problems arising in the context of manufacturing systems, which are often NP-hard and challenging to solve. Exact methods have limitations in finding optimal solutions in reasonable computation times, even for instances of moderate size. Therefore, in real-life production environments, finding high-quality solutions is often satisfactory, even if they are not optimal. We contribute to the solution of shop scheduling problems with the design and implementation of the SSP-3M framework, oriented by three main guidelines: versatility, extensibility, and independence of the optimization method. These characteristics reduce the gap between scheduling theory and practice in real-life environments and improve the integration of the scheduling framework with other process planning or functions such as Computer-aided Process Planning, Advanced Planning and Scheduling, Integrated Process Planning and Scheduling, and Computer Integrated Manufacturing. The problem and solution representations adopted in our framework design make it possible to handle six shop scheduling problem variants, illustrating its versatility: job shop, flow shop, permutation flow shop, generalized flow shop, flexible flow shop, and flexible job shop. SSP-3M is open-source and can be used by any interested party. Our experimental evaluation shows that it can successfully be integrated with external optimization methods. We claim that SSP-3M is a good choice for companies that need free and quick-to-develop solutions to shop scheduling problems.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Data availability

The data that support the findings of this study are available from repositories at http://people.brunel.ac.uk/~mastjjb/jeb/orlib/flowshopinfo.html (Beasley, 2023 ), http://people.brunel.ac.uk/~mastjjb/jeb/orlib/jobshopinfo.html (Beasley, 2023 ), and https://people.idsia.ch/~monaldo/fjsp.html (Mastrolilli, 2023 ). Full numerical results are available at the project repository at https://github.com/cherreram2012/jssp-framework/wiki/Benchmark-results (Márquez, 2023 ).

Adams, J., Balas, E., & Zawack, D. (1988). The shifting bottleneck procedure for job shop scheduling. Management Science, 34 , 391–401.

Article Google Scholar

Agarwal, A., Colak, S., & Eryarsoy, E. (2006). Improvement heuristic for the flow-shop scheduling problem: An adaptive-learning approach. European Journal of Operational Research, 169 , 801–815.

Applegate, D., & Cook, W. (1991). A computational study of the job-shop scheduling problem. ORSA Journal on Computing, 3 , 149–156.

Arisha, A., & Young, P. (2001). Job shop scheduling problem: An overview. In International conference for flexible automation and intelligent manufacturing (pp. 682–693). Technological University Dublin.

Bagheri, A., Zandieh, M., Mahdavi, I., & Yazdani, M. (2010). An artificial immune algorithm for the flexible job-shop scheduling problem. Future Generation Computer Systems, 26 , 533–541.

Bahouth, S. (2014). Taxonomy of shop scheduling. Online Reference Available at SSRN https://doi.org/10.2139/ssrn.2447152 . Accessed January 8, 2023.

Beasley, J. E. (2023). OR-Library: Flow shop scheduling . Online reference at http://people.brunel.ac.uk/~mastjjb/jeb/orlib/flowshopinfo.html . Accessed June 8, 2023.

Beasley, J. E. (2023). OR-Library: Job shop scheduling . Online reference at http://people.brunel.ac.uk/~mastjjb/jeb/orlib/jobshopinfo.html . Accessed June 8, 2023.

Behnke, D., & Geiger, M. J. (2012). Test instances for the flexible job shop scheduling problem with work centers . Technical Report RR-12-01-01. Helmut-Schmidt Universitat.

Bidot, J., Vidal, T., Laborie, P., & Beck, J. C. (2009). A theoretic and practical framework for scheduling in a stochastic environment. Journal of Scheduling, 12 , 315–344.

Bierwirth, C. (1995). A generalized permutation approach to job shop scheduling with genetic algorithms. OR Spektrum, 17 , 87–92.

Bierwirth, C., & Mattfeld, D. C. (1999). Production scheduling and rescheduling with genetic algorithms. Evolutionary Computation, 7 , 1–17.

Blażewicz, J., Ecker, K., Pesch, E., Schmidt, G., & Wȩglarz, J. (2007). Handbook on scheduling: From theory to applications . Springer.

Brandimarte, P. (1993). Routing and scheduling in a flexible job shop by tabu search. Annals of Operations Research, 41 , 157–183.

