Wheat Flour Mill Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Agriculture Sector » Agro Processing

Are you about starting a wheat flour mill? If YES, here is a complete sample wheat flour production business plan template & feasibility report you can use for FREE .

Okay, so we have considered all the requirements for starting a wheat flour production business. We also took it further by analyzing and drafting a sample wheat flour mill marketing plan template backed up by actionable guerrilla marketing ideas for wheat flour production businesses. So let’s proceed to the business planning section.

As an aspiring entrepreneur who is looking towards starting a business and becoming your own boss, one of the businesses that you can successfully start if you have the financial requirement and of course business expose is to open a wheat flour production mill.

Suggested for You

- Vegetable Oil Production Business Plan [Sample Template]

- Mustard Oil Production Business Plan [Sample Template]

- Tree Surgery Business Plan [Sample Template]

- Ginger Processing Business Plan [Sample Template]

- Pickle Business Plan (Sample Template)

Although this type of business is not a business that you can start making profits from instantly, but a you are sure going to make good profits in the long run if you are determined and proactive in running the business. The reason is not far – fetched; you will require huge capital to set – up a standard wheat flour production mill. This type of business can somewhat be capital intensive.

Beyond every reasonable doubt, wheat flour is consumed in all parts of the world either as flour or the flour is used in the production of bread and other baked foods.

This goes to show that there is indeed a large market both locally and internationally for wheat flour production companies. Below is a sample wheat flour production mill business plan template that can help you to successfully write your own.

A Sample Wheat Flour Production Mill Business Plan Template

1. industry overview.

Wheat flour production companies in basically engaging in milling wheat grains into flour and then package and sell them to wholesale distributors, grocery wholesalers or other food-related business. They purchase wheat grain inputs from wholesalers or directly from growers.

The main fact that wheat flour mills provide goods that are considered diet staples, the industry will remain relevant in the years to come. The revenue and profit generated from this industry will depend on the price and production of wheat. As companies vertically integrate and merge operations to take advantage of economies of scale, revenue will rise.

According to a report released by IBISWORLD, the Flour Milling industry of which Wheat Flour Mill Production line of business is a part of is characterized by a low level of market share concentration. The report stated that in 2016, the top three players are expected to account for less than 31.0 percent of industry revenue.

While the industry exhibits low concentration, the industry is expected to approach moderate concentration over the next five years in line with the entrance of larger flour milling companies.

The report also stated that, in 2014, Ardent Mills entered the industry, as a result of ConAgra Mills and Horizon Milling, which is a joint venture between Cargill and CHS, combining their flour milling operations. Overall, larger operations will enable flour milling companies to use their large size to leverage lower costs for input commodities, such as wheat and grains

The Flour Production Mill industry of which wheat flour mill production line of business is subset of is a thriving sector of the economy of the united states of America and they generates a whooping sum of well over billion annually from more than 403 registered and licensed wheat flour mill production companies scattered all around the United States of America.

The industry is responsible for the employment of well over 24,938 people. Experts project the wheat flour mill production industry to grow at a -1.2 percent annual rate. Archer Daniels Midland Company, Ardent Mills, ConAgra Mills and Horizon Milling are the market leaders in the wheat flour production mill industry; they have the lion market share in the United States of America.

With this kind of business, if you want to start on a small scale, you can choose to start servicing your local community. All you would need is contacts, packaging, networking and good marketing and customer service skills. However, if you intend starting it on a large scale, then you should consider spreading beyond your local community to state level and even national level.

Over and above, the wheat flour production mill line of business is a profitable industry and it is open for any aspiring entrepreneur to come in and establish his or her business; you can chose to start on a small scale servicing a community or you can chose to start on a large scale with several distribution outlets in key cities all around the United States of America.

2. Executive Summary

Sammy Jay® Wheat Flour Production Company is a licensed and standard wheat flour mill production company that will be located in an industrial area in Springfield – Illinois. We have been able to secure a long term lease for a facility in a strategic location close to a big wheat farm with an option of a long term renewal on an agreed terms and conditions that is favorable to us.

The facility has government approval for the kind of business we want to run and it is easily accessible and we are deliberate about that to facilitate easy movement of raw materials (wheat grains and packaging materials et al) and finished products (well packaged wheat flour).

We are in the wheat flour mill production business to engage in processing, packaging and retailing wheat flour. We are also in business to make profits at the same to give our customers value for their money; we want to give people and businesses who patronize our well – packaged wheat flour the opportunity to be part of the success story of Sammy Jay® Wheat Flour Production Company.

We are aware that there are several big scale and small scale wheat flour mill production companies scattered all around the United States and Canada whose products can be found in every nooks and crannies of The United States and Canada.

Which is why we spent time and resources to conduct our feasibility studies and market survey so as to enable us locate the business in an area that will support the growth of the business and also for us to be able offer much more than our competitors will be offering.

We ensured that our facility is easy to locate and we have mapped out plans to develop a wide distribution network for wholesalers all around Springfield – Illinois and throughout the United States of America.

Much more than producing healthy, well processed and well packaged wheat flour, our customer care is going to be second to none. We know that our customers are the reason why we are in business which is why we will go the extra mile to get them satisfied when they visit purchase our wheat flour warehouse and also to become our loyal customers and ambassadors.

Sammy Jay® Wheat Flour Production Company will ensure that all her customers (wholesale distributors) are given first class treatment whenever they visit our flour mill or warehouse.

We have a CRM software that will enable us manage a one on one relationship with our customers (wholesale distributors) no matter how large the numbers of our customer base may grow to. We will ensure that we get our customers involved when making some business decisions that will directly or indirectly affect them.

Sammy Jay® Wheat Flour Production Company is family business that will be owned and managed by Sammy Jay and his immediate family members. Sammy Jay who is the Chief Executive Officer of the Company is Graduate of MicroBiology (B.Sc.) and he holds a Master’s Degree in Business Management (MBA).

He has well over 10 years of experience working in related industry as a senior manager prior to starting Sammy Jay® Wheat Flour Production Company. He will be working with a team of professionals to build the business and grow it to enviably height.

3. Our Products and Services

Sammy Jay® Wheat Flour Production Company is going to operate a standard and licensed wheat flour mill production company whose products will not only be sold in Springfield – Illinois but also throughout the United States of America.

We are in this line of business to make profits and also to give our customers value for their money. We are going to do all that is permitted by the law of the United States to achieve our business aim and ambition. Our product offering will be;

- Processing, packaging and retailing wheat flour in commercial quantities

4. Our Mission and Vision Statement

- Our vision is to establish standard Wheat Flour Production Company whose products will not only be sold in Springfield – Illinois, but also throughout the United States of America and Canada.

- Our mission is to establish a standard and world class Wheat Flour Mill Production Company that in our own capacity will favorably compete with leaders in the industry. We want to build a wheat flour mill production business that will be listed amongst the top 10 wheat flour mill brands in the United States of America and Canada

Our Business Structure

Sammy Jay® Wheat Flour Production Company is a business that is established with the aim of competing favorably with other leading wheat flour brands in the United States of America and Canada. This is why we will ensure that we put the right structure in place that will support the kind of growth that we have in mind while setting up the business.

We will ensure that we only hire people that are qualified, honest, hardworking, customer centric and are ready to work to help us build a prosperous business that will benefit all the stakeholders (the owners, workforce, and customers).

