Brought to you by:

Walmart: Supply Chain Management

By: P. Fraser Johnson, Ken Mark

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to…

- Length: 16 page(s)

- Publication Date: Jul 8, 2019

- Discipline: Operations Management

- Product #: W19317-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to compare Walmart's source of competitiveness with those of other retailers-both online including Amazon.com and traditional brick-and-mortar retailers, such as Target-to develop insights into the management of a large, complex, global supply chain network. As competition between Walmart and its online and offline competitors heated up, a key challenge for the company's president and chief executive officer was deciding what changes made to Walmart's expanding supply chain would best support its strategic objectives. What supply chain capabilities would Walmart need as its business model continued to evolve?

Learning Objectives

This case can be used in an undergraduate or MBA course in supply chain management, operations management, business strategy, international business, logistics, purchasing, or marketing. It can provide an introduction to supply chain management using a company with which most students are familiar. In doing so, it allows students to learn how Walmart has built up its supply chain capabilities over the past five decades, and how the company leveraged these capabilities to become the world's largest retailer. Combining the Walmart case with the "Amazon.com: Supply Chain Management" case (W18451) in back-to-back classes provides a powerful illustration of the differences between two leading companies and demonstrates the importance of alignment of supply chain competencies with organizational strategy. After completion of this case, students will be able to: Assess Walmart's supply chain and identify its key competitive advantages. Quantify Walmart's ability to generate value from its supply chain. Identify potential opportunities and challenges for Walmart to improve its supply chain. Analyze the effects of the opportunities and challenges facing Walmart on its growth and evolution.

Jul 8, 2019 (Revised: Sep 9, 2019)

Discipline:

Operations Management

Geographies:

United States

Industries:

Retail trade

Ivey Publishing

W19317-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

- Automation Supply Chain

- Continuous Improvement

- Last Mile \ Delivery

- Logistics Training and Resources

- Manufacturing

- Procurement/Negotiations

- Supply Chain

- Warehouse/Fulfillment

- Artificial Intelligence

- Entrepreneur

- Robots & Drones

- Self-Driving Vehicles

- *SCM Social Media Channels

- SCT Discussion

WALMART SUPPLY CHAIN BEST PRACTICES | MBA CASE STUDY

Let’s take a look at Walmart Supply Chain best practices. Walmart has one of the most sophisticated and efficient supply chains in the world. It has been constantly evolving since the company was founded in 1962.

In the early days, Walmart’s supply chain was relatively simple. The company would order goods from manufacturers and then ship them directly to its stores. However, as Walmart grew, its supply chain became more complex. The company began to work with more suppliers and to move goods around the world.

In the 1980s, Walmart began to invest heavily in technology to improve its supply chain. The company implemented a computer system that allowed it to track inventory levels and forecast demand. It also began to use radio frequency identification (RFID) tags to track the movement of goods.

These investments helped Walmart to improve the efficiency of its supply chain. The company was able to reduce costs, improve accuracy, and speed up the delivery of goods to its stores.

Walmart Today

Today, Walmart’s supply chain is a global network that spans over 10,500 stores in 24 countries. The company works with over 100,000 suppliers and moves billions of products each year.

Walmart’s supply chain is still evolving. The company is constantly looking for ways to improve efficiency and sustainability. It is also investing in new technologies, such as artificial intelligence and blockchain, to further streamline its operations.

Walmart’s supply chain is a major competitive advantage. It allows the company to offer low prices and a wide selection of products to its customers. It also helps Walmart to respond quickly to changes in demand.

Here are some of the key factors that have contributed to the success of Walmart’s supply chain:

- Centralization: Walmart has centralized its supply chain operations. This has allowed the company to improve efficiency and coordination.

- Technology: Walmart has invested heavily in technology to improve its supply chain. This includes the use of RFID tags, computer systems, and big data analytics.

- Collaboration: Walmart works closely with its suppliers to improve the efficiency of its supply chain. This includes sharing data and working together to solve problems.

- Sustainability: Walmart is committed to sustainability. This is reflected in its supply chain, where the company is working to reduce waste and emissions.

Walmart’s supply chain is a complex and ever-evolving system. However, the company’s commitment to efficiency, collaboration, and sustainability has helped it to create one of the most successful supply chains in the world.

Walmart and P&G Partnering

Walmart and P&G partnered to make a breakthrough in supply chain by sharing data and collaborating on new technologies.

In the late 1980s, Walmart was struggling to keep up with demand. The company was growing rapidly, and its supply chain was not able to keep pace. P&G, on the other hand, was having difficulty getting its products onto Walmart’s shelves.

The two companies decided to partner to find a solution. They began by sharing data about inventory levels and customer demand. This allowed them to better coordinate their supply chains and ensure that the right products were in the right place at the right time.

Walmart and P&G also worked together to develop new technologies to improve their supply chain efficiency. For example, they developed a system called Continuous Replenishment Program (CRP). CRP uses real-time inventory data to automatically trigger shipments of products from P&G to Walmart stores.

This partnership has been a huge success for both companies. Walmart has been able to improve its customer service and reduce costs. P&G has been able to increase sales and improve its profitability.

Here are some of the specific benefits that Walmart and P&G have gained from their partnership:

- Reduced inventory levels

- Increased sales

- Improved customer service

- Reduced costs

- Improved profitability

The partnership between Walmart and P&G is a model for how companies can work together to improve their supply chains. By sharing data and collaborating on new technologies, companies can create a more efficient and effective supply chain that benefits everyone involved.