Brucker, P. (2007). Scheduling algorithms (5th ed.). Springer.

Google Scholar

Brucker, P., Jurisch, B., & Sievers, B. (1994). A branch and bound algorithm for the job-shop scheduling problem. Discrete Applied Mathematics, 49 , 107–127.

Buxey, G. (1989). Production scheduling: Practice and theory. European Journal of Operational Research, 39 , 17–31.

Fang, H., Ross, P., & Corne, D. (1993). A promising genetic algorithm approach to job-shop scheduling, rescheduling, and open-shop scheduling problems. In S. Forrest (Ed.), Proceedings of the fifth international conference on genetic algorithms (pp. 375–382). Morgan Kaufmann.

Fisher, H., & Thompson, G. L. (1963). Probabilistic learning combinations of local job shop scheduling rules. In J. F. Muth & G. L. Thompson (Eds.), Industrial scheduling (pp. 225–251). Prentice Hall.

Framinan, J. M., & Ruiz, R. (2010). Architecture of manufacturing scheduling systems: Literature review and an integrated proposal. European Journal of Operational Research, 205 , 237–246.

Framinan, J. M., & Ruiz, R. (2012). Guidelines for the deployment and implementation of manufacturing scheduling systems. International Journal of Production Research, 50 , 1799–1812.

Fumagalli, L., Macchi, M., Negri, E., Polenghi, A., & Sottoriva, E. (2017). Simulation-supported framework for job shop scheduling with genetic algorithm. In Proceedings of the summer School Francesco Turco (Vol. 2017, pp. 271–278).

Giffler, B., & Thompson, G. L. (1960). Algorithms for solving production-scheduling problems. Operations Research, 8 , 487–503.

Heller, J. (1960). Some numerical experiments for an \({M} \times {J}\) flow shop and its decision-theoretical aspects. Operations Research, 8 , 178–184.

Holsapple, C. W., Jacob, V. S., Pakath, R., & Zaveri, J. S. (1993). A genetics-based hybrid scheduler for generating static schedules in flexible manufacturing contexts. IEEE Transactions on Systems, Man, and Cybernetics, 23 , 953–972.

King, J. R. (1976). The theory-practice gap in job-shop scheduling. The Production Engineer, 55 , 137–143.

Lau, H. Y. K., & Qiu, X. (2014). An artificial immune systems (AIS)-based unified framework for general job shop scheduling. IFAC Proceedings Volumes, 47 , 6186–6191.

Lawrence, S. (1984). Resource constrained project scheduling: An experimental investigation of heuristic scheduling techniques (Supplement) . Technical report. Carnegie-Mellon University.

Lee, C.-Y., Piramuthu, S., & Tsai, Y.-K. (1997). Job shop scheduling with a genetic algorithm and machine learning. International Journal of Production Research, 35 , 1171–1191.

Liu, W., Jin, Y., & Price, M. (2017). A new improved NEH heuristic for permutation flowshop scheduling problems. International Journal of Production Economics, 193 , 21–30.

Liu, W., Ma, W., Hu, Y., Jin, M., Li, K., Chang, X., & Yu, X. (2019). Production planning for stochastic manufacturing/remanufacturing system with demand substitution using a hybrid ant colony system algorithm. Journal of Cleaner Production, 213 , 999–1010.

Márquez, C. R. H. (2023). Benchmark results for the SSP-3M framework . Online reference at https://github.com/cherreram2012/jssp-framework/wiki/Benchmark-results . Accessed June 5, 2023.

Márquez, C. R. H. (2023). SSP-3M framework repository . Online reference at https://github.com/cherreram2012/jssp-framework . Accessed June 5, 2023.

Márquez, C. R. H., & Ribeiro, C. C. (2022). Shop scheduling in manufacturing environments: A review. International Transactions in Operational Research, 29 , 3237–3293.

Mastrolilli, M. (2023). Flexible Job Shop Problem . Online reference at https://people.idsia.ch/~monaldo/fjsp.html . Accessed June 8, 2023.

McKay, K. N., & Buzacott, J. A. (2000). Application of computerized production control systems in job shop environments. Computers in Industry, 42 , 79–97.