As a matter of fact, profit-sharing arrangement will be made available to all our senior management staff and it will be based on their performance for a period of five years or more depending how fast we meet our set target. In view of that, we have decided to hire qualified and competent hands to occupy the following positions;

- Chief Executive Officer (Owner)

Plant Manager

Human Resources and Admin Manager

Merchandize Manager

Sales and Marketing Manager

- Machine Operators

- Accountants / Cashiers

Distribution Truck Drivers

5. Job Roles and Responsibilities

Chief Executive Officer – CEO (Owner):

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- Creates, communicates, and implements the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Responsible for fixing prices and signing business deals

- Responsible for providing direction for the business

- Responsible for signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Responsible for overseeing the smooth running of the wheat flour mill

- Part of the team that determines the quantity of wheat flour bags that are to be produced

- Maps out strategy that will lead to efficiency amongst workers in the plant

- Responsible for training, evaluation and assessment of plant workers

- Ensures that the steady flow of both raw materials to the plant and easy flow of finished products through wholesale distributors to the market

- Ensures operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Ensures that the plant meets the expected safety and health standard at all times.

- Responsible for overseeing the smooth running of HR and administrative tasks for the organization

- Updates job knowledge by participating in educational opportunities; reading professional publications; maintaining personal networks; participating in professional organizations.

- Enhances department and organization reputation by accepting ownership for accomplishing new and different requests; exploring opportunities to add value to job accomplishments.

- Defines job positions for recruitment and managing interviewing process

- Carries out staff induction for new team members

- Responsible for training, evaluation and assessment of employees

- Oversees the smooth running of the daily office and factory activities.

- Manages vendor relations, market visits, and the ongoing education and development of the organizations’ buying teams

- Helps to ensure consistent quality of wheat grains and packaging materials are purchased

- Responsible for the purchase of raw materials and packaging materials (wheat grains and packaging materials et al)

- Responsible for planning sales, monitoring inventory, selecting the merchandise, and writing and pricing orders to vendors

- Ensures that the organization operates within stipulated budget.

- Manages external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Models demographic information and analyze the volumes of transactional data generated by customer purchases

- Identifies, prioritizes, and reaches out to new partners, and business opportunities et al

- Responsible for supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develops, executes and evaluates new plans for expanding increase sales

- Documents all customer contact and information

- Represents the company in strategic meetings

- Helps to increase sales and growth for the company

Accountant / Cashier

- Responsible for preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyzes financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- Responsible for financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting

- Responsible for developing and managing financial systems and policies

- Responsible for administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the organization

- Serves as internal auditor for the organization

Client Service Executive

- Ensures that all contacts with customer (e-mail, walk-In center, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with customers on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Manages administrative duties assigned by the store manager in an effective and timely manner

- Consistently stays abreast of any new information on Sammy Jay® Wheat Flour Production Company products, promotional campaigns etc. to ensure accurate and helpful information is supplied to clients when they make enquiries

Production Workers / Machine Operators:

- Responsible for processing and packaging (bagging) wheat flour

- Assists in packaging and loading wheat flour (bags) into distribution trucks

- Any other duty as assigned by the plant manager.

- Assists in loading and unloading wheat grains and wheat flour (bags)

- Maintains a logbook of their driving activities to ensure compliance with federal regulations governing the rest and work periods for operators.

- Keeps a record of vehicle inspections and make sure the truck is equipped with safety equipment

- Assists the transport and logistics manager in planning their route according to a delivery schedule.

- Local-delivery drivers may be required to sell products or services to stores and businesses on their route, obtain signatures from recipients and collect cash.

- Transports finished goods and raw materials over land to and from manufacturing plants or retail and distribution centers

- Inspects vehicles for mechanical items and safety issues and perform preventative maintenance

- Complies with truck driving rules and regulations (size, weight, route designations, parking, break periods etc.) as well as with company policies and procedures

- Collects and verifies delivery instructions

- Reports defects, accidents or violations

6. SWOT Analysis

We are well informed that there are several wheat flour mill production companies both large and small in the United States of America and Canada which is why we are following the due process of establishing a business so as to compete favorable with them.

We know that if a proper SWOT analysis is conducted for our business, we will be able to position our business to maximize our strength, leverage on the opportunities that will be available to us, mitigate our risks and be welled equipped to confront our threats.

Sammy Jay® Wheat Flour Production Company employed the services of an expert HR and Business Analyst with bias in start – up business to help us conduct a thorough SWOT analysis and to help us create a Business model that will help us achieve our business goals and objectives. This is the summary of the SWOT analysis that was conducted for Sammy Jay® Wheat Flour Production Company;

Part of what is going to count as positives for Sammy Jay® Wheat Flour Production Company is the vast experience of our management team, we have people on board who are highly experienced and understands how to grow business from the scratch to becoming a national phenomenon.

So also, proximity to one of the largest wheat grain farms in Springfield – Illinois, our large national distribution network and of course our excellent customer service culture will definitely count as a strong strength for the business.

A major weakness that may count against us is the fact that we are a new wheat flour mill production company and we don’t have the financial capacity to engage in the kind of publicity that we intend giving the business.

- Opportunities:

The fact that wheat flour is stable food in the United States and in all the countries of the world means that the opportunity available to us is enormous.

As a result of that, we were able to conduct a thorough market survey and feasibility studies so as to enable us properly position our business to take advantage of the existing market for wheat flour and also to create our own new market. We know that it is going to requires hard work, and we are well prepared to achieve it.

We are quite aware that just like any other business, one of the major threats that we are likely going to face is economic downturn and unfavorable government policies . It is a fact that economic downturn affects purchasing power.

Another threat that may likely confront us is the arrival of a new wheat flour mill production company in same location where ours is located. Changing diet preference may also pose a threat to wheat flour mill production companies.

7. MARKET ANALYSIS

- Market Trends

IBISWORLD published a report that stated that the Flour Milling industry of which Wheat Flour Mill Production line of business is a part of is characterized by a low level of market share concentration.

The report stated that in 2016, the top three players are expected to account for less than 31.0 percent of industry revenue. While the industry exhibits low concentration, the industry is expected to approach moderate concentration over the next five years in line with the entrance of larger flour milling companies.

The report also stated that, in 2014, Ardent Mills entered the industry, as a result of ConAgra Mills and Horizon Milling, which is a joint venture between Cargill and CHS, combining their flour milling operations.

Overall, larger operations will enable flour milling companies to use their large size to leverage lower costs for input commodities, such as wheat and grains.

If you are conversant with the trends in amongst wheat flour mill production companies, you will realize that in the bid to expanding their brand and generate enough income, they do not just settle for just the production of wheat flour, they also engage in related activities such as producing flour from corn, producing flour mixes from a variety of grain crops, milling rough rice, producing malt from a variety of cereal grains, and producing meal and animal feed

They are able to achieve this because the processes and machine involved are same as that required for milling wheat grains into fine wheat flour. With this, they are able to maximize their capacity and make good profits from the business.

8. Our Target Market

When it comes to selling wheat flour, there is indeed a wide range of available customers. In essence, our target market can’t be restricted to just a group of people, but all those who resides in our target market locations. In view of that, we have conducted our market research and we have ideas of what our target market would be expecting from us.

We are in business to engage in wholesale distribution and to retail well – packaged wheat flour in different sizes to the following groups of people;

- Restaurants and Canteens

- Event Planners and Caterers

- Everybody in our target market location

Our Competitive Advantage

A close study of the wheat flour mill production industry reveals that the market has become much more intensely competitive over the last decade. As a matter of fact, you have to be highly creative, customer centric and proactive if you must survive in this industry.

We are aware of the stiffer competition and we are well prepared to compete favorably with other wheat flour mill production companies in Springfield – Illinois and throughout the United States and Canada.

Sammy Jay® Wheat Flour Production Company is launching a standard wheat flour brand that will indeed become the preferred choice of residence of Springfield – Illinois and every city where our well – packaged wheat flour will be distributed and retailed.

Part of what is going to count as competitive advantage for Sammy Jay® Wheat Flour Production Company is the vast experience of our management team, we have people on board who are highly experienced and understands how to grow business from the scratch to becoming a national phenomenon.

So also proximity to one of the largest wheat grain farms in Springfield – Illinois, our large national distribution network and of course our excellent customer service culture will definitely count as a strong strength for the business.

Lastly, our employees will be well taken care of, and their welfare package will be among the best within our category (startups wheat flour mill production companies) in the industry, meaning that they will be more than willing to build the business with us and help deliver our set goals and achieve all our aims and objectives.

We will also give good working conditions and commissions to freelance sales agents that we will recruit from time to time.

9. SALES AND MARKETING STRATEGY

- Sources of Income

Sammy Jay® Wheat Flour Production Company is established with the aim of maximizing profits in the wheat flour mill production industry in both the United States of America and Canada and we are going to go all the way to ensure that we do all it takes to sell our well processed and well – bagged wheat flour to a wide range of customers.

Sammy Jay® Wheat Flour Production Company will generate income by processing, packaging, distributing and retailing wheat flour.

10. Sales Forecast

One thing is certain when it comes to wheat flour production business, if your wheat flour are well – packaged and branded and if your production mill is centrally positioned and easily accessible, you will always attract customers cum sales and that will sure translate to increase in revenue generation for the business.

We are well positioned to take on the available market in Springfield – Illinois and every city where our well processed and well – packaged wheat flour will be distributed and retailed and we are quite optimistic that we will meet our set target of generating enough income / profits from the first six month of operations and grow the business and our clientele base.

We have been able to critically examine the wheat flour mill production industry and we have analyzed our chances in the industry and we have been able to come up with the following sales forecast. The sales projections are based on information gathered on the field and some assumptions that are peculiar to startups in Springfield – Illinois.

Below are the sales projection for Sammy Jay® Wheat Flour Production Company, it is based on the location of our business and other factors as it relates to small scale and medium scale wheat flour production company start – ups in the United States;

- First Fiscal Year-: $240,000

- Second Fiscal Year-: $450,000

- Third Fiscal Year-: $950,000

N.B : This projection is done based on what is obtainable in the industry and with the assumption that there won’t be any major economic meltdown and there won’t be any major competitor offering same products and customer care services as we do within same location. Please note that the above projection might be lower and at the same time it might be higher.

- Marketing Strategy and Sales Strategy

Before choosing a location for Sammy Jay® Wheat Flour Production Company we conduct a thorough market survey and feasibility studies in order for us to be able to be able to penetrate the available market in our target market locations.

We have detailed information and data that we were able to utilize to structure our business to attract the numbers of customers we want to attract per time and also for our products to favorable compete with other leading wheat flour brands in the United States of America and Canada.

We hired experts who have good understanding of the wheat flour production industry to help us develop In other to continue to be in business and grow, we must continue to sell our well – bagged wheat flour to the available market which is why we will go all out to empower or sales and marketing team to deliver our corporate sales goals.

In summary, Sammy Jay® Wheat Flour Production Company will adopt the following sales and marketing approach to sell our wheat flour;

- Introduce our wheat flour brand by sending introductory letters to residence, wheat flour merchants and other stakeholders in Springfield – Illinois and other cities both in the United States of America and Canada

- Open our wheat flour production company with a party so as to capture the attention of residence who are our first targets

- Engage in road show in targeted communities from time to time to sell our wheat flour

- Advertise our wheat flour in community based newspapers, local TV and radio stations

- List our business and products on yellow pages ads (local directories)

- Leverage on the internet to promote our wheat flour brands

- Engage in direct marketing and sales

- Encourage the use of Word of mouth marketing (referrals)

11. Publicity and Advertising Strategy

In as much as our wheat flour mill is a standard one with well processed and well packaged wheat flour that can favorably compete with other leading brands, we will still go ahead to intensify publicity for all our products and brand. We are going to explore all available means to promote Sammy Jay® Wheat Flour Production Company.

Sammy Jay® Wheat Flour Production Company has a long term plan of distributing our wheat flour in various locations all around the United States of America and Canada which is why we will deliberately build our brand to be well accepted in Springfield – Illinois before venturing out.

As a matter of fact, our publicity and advertising strategy is not solely for selling our products but to also effectively communicate our brand. Here are the platforms we intend leveraging on to promote and advertise Sammy Jay® Wheat Flour Production Company;

- Place adverts on both print (community based newspapers and magazines) and electronic media platforms

- Sponsor relevant community programs

- Leverage on the internet and social media platforms like; Instagram, Facebook , twitter, et al to promote our wheat flour brand

- Install our Billboards on strategic locations all around major cities in the United States of America and Canada

- Engage in road show from time to time in targeted communities

- Distribute our fliers and handbills in target areas

- Position our Flexi Banners at strategic positions in the location where we intend getting customers to start patronizing our products.

- Ensure that our wheat flour bags are well branded and that all our staff members wear our customized clothes, and all our official cars and distribution vans are customized and well branded.

12. Our Pricing Strategy

When it comes to pricing for products such as wheat flour, there are two sides to the coin. We are aware of the pricing trend in the wheat flour mill production industry which is why we have decided to produce various bags – sizes of wheat flour.

In view of that, our prices will conform to what is obtainable in the industry but will ensure that within the first 6 to 12 months our products are sold a little bit below the average prices of various wheat flour brands in the United States of America.

We have put in place business strategies that will help us run on low profits for a period of 6 months; it is a way of encouraging people to buy into our wheat flour brands.

- Payment Options

The payment policy adopted by Sammy Jay® Wheat Flour Production Company is all inclusive because we are quite aware that different customers prefer different payment options as it suits them but at the same time, we will ensure that we abide by the financial rules and regulation of the United States of America.

Here are the payment options that Sammy Jay® Wheat Flour Production Company will make available to her clients;

- Payment via bank transfer

- Payment with cash

- Payment via Point of Sale Machine (POS)

- Payment via online bank transfer

- Payment via check

- Payment via bank draft

In view of the above, we have chosen banking platforms that will enable our client make payment for farm produces purchase without any stress on their part. Our bank account numbers will be made available on our website and promotional materials to clients who may want to deposit cash or make online transfer for the purchase of our products.

13. Startup Expenditure (Budget)

Starting a standard wheat flour mill production company is indeed a capital intensive business. This is so because the amount required setting – up a flour mill is not a piecemeal. The bulk of the start – up capital will be spent on leasing or acquiring a facility and also in purchasing grain milling machines, and packaging equipment.

Aside from that, you are not expected to spend much except for purchase and servicing of distribution trucks, paying of your employees and utility bills. This is the key areas where we will spend our start – up capital;

- The Total Fee for Registering the Business in the United States of America – $750.