Nawaz, M., Enscore, E. E., & Ham, I. (1983). A heuristic algorithm for the \(m\) -machine, \(n\) -job flow-shop sequencing problem. Omega, 11 , 91–95.

Pfeiffer, A., Kádár, B., & Monostori, L. (2006). Stability-oriented evaluation of rescheduling strategies, by using simulation. Computers in Industry, 35 , 563–570.

Pinedo, M. L. (2012). Scheduling: Theory, algorithms and systems . Springer.

Book Google Scholar

Pinedo, M., & Yen, B. P. C. (1997). On the design and development of object-oriented scheduling systems. Annals of Operations Research, 70 , 359–378.

Pongcharoen, P., Hicks, C., & Braiden, P. M. (2004). The development of genetic algorithms for the finite capacity scheduling of complex products, with multiple levels of product structure. European Journal of Operational Research, 152 , 215–225.

Reisman, A., Kumar, A., & Motwani, J. (1997). Flowshop scheduling/sequencing research: A statistical review of the literature, 1952–1994. IEEE Transactions on Engineering Management, 44 , 316–329.

Resende, M. G. C., & Ribeiro, C. C. (2016). Optimization by GRASP: Greedy randomized adaptive search procedures . Springer.

Resende, M. G. C., Ribeiro, C. C., Glover, F., & Martí, R. (2010). Scatter search and path-relinking: Fundamentals, advances, and applications. In M. Gendreau & J.-Y. Potvin (Eds.), Handbook of metaheuristics , 2nd edn (pp. 87–107). Springer.

Resende, M. G. C., & Ribeiro, C. C. (2005). GRASP with path-relinking: Recent advances and applications. In T. Ibaraki, K. Nonobe, & M. Yagiura (Eds.), Metaheuristics: Progress as real problem solvers (pp. 29–63). Springer.

Chapter Google Scholar

Ribeiro, C. C., & Resende, M. G. C. (2012). Path-relinking intensification methods for stochastic local search algorithms. Journal of Heuristics, 18 , 193–214.

Romero-Silva, R., Santos, J., & Hurtado, M. (2015). A framework for studying practical production scheduling. Production Planning & Control, 26 , 438–450.

Roy, B., & Sussmann, B. (1964). Les problemes d’ordonnancement avec contraintes disjonctives . Technical report. SEMA.

Salido, M. A., Escamilla, J., Barber, F., & Giret, A. (2017). Rescheduling in job-shop problems for sustainable manufacturing systems. Journal of Cleaner Production, 162 , 121–132.

Sun, D., & Lin, L. (1994). A dynamic job shop scheduling framework: A backward approach. International Journal of Production Research, 32 , 967–985.

Taillard, E. (1993). Benchmarks for basic scheduling problems. European Journal of Operational Research, 64 , 278–285.

Vieira, G. E., Herrmann, J. W., & Lin, E. (2003). Rescheduling manufacturing systems: A framework of strategies, policies, and methods. Journal of Scheduling, 6 , 39–62.

Wall, M. (1996). GAlib: A C++ Library of genetic algorithm components . Online reference at http://lancet.mit.edu/ga/ . Accessed May 7, 2023.

Xia, W.-J., & Wu, Z.-M. (2006). A hybrid particle swarm optimization approach for the job-shop scheduling problem. The International Journal of Advanced Manufacturing Technology, 29 , 360–366.

Yamada, T. (2003). Studies on metaheuristics for jobshop and flowshop scheduling problems . PhD thesis, Kyoto University.

Yen, B. P. C., & Pinedo, M. (1994). On the design and development of scheduling systems. In Proceedings of the fourth international conference on computer integrated manufacturing and automation technology (pp. 197–204). IEEE Computer Society Press.

Download references

Acknowledgements

The work of Celso C. Ribeiro was supported by research grants CNPq 309869/2020-0 and FAPERJ E-26/200.926/2021. Vanessa Braganholo was supported by research grant CNPq 305020/2019-6.

Author information

Authors and affiliations.

Institute of Computing, Universidade Federal Fluminense, Niterói, Brazil

Carlos R. H. Márquez, Vanessa Braganholo & Celso C. Ribeiro

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Celso C. Ribeiro .