- Legal expenses for obtaining licenses and permits as well as the accounting services (software, P.O.S machines and other software) – $1,300.

- Marketing promotion expenses for the grand opening of Sammy Jay® Wheat Flour Production Company in the amount of $3,500 and as well as flyer printing (2,000 flyers at $0.04 per copy) for the total amount of – $3,580.

- Cost for hiring Business Consultant – $2,500.

- Insurance (general liability, workers’ compensation and property casualty) coverage at a total premium – $2,400.

- Cost for payment of rent for 12 month at $1.76 per square feet in the total amount of $105,600.

- Cost for construction of a standard wheat flour mill – $100,000.

- Other start-up expenses including stationery ( $500 ) and phone and utility deposits ( $2,500 ).

- Operational cost for the first 3 months (salaries of employees, payments of bills et al) – $100,000

- The cost for Start-up inventory (raw materials and packaging materials et al) – $80,000

- The cost for counter area equipment (counter top, sink, ice machine, etc.) – $9,500

- Cost for grain milling machines and packaging equipment – $100,000

- Cost for store equipment (cash register, security, ventilation, signage) – $13,750

- Cost of purchase of 3 distribution vans – $30,000

- The cost for the purchase of furniture and gadgets (Computers, Printers, Telephone, Fax Machines, tables and chairs et al) – $4,000.

- The cost of Launching a Website – $600

- The cost for our opening party – $10,000

- Miscellaneous – $10,000

We would need an estimate of $500,000 to successfully set up our wheat flour mill in Springfield – Illinois. Please note that this amount includes the salaries of all the staff for the first 3 month of operation.

Generating Funds / Startup Sammy Jay® Wheat Flour Production Company

Sammy Jay® Wheat Flour Production Company is a family business that is owned and financed by Sammy Jay and his immediate family members. They do not intend to welcome any external business partner which is why he has decided to restrict the sourcing of the start – up capital to 3 major sources. These are the areas we intend generating our start – up capital;

- Generate part of the start – up capital from personal savings and sell of stocks

- Source for soft loans from family members and friends

- Apply for loan from my Bank

N.B: We have been able to generate about $200,000 (Personal savings $150,000 and soft loan from family members $50,000) and we are at the final stages of obtaining a loan facility of $300,000 from our bank. All the papers and document have been signed and submitted, the loan has been approved and any moment from now our account will be credited with the amount.

14. Sustainability and Expansion Strategy

The future of a business lies in the numbers of loyal customers that they have the capacity and competence of the employees, their investment strategy and the business structure. If all of these factors are missing from a business (company), then it won’t be too long before the business close shop.

One of our major goals of starting Sammy Jay® Wheat Flour Production Company is to build a business that will survive off its own cash flow without the need for injecting finance from external sources once the business is officially running.

We know that one of the ways of gaining approval and winning customers over is to retail our well processed and well bagged wheat flour a little bit cheaper than what is obtainable in the market and we are well prepared to survive on lower profit margin for a while.

Sammy Jay® Wheat Flour Production Company will make sure that the right foundation, structures and processes are put in place to ensure that our staff welfare are well taken of. Our company’s corporate culture is designed to drive our business to greater heights and training and retraining of our workforce is at the top burner.

As a matter of fact, profit-sharing arrangement will be made available to all our management staff and it will be based on their performance for a period of three years or more. We know that if that is put in place, we will be able to successfully hire and retain the best hands we can get in the industry; they will be more committed to help us build the business of our dreams.

Check List / Milestone

- Business Name Availability Check : Completed

- Business Registration: Completed

- Opening of Corporate Bank Accounts: Completed

- Securing Point of Sales (POS) Machines: Completed

- Opening Mobile Money Accounts: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Leasing of facility and construction of standard wheat flour mill: In Progress

- Conducting Feasibility Studies: Completed

- Generating capital from family members and friends: Completed

- Applications for Loan from the bank: In Progress

- Writing of business plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents and other relevant Legal Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: In Progress

- Recruitment of employees: In Progress

- Purchase of the Needed furniture, racks, shelves, computers, electronic appliances, office appliances and CCTV: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business both online and around the community: In Progress

- Health and Safety and Fire Safety Arrangement (License): Secured

- Opening party / launching party planning: In Progress

- Establishing business relationship with vendors – wholesale suppliers / merchants: In Progress.

- Website Design & Development Services

- Startup Branding

- Paid Marketing

- Organic Marketing

- Market Research

- Business Plans

- Pitch Decks

- Financial Forecast

- Industry Market Research Reports

- Social Media & Website Guides

- Case Studies

- Services Marketing Website Design & Development Services Startup Branding Paid Marketing Organic Marketing Consulting Market Research Business Plans Pitch Decks Financial Forecast

- About Resources Articles Templates Industry Market Research Reports Social Media & Website Guides Case Studies Team

Wheat Flour Mill Business Plan Template

Explore Options to Get a Business Plan.

Are you interested in starting your own Wheat Flour Mill Business?

Introduction

Global market size, target market, business model, competitive landscape, legal and regulatory requirements, financing options, marketing and sales strategies, operations and logistics, human resources & management.

How To Start Flour Mill Business – Investment, Profit Margin, and Business Plan Explained

Flour Mills are utilized to process staple grains such as Wheat, rice, maize, corn, chickpea, millet, etc., into flour. In the olden day’s flour is processed using manual methods that are tedious and time-consuming work and this is mostly done at home by women.

Today, the processing of flour in homes has drastically decreased. Thanks to advanced technology, the automation of flour processing not only increased the production capacity, but has also saved a lot of time that can be utilized for other uses

Today in countries like India, Pakistan, Nepal, Nigeria , and several Asiatic nations it is easy to find at least one small flour mill business within your vicinity. Not only that, the Flour mill business has created a wealth of opportunity for small-scale business owners and also became a potential source for Women empowerment

There are also schemes such as MUDRA , PMEGP that provide financial support upto 10 Lakhs in setting up of flour mill business

Today, we will understand what is flour mill business, how to start a flour mill business in your vicinity, and discuss the Business plan and profitability aspects

Profitable Flour Mill Business Plan 101

With the continuous growth of the global population and the increasing consumer demand for healthy, nutritious, and diverse food, investing in the flour processing business holds significant potential. From small home-based workshops to large industrial-scale production, investors of varying sizes can find opportunities that suit their needs. Are you aiming to start or grow your flour mill business? Discover essential knowledge on a wide array of flour raw materials—wheat, maize, rice, soybean and more, as well as help you setup your customized commercial flour mill plant.

Purchasing flour milling equipment from ABC Machinery —a professional flour milling machine manufacturer and supplier—can help you set up a low-cost, complete flour milling plant for starting a flour milling business in Nigeria, Kenya, South Africa, Tanzania, Morocco, Egypt, India, Pakistan, Indonesia, the Philippines etc..

Interested in learning more about flour mill business plans for different grains? Check out our other articles in this dedicated section. We cover various flour sources, including wheat, corn/maize, rice, and cassava. Here, our comprehensive guides will analyze the feasibility of your flour mill investment and provide expert advice on selecting the right milling equipment, sourcing high-quality grains, marketing your products, and expanding your customer base.