Ethics declarations

Conflict of interest.

The authors have no conflict of interest to declare that are relevant to the content of this article.

Software availability statement

The open-source, ready-to-use framework SSP-3M coded in C++ is available at the project repository at https://github.com/cherreram2012/jssp-framework (Márquez, 2023 ).

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

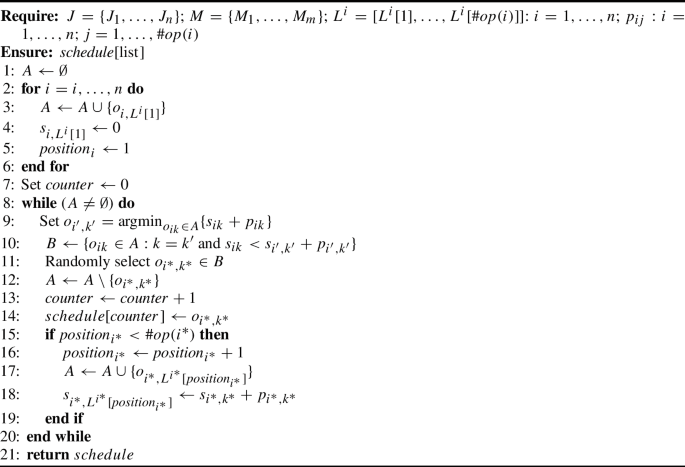

Appendix A: Greedy randomized G &T algorithm

The greedy randomized G &T algorithm of Giffler and Thompson ( 1960 ) takes as input the set of jobs \(J=\{J_1,\ldots ,J_n\}\) , the set of machines \(M=\{M_1,\ldots ,M_m\}\) , and, for each job \(J_i\) , \(i=1,\ldots ,n\) , the number of operations \(\#op(i)\) to be processed, a list \(L^i = [L^i[1],\ldots ,L^i[\#op(i)]]\) with the sequence of machines where it has to be processed, and the processing times \(p_{i,1},\ldots ,p_{i,\#op(i)}\) of each operation. The algorithm outputs a schedule represented by an operation sequence (possibly with repetitions), with each operation defined by a job, a machine, and the time this job should start to be processed in this machine. The main steps of its pseudo-code appear in Algorithm 1, which is our formalization of the original algorithm textually described in Giffler and Thompson ( 1960 ).

Line 1 initializes the set A that stores the candidate operations, i.e., those that are ready to be scheduled. Each iteration \(i=1,\ldots ,n\) of the loop in lines 2 to 6 places the first operation of job \(J_i\) in the candidate set A in line 3 and sets its starting time to 0 in line 4. Line 5 sets to 1 the position of the first operation of job \(J_i\) ready to be scheduled. Line 7 sets to 0 the counter of scheduled operations. The while loop in lines 8 to 20 runs until all operations are scheduled. Line 9 selects from the candidate set A the operation \(o_{i',k'}\) with the shortest completion time, corresponding to the execution of job \(J_{i'}\) in machine \(M_{k'}\) . Line 10 creates the set \(B \subseteq A\) formed by the candidate operations that guarantee the construction of an active schedule. It contains all operations that use machine \(M_{k'}\) and may start before the shortest completion time determined in line 9. Line 11 randomly selects an operation \(o_{i^*,k^*}\) from B . Line 12 removes the newly selected operation from the candidate set A . Line 13 updates the counter of scheduled operations, and line 14 schedules operation \(o_{i^*,k^*}\) in this position of the operation sequence. Line 15 checks if operation \(o_{i^*,k^*}\) is not the last of job \(J_{i^*}\) . In this case, line 16 updates the position of the subsequent operation of job \(J_{i^*}\) ready to be scheduled. Line 17 adds the next operation of job \(J_i\) to the candidate set A , and its starting time is set to the completion time of operation \(o_{i^*,k^*}\) in line 18. Line 21 returns the schedule represented as an operation sequence.