- Commercial Investment: The Secret of Start a Wheat Flour Mill Business

- Ultimate Guide:Starting a Profitable Cassava Flour Mill Business

- How to start the Best Maize Milling Business Plan

- How to Start Small Rice Mill Business Plan?

Customized Flour Production: Developing a Personalized Flour Mill Business Plan

The success of a flour mill business hinges on multiple factors, with the selection of suitable flour processing equipment being paramount.

When it comes to flour milling equipment, the machines used for milling different types of grains such as wheat, corn, rice, and cassava are indeed specialized and different from one another. Each type of grain has unique characteristics, requiring specific machinery and processes to achieve the best results. Here are the distinctions between the equipment used for milling these different types of flour:

| Aspect |

|

|

|

|

|---|---|---|---|---|

| Wheat Flour Milling | Cleaning, Conditioning | Roller Mills | Conditioning wheat to adjust moisture content | Various grades of flour (bread flour, pastry flour, etc.), bran, germ |

| Corn (Maize) Flour Milling | Cleaning, Degermination | Hammer Mills | Degermination to remove germ and bran | Coarse to fine cornmeal, corn flour, germ, bran |

| Rice Flour Milling | Hulling, Polishing | Stone or Roller Mills | Hulling and polishing to produce white rice before milling into flour | Polished rice, rice flour, bran |

| Cassava (Tapioca) Flour Milling | Chipping, Peeling, Grating, Pressing | Graters, Hammer Mills | Moisture removal through pressing before final grinding | Fine cassava flour (tapioca), cassava pulp |

Key Differents:

Grain Characteristics: The hardness, moisture content, and oil content of the grains differ, influencing the choice of milling machinery.

Processing Steps: Each type of grain requires different preliminary processing steps. For example, rice needs hulling and polishing, while corn requires de-germination.

Finished Product: The desired fineness and quality of the flour vary, requiring different sieving and purification techniques.

While there are some similarities in the basic principles of milling, the equipment and processes are tailored to the specific characteristics of each type of grain. T herefore, selecting the appropriate flour processing machinery is crucial for your milling project and customized flour mill business plan. To learn more about starting a profitable milling business, click the consultation button below to request a free flour mill business proposal!

Feasibility Analysis for Starting Grain Milling Business

Invest a Cost-effective Flour Milling Factory

The success of a flour mill business is influenced by various factors, including the strength of the business plan, efficiency in controlling production costs, and the implementation of effective market strategies.

Flour Milling Market Potential and Strategic Planning

For entrepreneurs considering the launch of a wheat or maize milling venture, a comprehensive market analysis within the business plan is important. Here are 2 typical cases:

Corn/maize Flour Business in Africa

Due to population growth and urbanization, the demand for maize in Africa is projected to increase by 2.5% annually. This expanding demand offers significant opportunities for new entrants in the maize milling sector.

Wheat Flour Business in India

Similarly, the wheat flour market shows immense potential. In India , driven by increased consumption of bakery products and rising health consciousness, t he wheat flour market is expected to grow at a CAGR of 4.5% from 2020 to 2025 .

Tailoring Business Plans to Local Markets

In Uganda: maize flour is a staple in Ugandan cuisine , making the local market highly receptive to high-quality maize flour products. Catering to local tastes and preferences can significantly enhance market penetration and business success.

In India: For those aiming to set up a wheat flour production operation in India, understanding local consumption patterns is vital. Indian consumers favor whole wheat flour (atta) for making traditional bread (chapati). By comprehending these market dynamics and adjusting product offerings accordingly, businesses can capture a substantial market share.

Balancing Flour Milling Production Costs and Operational Efficiency

The expenses involved in establishing a milling plant can vary widely based on the scale of the operation and the type of machinery employed. A detailed flour production business plan should outline the entire process from raw material procurement to final product sales , including how technological innovations can reduce costs and improve product quality. Automated milling systems can lower labor expenses and increase productivity, while quality control systems ensure that the flour meets market standards.

With over 20 years of experience in the flour mill industry, ABC Machinery has become a leading supplier of turnkey flour milling projects, providing customers with high-quality machines, installation and commissioning services, and after-sales support. Whether you need a small-scale mill or a large commercial operation, we have the expertise and equipment to meet your needs. Contact us today for a free consultation and let us help you get started on your flour mill business journey!

- Single Flour Milling Machine

- Small Scale Flour Mill

- Grain Cleaning Equipment

- Flour Milling Equipment

- Auxiliary Machines

- Storage Silos

- Pneumatic Grain Conveyor

- How to Profitably Start a Flour Mill Business in Nigeria?

- How to Start a Flour Milling Plant Business in Pakistan?

- Characteristics And Application of Soy Protein Isolate

- Small Maize / Corn Flour Mill Machinery Design and Layout

- How to Choose a Reliable Small Wheat Grinding Machine Sale?

- How to Set Up Your Own Mini Wheat Flour Milling Plants at Home?

- Soy Protein Isolation Production Line Cost

- Cost of Setting Up A Soybean Isolate Protein Plant

- How to Maintain Your Own Home Flour Mill Equipment

- How to Make Maize Flour at Home

- Start Business

- Grow Business

How to Start a Flour Mill Business – Complete Guide

- by Next What Business Research Team

- Agro Based , Business Plans , Food

- August 30, 2024

A flour mill is an easy business to start. You can start this business in both city and rural areas. Furthermore, a flour mill offers a wide range of manufacturing opportunities for entrepreneurs.

Table of Contents

What is a Flour Mill Business?

A flour mill business involves the processing of wheat and other grains to produce flour, a fundamental ingredient in various food products. The primary objective of a flour mill is to transform raw wheat kernels into flour through milling processes.

How a Flour Mill Works

Here are key aspects of a flour mill business:

Raw Material Processing

Flour mills source raw materials, mainly wheat, from agricultural regions. The quality of wheat is crucial for producing high-quality flour. The Milling Process starts with the cleaning and conditioning of Raw wheat. It undergoes cleaning to remove impurities and conditioning to optimize moisture content.

Milling Machines

The cleaned wheat is then milled using specialized machinery to separate the bran, germ, and endosperm. This process results in different types of flour, including whole wheat flour and refined flour. Flour mills implement quality control measures by conducting laboratory tests on the flour produced. This includes assessments of protein content, moisture levels, and other factors.

Packaging and Distribution

Packaging: The processed flour is packaged in various quantities, from small consumer packages to bulk packaging for industrial clients. Flour mills distribute their products through various channels, including wholesalers, retailers, and, in some cases, directly to consumers.

Market Segmentation

Flour mills may produce different varieties of flour, such as all-purpose flour, whole wheat flour, speciality flour, and even organic or gluten-free options. It caters to diverse markets, including households, bakeries, food manufacturers, and industrial users.

Regulatory Compliance

Flour mills must comply with local and national regulations related to food safety and quality. This involves obtaining the necessary licenses and certifications. Maintaining high hygiene standards throughout the milling process is essential for regulatory compliance.

Technological Innovation

Flour mills often invest in advanced milling machinery to improve efficiency and product quality. Some mills incorporate automation to streamline processes and reduce labour requirements.

Business Models

Flour mills may adopt various business models, such as traditional milling, speciality flour production, organic flour milling, or industrial-scale milling.

Market Trends

Adaptation: Flour mills monitor market trends and adapt their processes to meet changing consumer preferences. This may include producing gluten-free products or emphasizing sustainable and organic practices.