G &T algorithm

We remark that other dispatching rules can be used at step 11 instead of a simple random choice, such as shortest processing time (SPT), longest processing time (LPT), start as-early-as-possible (SEP), earliest completion time (ECT), earliest due date (EDD), longest number of successors (LNS), and shortest number of successors (SNS). They all lead to active schedules and different variants of the algorithm (Pfeiffer et al., 2006 ).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Márquez, C.R.H., Braganholo, V. & Ribeiro, C.C. An open-source framework for solving shop scheduling problems in manufacturing environments. Ann Oper Res (2024). https://doi.org/10.1007/s10479-024-05995-6

Download citation

Received : 01 September 2023

Accepted : 08 April 2024

Published : 27 April 2024

DOI : https://doi.org/10.1007/s10479-024-05995-6

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Scheduling framework

- Shop scheduling

- Manufacturing systems

- Job shop problem

- Flow shop problem

- Scheduling algorithms

- Combinatorial optimization

- Open-source

- Manufacturing environment

- Find a journal

- Publish with us

- Track your research

IMAGES

VIDEO

COMMENTS

The transportation problem is a classic problem in operations research that involves finding the optimal way to move goods from one place to another. ... As the need for efficient, cost-effective solutions continues to grow, the field of transportation problems and their solutions will remain a critical area of research and Peter Malacký et ...

The objective of this book is to provide a valuable compendium of problems as a reference for undergraduate and graduate students, faculty, researchers and practitioners of operations research and management science. These problems can serve as a basis for the development or study of assignments and exams. Also, they can be useful as a guide ...

The last phase, interpretation, encompasses making a decision and developing implementation plans. The paragraphs below explain the seven elements of the operations research problem solving process in greater detail. The activities that take place in each element are illustrated through some of the tools or methods commonly used.

Operations research (OR) has been an academic and industry focus that has gained prominence since World War II, being used to optimize, predict and solve challenging problems across many sectors. ... is a relaxed solution, z IP * (1) is a feasible solution to the problem. The optimal integer solution exists between these bounds. Upon completing ...

speaking, an O.R. project comprises three steps: (1) building a model, (2) solving it, and. (3) implementing the results. The emphasis of this chapter is on the first and third steps. The second step typically involves specific methodologies or techniques, which could be.

Operations research is a multidisciplinary field that is concerned with the application of mathematical and analytic techniques to assist in decision-making. It includes techniques such as mathematical modelling, statistical analysis, and mathematical optimization as part of its goal to achieve optimal (or near optimal) solutions to complex ...

The subject matter, operations research or management science (even though there may be philosophical differences, we use the two terms interchangeably), has been defined by many researchers in the field. Definitions range from "a scientific approach to decision making" to "the use of quantitative tools for systems that originate from real life," "scientific decision making," and ...

Markov processes. Summary. The objective of this book is to provide a valuable compendium of problems as a reference for undergraduate and graduate students, faculty, researchers and practitioners of operations research and management science. These problems can serve as a basis for the development or study of assignments and exams.

By. Sarah Lewis. Operations research (OR) is an analytical method of problem-solving and decision-making that is useful in the management of organizations. In operations research, problems are broken down into basic components and then solved in defined steps by mathematical analysis. The process of operations research can be broadly broken ...

operations research, application of scientific methods to the management and administration of organized military, governmental, commercial, and industrial processes.. Basic aspects. Operations research attempts to provide those who manage organized systems with an objective and quantitative basis for decision; it is normally carried out by teams of scientists and engineers drawn from a ...

Operations research - Modeling, Solutions, Analysis: Procedures for deriving solutions from models are either deductive or inductive. With deduction one moves directly from the model to a solution in either symbolic or numerical form. ... Through controls the problem-solving system of which operations research is a part learns from its own ...

Operations research - Problem-Solving, Modeling, Analysis: Three essential characteristics of operations research are a systems orientation, the use of interdisciplinary teams, and the application of scientific method to the conditions under which the research is conducted. The systems approach to problems recognizes that the behaviour of any part of a system has some effect on the behaviour ...

production department. While dealing with the operations research problems, we have to consider the entire system and characteristics or sub-systems, the inter-relationship between the sub-systems and then analyse the problem, search for a suitable model and get the solution for the problem. Introduction to Operations Research 3

Solutions 56:171 Operations Research Final Exam '98 page 1 of 14 tststst 56:171 Operations Research tststst stststs Final Examination Solutions ststst tststst Fall 1998 tststst • Write your name on the first page, and initial the other pages. • Answer both Parts A and B, and 4 (out of 5) problems from Part C. Possible

Books. Operations Research (3 Edition) : Problems & Solutions. Sharma. Macmillan Publishers India Limited, 2008 - 912 pages. This revised edition elucidates the key concepts and methods of operations research. It aims to supplement textbooks on Operations Research (OR) and upgrade student s knowledge and skills in the subject. Salient features ...

Operations Research (OR) is the study of mathematical models for complex organizational systems. Optimization is a branch of OR which uses mathematical techniques such as linear and nonlinear programming to derive values for system variables that will optimize performance. Introduction to Operations Research - p.5

chapter 01: graphical solutions to linear operations research problems. chapter 02: linear programming(lp) - introduction. chapter 03: linear programming - the simplex method. chapter 04: linear programming-advanced methods. chapter 05: the transportation and assignment problems

Solutions Manual for Introduction To Operations Research 10th Edition tenth edition Book by Frederick S Hillier and Gerald J. Lieberman. ... solutions-manual-for-introduction-to-operations-research-10th-edition-by-frederick-hillier Identifier-ark ark:/13960/t3232cx0p Ocr ABBYY FineReader 11.0 (Extended OCR) ...

Operations research is, in principle, the application of scientific methods, techniques, and tools for solving problems involving the operations of a system in order to provide those in control of the system with optimum solutions to problems. Put simply, it is a systematic and analytical approach to decision making and problem solving.

Operation Research calculators - Solve linear programming problems of Operations Research, step-by-step online. We use cookies to improve your experience on our site and to show you relevant advertising. By browsing this website, you agree to our use of cookies. ... Find initial basic feasible solution for given problem by using (a) ...

For Engineering, Computer Science, Commerce and Management, Economics, Statistics, Mathematics, C.A., I.C.W.A.,C.S. Also useful for I.A.S. and other Competitive Examinaions. Many new exercises from the latest examination papers have been included along with hints for all difficult exercises. The book now covers questions upto 2008 examinations.

MS students interested in operations research apply methods such as mathematical programming, stochastic modeling, and discrete-event simulation to the solution of problems in complex systems such as logistics, supply chain optimization, long-range planning, energy and environmental systems, urban and health systems, and manufacturing.

Operations research is the application of scientific and especially mathematical methods to the study and analysis of problems involving complex systems. ... and discrete-event simulation to the solution of problems in complex systems such as logistics, supply chain optimization, long-range planning, energy and environmental systems, urban and ...

The concept of an "optimum" solution is defined in terms of the objective of an operations-research effort. An operational, technological, and investment objective is discussed and three separate formulations for a typical problem in the petroleum industry are developed in accordance with each approach. Previous.

This paper outlines the core themes covered in our research, including the classification of optimization problems, the utilization of mathematical models, and the development of algorithmic solutions. It highlights the importance of algorithm selection and design in achieving optimal solutions for diverse operations research problems.

Director of George Mason University's Master of Science in Business Analytics (MSBA) program, Mehmet Altug, found his passion while studying industrial engineering as an undergraduate. Altug says he took classes on manufacturing management, supply chain planning, and operations research, and liked the combination of quantitative models and business problems. Fast forward to today, and Altug ...

The Problem. Although companies frequently engage in transformation initiatives, few are actually transformative. Research indicates that only 12% of major change programs produce lasting results.

As a classical combinatorial optimization problem, the traveling salesman problem (TSP) has been extensively investigated in the fields of Artificial Intelligence and Operations Research. Due to being NP-complete, it is still rather challenging to solve both effectively and efficiently. Because of its high theoretical significance and wide practical applications, great effort has been ...

No industry is free of violence, but the problem is prevalent in the service sector. For example, in 2021, 10,490 violent crimes were reported in U.S. restaurants.

Scheduling problems refer to the decision-making process of allocating tasks to resources, usually scarce and in high demand, to optimize different performance measures. We consider the class of shop scheduling problems arising in the context of manufacturing systems, which are often NP-hard and challenging to solve. Exact methods have limitations in finding optimal solutions in reasonable ...