Supply Chain Management

Flour mills establish reliable supply chains for wheat, often collaborating with farmers or agricultural cooperatives. Efficient logistics are crucial for timely sourcing of raw materials and distribution of finished products.

Is the Flour Business Profitable

Flour remains a staple in various food products, contributing to consistent consumer demand. Data from market research indicates sustained consumer interest in home baking and cooking, driving flour consumption. According to a report by Statista, the global flour market was valued at approximately $245 billion in 2020. The market is projected to witness a compound annual growth rate (CAGR) of around 3.7% from 2021 to 2028.

15 Steps to Start a Flour Mill Business

Starting a flour mill business can be a rewarding venture, providing a staple product that is in constant demand. Here’s a step-by-step guide to help you navigate the process of establishing a successful flour milling business:

1. Conduct Market Research

Identify the target market by determining the demand for flour in your target market. Consider factors such as population size, dietary habits, and the presence of competitors.

2. Select your Niche

Below we list down the Most Profitable Flour Mill Business Ideas:

- Bran: The bran is the skin of the grains. Also, bran is used as a dietary fibre.

- Cornflour: Cornflour is an essential item in the food processing industry. Corn milling or maize milling is a highly profitable business. However, you must establish the mill in a location where you can source the corn easily.

- Gram Flour: The most common name for gram flour is besan. And the product has a great demand in our country.

- Sooji: Sooji is another trendy grocery item in our country. You can produce sooji from the same manufacturing unit.

- Wheat Flour (Atta): Atta is one of the most essential items for the domestic kitchen.

- Wheat Flour (Maida): Maida has comparatively more demand than atta.

3. Select the Business Model

The business models of flour mills can vary based on factors such as scale, target market, and value proposition. Here are several common business models adopted by flour mills:

⇒ Traditional Flour Milling Model

Traditional flour mills follow a conventional model of sourcing wheat, milling it into flour, and distributing the product to local markets.

⇒ Specialty Flour Milling Model

Speciality flour mills focus on producing unique and high-quality flours tailored to specific consumer preferences or dietary requirements.

⇒ Organic Flour Milling Model

Organic flour mills exclusively source and process organic wheat, catering to the growing demand for organic and sustainable food products.

⇒ Industrial Flour Milling Model

Industrial flour mills operate on a large scale, producing massive quantities of flour for commercial and industrial use.

⇒ Vertical Integration Model

Flour mills employing vertical integration control various stages of the supply chain, from wheat cultivation to retail distribution.

⇒ Direct-to-Consumer Model

Flour mills adopting a direct-to-consumer model sell their products directly to end consumers through online platforms, farmer’s markets, or on-site stores.

⇒ Contract Milling Model

Contract milling involves milling wheat on behalf of other businesses, allowing them to focus on their core activities.

⇒ Export-Oriented Model

Flour mills following this model focus on exporting their products to international markets, capitalizing on global demand.

⇒ Cooperative Flour Milling Model

Cooperative flour mills are owned and operated by a group of farmers or community members who share in the management and profits.

Read: Home Based Manufacturing Business Ideas

4. Create a Business Plan

Clearly outline your business goals, including the scale of production, target market, and financial projections. Conduct a thorough cost analysis covering equipment, raw materials, labour, and operational expenses.

5. Choose a Suitable Location

Select a location close to wheat-producing regions to minimize transportation costs. Ensure access to essential infrastructure, including water and electricity.

6. Obtain Necessary Licenses and Permits:

You need to understand and comply with local and national regulations governing flour milling. Obtain the necessary licenses and permits required to operate a flour mill.

Here we put a list of basic requirements.

- First of all, determine the form of the organization and register your business with ROC.

- Apply for the Trade License from the local municipal authority.

- Furthermore, apply for Udyog Aadhaar MSME Online Registration

- Apply for FSSAI registration.

- You have to apply for AGMARK .

- Apply for BIS certification

- Check the tax liabilities.

- This business doesn’t demand any pollution clearance. However, check it with the State Pollution Control Board of your area.

- Apply for the GST registration number.

7. Secure Funding

Determine the initial investment required for land, equipment, and working capital. Consider loans, grants, or partnerships to secure the necessary funds.

8. Flour Mill Business Plant Setup & Machinery

First of all, you have to secure a location for manufacturing operations. Check the available transportation facility, electricity, water, semi-skilled manpower, and drainage facility. For setting up a small-scale unit with the entire product range, you will need to have 3000 Sq Ft built-up areas at least.

Related: Things To Consider in Selecting Factory Location

Here are some basic requirements for plant & machinery:

- Bucket elevator

- Reel machine (3 segments)

- Rotary separator with aspiration channel

- Scourer machine with aspiration channel

- Intensive dampener

- Indent cylinder

- Screw conveyor

- V-Groove, Pulleys, Couplings, V-Belts, etc

- Weighing scale

- Dust cyclone

- L.P fan for cleaning

- Roller Mill body

- Roll Grooving & spindle cutting

- Supper cyclone

9. Set Up the Milling Unit

Design an efficient layout for the milling unit, considering workflow and safety. Set up and install the milling equipment, ensuring proper calibration and maintenance.

10. Quality Control Measures

Implement regular testing procedures to ensure the quality of the flour produced. Adhere to strict hygiene standards in the milling process to meet regulatory requirements.

11. Employ Skilled Workforce

Hire experienced millers for operating machinery, quality control, and overall production management. Conduct training programs to enhance the skills of your workforce.

12. Develop Distribution Channels

Build relationships with distributors, wholesalers, and retailers for efficient distribution. Consider export options to expand your market reach.

13. Implement Marketing Strategies

Develop a strong brand identity for your flour. Highlight any unique qualities or milling processes. Utilize online platforms to create awareness and reach a wider audience.

14. Monitor Wheat Market Trends

Keep abreast of wheat market trends, including price fluctuations and supply-demand dynamics. Implement strategies to manage risks associated with market volatility.

15. Build Relationships with Suppliers

Negotiate favourable contracts with wheat suppliers to ensure a steady and cost-effective supply. Work closely with suppliers to maintain consistent quality standards.

Related: Questions To Ask Before Starting a Manufacturing Business

Frequently Asked Questions

What is the cost of setting up a flour mill.

The flour milling business generally demands two different types of investments. One is a fixed capital investment. It includes land (if you purchase the land), building, machinery, registration, and licensing fees. If you start the business with a rental premise then fixed capital includes the security deposit amount for the area of land.

Another is the working capital investment. It includes raw materials, staffing, rent, transportation, marketing, distribution, and administration costs. There are different types of small business loan-providing companies in our country. Loan providers also offer various customized schemes for your specific requirements.

Related: Best Small Business Loans in India

4. What is the profit margin of flour mills?

You can earn an inspiring profit margin from a flour milling business. However, the percentage of profit depends on several aspects. To enhance the profit, you will need to reduce the production cost.

Also, you must consider enhancing the sales volume and penetrating new areas. Remember, you will only expect a good profit when you sell the product as a brand.

What Types of Flour Can Be Produced by a Flour Mill?

Flour mills can produce various types of flour, including all-purpose flour, whole wheat flour, speciality flour (such as gluten-free or organic), and customized blends based on consumer preferences.

What are the Key Factors Influencing Flour Business Profitability?

Key factors include market demand, product diversification, operational efficiency, raw material costs, and adherence to quality and safety standards.

What are the Market Trends in the Flour Industry?

Market trends include increased demand for speciality and organic flour, the rise of e-commerce and direct-to-consumer sales, and a focus on healthier flour options.

Can Flour Mills Export Their Products?

Yes, flour mills often explore export opportunities. Understanding international trade regulations, market demand, and quality standards is essential for successful exports.

What Certifications are Important for Flour Mills?

Answer: Certifications such as ISO 9001 (Quality Management), ISO 22000 (Food Safety Management), and relevant organic certifications contribute to ensuring quality and compliance with industry standards.

What Challenges Might Flour Mill Businesses Face?

Challenges can include fluctuating raw material costs, market competition, regulatory changes, and the need for ongoing investments in technology and quality control.

Discover more from NextWhatBusiness

Subscribe to get the latest posts sent to your email.

Type your email…

Flour Mill Business Plan: Key Cost Factors You Need to Consider

Although there are many flour milling plants in the market, but the high demand for various flours makes it still profitable to start flour milling business through setting up small scale or medium scale flour mill factory.

Many people are interested in starting flour mill business. However, they have no ideas about the detailed steps and perspective cost of flour mill factory setup. And they are also curious about how much money can a flour mill, like a small scale, make per year . Here, ABC Machinery offers the information you may be needed, like wheat flour mill business plan. (You may also like: Flour Mill Plant Cost >>)

Flour Milling Business Types

Generally, flour milling business has two types small scale or large scale. Choosing small scale or large scale should fully take your specific conditions into consideration. Here we will analyze the small scale flour mill and large scale flour mill plant for your consideration.

Flour Mill Machine for Small Business

Firstly, the small scale flour mill machinery requires small amount of money, but the profit margin is relatively small. It works greatly in two models, one is to charge a certain amount for milling grains, the other is to produce flour mill. So, small scale flour mill business is flexible, you can adjust your production based on the market needs. In addition, the whole operations are relatively easy and simple, so almost all the adult can use it.

Large Scale Flour Mill Plant

It is inevitable that large scale flour mill project requires heavy investment since the complicated flour milling process and advanced flour milling machinery. However, the profits are decent in most cases since there are large demand of wheat flour around the world, especially in some regions, such as India, Egypt, Algeria, Italy, Brazil, etc. Large scale flour mill plant can achieve automatic and continuous flour production, from raw materials to packaged flour.

| Some of Our Successful Flour Milling Projects | ||

|---|---|---|

| Wheat | 80TPD | Ethiopia |

| Wheat | 60TPD | Algeria |

| Maize | 50TPD | Zambia |

| Wheat | 40TPD | Ethiopia |

| Wheat | 30TPD | Chile |

| Maize | 30TPD | Uganda |

| Maize | 20TPD | India |

| Wheat | 20TPD | Rumania |

| to get project cost, process design, equipment layout details! | ||

Cost of Setting up Flour Mill Factory

The cost for a flour mill factory varies a lot due to the different production capacity. If you are going to set up a small scale factory flour mill, the cost will be a much cheaper than medium scale or large scale flour mill plant. Setting up flour mill plant may require large amount, so if you doesn’t have enough money but won’t want miss the profitable endeavors, you can search helps of bank loans or just to find out a reliable partner who is also enthusiastic about the flour milling business.

Typically, the F6FC mini flour mill machine will cost $2,500 ~ $3,000 . The M6FX mini flour mill factory will cost $3,500 ~ $5,000 . However, for the large scale flour mill factory, the cost definitely high. For example, the large scale flour mill plant equiped with automatic wheat mill machinery may cost $19,000 ~ $1,448,000 . But, this price is just for a references, the exact cos of the flour mill factory plant should based on the exact conditions and equipment selections!

M6FX Mini Flour Mill Machine Working Video

If you are interested in starting your own wheat/atta flour mill business, or other grain flour business, like cassava flour milling, please contact us for FREE quotation on both small scale or large scale flour mill machinery.

Custom-made Flour Mill Business Plan

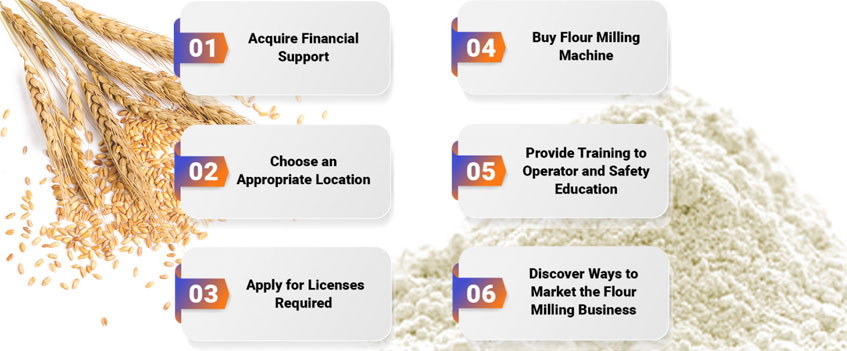

- Get Financial Support

Any business will need financial support before starting. How much money is required to have the flour milling machine ? Is it needed to take out loans or just put all your money into this business. For the estimate amount, it is better to have a better understanding about local market as well as global market of profit in flour mill business. (Read more: Get the Policy Loan for Your Business >>)

- Find Right Factory Location

A right factory location is very important for the flour milling business. The right factory location should have convenient transportation that is easily for the access of raw materials and delivery and shipping of final packed flour. After the location is decided, it it time to get out the covering area of the flour processing plant . In general, a complete flour mill plant layout should include the area for storage of raw materials , area for flour milling machines , area for flour packaging .

- Get Licence for Flour Milling

Getting the licence from the government or registering your factory in local administration is also important for the success of the flour milling business . It is the basic requirements for a flour milling factory to ensure every policy and flour production process are compliant with the local regulation and legislation.

- Purchase Flour Milling Machine

When above mentioned conditions are ready, it is time to think about how and where to get the flour milling machinery . The selection of flour milling machines are closely connected with the capacity, the investment cost, the flour milling process, the raw materials and more . Therefore, it can’t be done overnight. It needs to take time to choose the most reliable flour milling machinery supplier, which can help to avoid many unexpected problems in the installation and operation of the flour milling factory and lower the cost of machinery purchases. (Read more: Wheat Flour Machine Suppliers >>)

- Operator Training and Safety Education

For most flour mill factory, there should be have several operators or workers for flour production . The systematic training and safety education for the workers and operators are very important one the flour mill factory starts running . They not only should to have a good command of the equipment and machinery, but also need to know how to flour ingredients additions. Most four mill machinery supplier will offer the training plan and course for their customers to help them quickly enters the flour industry and avoid many typical operational mistakes.

- Make Marketing Strategy for flour Milling Business

How to make the final produced flour to the direct customers is also a hard task for flour milling factory investors. If the competition of local flour market is low, then don’t worry, the selling of final flour products will be very good. Some markets, such Nigeria, India, Pakistan, Uganda, Chile, Australia, Algeria, Ethiopia and more, are very hot for start flour milling business since the high demand and low competition. (Read more: Flour Mill Project Built by ABC Machinery >>)

When you are going to start flour mill business by setting up a flour mill factory, you can have a reference of the above mentioned tips and steps for a complete and viable flour milling business plan. ABC Machinery can offer custom-made flour mill business plan to easily get start flour milling business. If you still have many confusions, please just contact us for more detailed information, we have built many flour mill projects all over the world. We do believe, some of our experiences are what you want!

- Can oats be ground into flour? With a particle size of 40-50 mesh, what is the extraction rate?

Yes, oats can be ground into flour. The extraction rate may vary depending on the specific process and the customer's requirements. If the oats are steam-cooked and dried before grinding, or if they are directly ground without any additional processing, the resulting flour may have a coarse texture. If the quality requirements are not very high, the extraction rate can reach around 85%.

- Can one M6FC flour mill machine handle both wheat and rice?

Yes, the M6FC flour mill machine can process both wheat and rice. The particle sizes of wheat and rice are similar, so there is no need to adjust the parameters of the milling machine. Simply grind and sift to obtain the flour. For wheat, you can add a cleaning device, but it is not necessary for rice. You can directly feed the rice into the storage hopper for grinding.

- Grain Cleaning & Hulling

- Flour Milling

- Starch Processing

- 10~30 ton/day Wheat Flour Mill

- 30~60 ton/day Wheat Flour Mill

- 60~150 ton/day Wheat Flour Mill

- 150~300 ton/day Wheat Flour Mill

- 300~1000 ton/day Wheat Flour Mill

- Flour Mill Machinery Pakistan

- 20TPD Maize Milling Plant Shipped to Uganda

- Commercial Maize Milling Machine Price in Kenya| Low Cost Processing

- Customized Maize Flour Processing Plant by ABC Machinery

- Business Ideas

- Startup Plans

- Advertising

How To Start Flour Mill Business [PLAN]

- by Olaoluwa

- March 23, 2023 August 28, 2024

FLOUR MILL BUSINESS STARTUP GUIDE

If you have been worried about how to start a flour mill business, then you are warmly welcomed. I am ready to take your hands and show you how well you can do it. But wait for a moment, have you ever asked yourself these questions?

One, is the flour mill business lucrative? Two, is the demand for flour that high? And lastly, are the raw materials to produce the flowers readily available?

It might interest you to know that ‘yes’ is the answer to all these questions!

However, you might ask? Why do I have to find answers to these questions? The answer is simple. Positive or negative answers to these questions will either stimulate your arousal or kill the passion to start a flour mill business.

Scan through what happens all around you with the daily demand and usage of flour. Bakery, food processing and pharmaceutical companies are the largest consumers of flour and we get to see their end product each passing day.

Not exempting the local use in your vicinity for pastry as well.

Additionally, the raw materials for the production of flowers which could either be corn, wheat or millet are readily available. All these gives a high demand for flour and promise a high Return on Investment (ROI).

The next step is knowing what how to start a flour mill. Although there is a caution. The steps might seem similar to any steps for beginning a business, but the processes involved are quite different. Therefore, do not quickly dismiss that you have known a point and thus jump to other. Read carefully!

Steps Involved in Starting a Flour Mill Business

- Get Trained to Handle Factory Machinery or Equipment

If you are a newbie with zero knowledge about how the machines works in the factory, then you should not take this step with levity. You must have a solid foundation.

If your case is a lot different, possibly you have handled or worked at a flour mill company before, you will still need to get acquainted with the machines. There might be new development you have not heard of. Yearn to have basic training on the grinding process in achieving the final product.

To accomplish this will demand that you make visit to flour mill companies so you can be trained. There is an opportunity to make research on the Internet to boost your experience on effective machines you can use and how to handle them.

- Register Your Flour Mill Business

There is no hard and play rule here. Get your business registered. Seek help from the local authority in your location or the location where you intend to choose on how you can register your business. You will earn real freedom and operate your business like a king.

- Write a Flour Business Plan

Your flour mill startup plan is not limited to the size of the business you are operating. Therefore, it is a must to write a decent and well explanatory plan if you want to start a flour mill business. If you will need loan to fund your business, you must write a catchy business plan so as to attract investors.

- Acquire a Location

You might have to rent or buy a space for your flour mill industry. Getting a location for the business is a must. That is where you will have your machinery installed and the company’s office.

The size of the location primarily will be influenced by the size of machines you are to run and the number of workers to employ. It is also important to bear in mind that the location of the flour mill industry should be easily located by customers and easy delivery of raw materials for the production of flours.

- Buy Flour Mill Machinery and Raw Materials

The space you have acquired for your business would not function without the installation of machines and buying of raw materials to start the flour mill. It is then required that you buy the machines you have surveyed during your training and visit cost effective locations to buy the machines. If you lack fund, you can rent but make it a goal to buy as soon as possible.

Getting raw materials does not require an extensive search. You can contact Companies that stores grains in large quantities for sale.

Also, you can meet mechanized farmers too who stores grains at large quantities majorly for commercial purpose.

- Source for Customers

Every business products needs customers, and your flour mill business is not an exemption. Endeavour to get customers and retain a solid relationship with them. Write companies and inform them about your flour mill company.

Keep to whatever promise you will make. Be optimistic that as your business grows, you will get more customers.

- Keep On Improving

This final phase is not the final stage to start a flour mill business operation. Constantly, you will need to keep improving your products, customer’s relation, modes of advertisement and utilizing new technological equipment.

Have good relationship with your employees and maintain an honest dealing with them. If you try all possible best to keep on improving, you will succeed on the quest to start a flour mill business.

I am well convinced that if these points are applied correctly, you will start a flour mill that will be profitable and at the same time gain the approval of most companies that will be buying your final products.

FLOUR MILL BUSINESS PLAN EXAMPLE

Here is how to start a flour mill.

I will go straight to the point that is, the BUSINESS STARTUP GUIDE because it is expected that you already know the basics of the business, the requirements and skills since you are about to start it.

BUSINESS NAME: Sammy Jay Wheat Flour Production Company

Executive Summary

Business Overview

Product Offering

Vision Statement

Mission Statement

Business Structure

Target Market

Sales Forecast

Sammy Jay Wheat Flour Production Company is a standard and licensed wheat flour mill production company that will be located in an industrial area, Springfield-Illinois. We have secured a long term lease of the facility in this area which is close to a wheat farm and there is an option of renewal of the lease on agreed terms and conditions which seems favorable to us.

It has been approved by the government to use the facility for this type of business and the facility has easy accessibility and easy movement of raw materials and finished products.

Sammy Jay Wheat Flour Production Company is a business that will engage in processing, packaging and retailing wheat flour. We are in the business to give well packaged wheat flour to customers so they can have the value of their money as well as to make profits.

Feasibility studies and market surveys has been done to find the most suitable location for our business due to the fact that there are several wheat flour mill companies scattered all around the United States and Canada.

Plans have been made to have a wide distribution network for wholesalers in Illinois and the United States.

Apart from producing healthy and well packaged wheat flour, our greatest concern is customers’ care because we know that they are the ones keeping us in business and they are determinants of the success or otherwise of the business. We are ready to go extra miles in satisfying our customers so they can become loyal customers to our business.

There is a CRM software that will make it possible to have a one on one relationship with our customers and also involve our customers when making decisions that directly or indirectly affect them.

Sammy Jay Wheat Flour Production Company is a family business that is owned and managed by Sammy Jay and the immediate family. He is a graduate of micro biology (B. Sc) and also has a Master’s degree in Business Management.