Walmart and Retail Learning Resources

- 5 Amazing Warehouse Robots for Fulfilment and Distribution Centers.

- Amazon Drone Delivery in California. It’s Happening.

- Amazon Reveals Warehouse Robots For Sorting Packages and Fully Autonomous Mobile Robot.

- How Amazon’s Supply Chain Management Strategy Works?

- How Walmart Is Betting Big On Stores To Catch Amazon In E-commerce.

- How Walmart will use autonomous driverless delivery to boost online sales.

- Sam Walton and Jeff Bezos Leadership and Supply Chain Quotes.

- Skirting Supply Chain Chaos – Amazon.

- Supply Chain Quotes: Take it to the next level.

- Understand Lean and Agile Supply Chain strategies.

- Walmart CEO Doug McMillon Quotes .

- Why Use an Agile Supply Chain Strategy?

Automated Distribution Center Simulation

Why Free Shipping Isn’t Free – FedEx, UPS and Amazon.

What Retailers Like Amazon Do With Unsold Inventory

Tested Walmart, Target and Amazon’s Delivery Speeds.

The Amazon Fast Shipping System.

An army of autonomous robots works inside a warehouse

Leave a comment cancel reply.

You must be logged in to post a comment.

Walmart: Supply Chain Management

About This Product

This operations management case study focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company’s supply chain network and capabilities. Data in the case allows students to compare Walmart’s source of competitiveness with those of other retailers—both online including Amazon and traditional brick–and-mortar retailers, such as Target—to develop insights into the management of a large, complex, global supply chain network. As competition between Walmart and its online and offline competitors heated up, a key challenge for the company’s president and chief executive officer was deciding what changes made to Walmart’s expanding supply chain would best support its strategic objectives. What supply chain capabilities would Walmart need as its business model continued to evolve?

Learning Objectives

This Walmart Supply Chain Management case study can be used in an undergraduate or MBA course in:

- Supply chain management

- Operations management

- Business strategy

- International business

It can provide an introduction to supply chain management using a company with which most students are familiar. In doing so, it allows students to learn how Walmart has built up its supply chain capabilities over the past five decades, and how the company leveraged these capabilities to become the world’s largest retailer. Combining the Walmart case with the Amazon.com: Supply Chain Management case in back-to-back classes provides a powerful illustration of the differences between two leading companies and demonstrates the importance of alignment of supply chain competencies with organizational strategy.

After Completion of This Case Students Will Be Able To:

- Assess Walmart’s supply chain and identify its key competitive advantages.

- Quantify Walmart’s ability to generate value from its supply chain.

- Identify potential opportunities and challenges for Walmart to improve its supply chain.

- Analyze the effects of the opportunities and challenges facing Walmart on its growth and evolution.

- Additional Details

- Supplemental Products

- Supporting Materials

The marketplace for case solutions.

Half a Century of Supply Chain Management at Wal-Mart – Case Solution

This "Half a Century of Supply Chain Management at Wal-Mart" case study looks at Wal-Mart, which is known as the world's largest retailer. It focuses on the company's strategies which seemed to be not so effective in the past years as its competitors have come too close to them.

P. Fraser Johnson and Ken Mark Harvard Business Review ( W12894-PDF-ENG ) April 19, 2012

Case questions answered:

- As James Neuhausen, what is your analysis of Wal-Mart’s supply chain management? Are the company’s supply chain capabilities still a source of competitive advantage? Why or why not?

- How is Wal-Mart doing? How does it compare to its competitors?

- As Johnnie Dobbs, Wal-Mart’s Executive Vice-President (EVP) of Logistics, where would you spend your money or focus your energy?

- As Johnnie Dobbs, what recommendations would you make to the Chief Executive Officer (CEO)?

- Where do you see the opportunities for Wal-Mart in its global supply chain?

- How does Wal-Mart’s supply chain compare with Apple’s supply chain? How are they different, and how are they similar?

Not the questions you were looking for? Submit your own questions & get answers .

Half a Century of Supply Chain Management at Wal-Mart Case Answers

1. as james neuhausen, what is your analysis of wal-mart’s supply chain management are the company’s supply chain capabilities still a source of competitive advantage why or why not.

As James Neuhausen, I think Wal-Mart’s supply chain management helps it attain various competitive advantages. According to Statista, Walmart is the largest retailer and discount store globally, with net sales of U.S. $520 billion (Statista, 2020).

As we all know, now the competition is among the supply chains rather than the main businesses. Therefore, Walmart was more focused on the supply chain from the beginning to get profits by applying its everyday low-price strategy.

For this, from the beginning, Walton tried to reduce the operating costs and investment of Walmart. Walmart’s supply chain is a strong point, and with time, it has adopted various strategic methods to improve its supply chain and follow its low-price strategy (Lu, 2018).

Moreover, the U.S. famous retailer Wal-Mart’s supply chain has helped it earn a competitive advantage in the retail market. Also, it allows them to attain their mission and vision statements.

The main reason behind Walmart’s success is the collaboration and combined efforts of the partners, suppliers, customers, and management. Along with all the stakeholders’ participation, the various supply chain factors help the company gain a competitive advantage (Mark, 2012).

Some of the leading supply chain capabilities that support Wal-Mart in gaining a competitive advantage in the retail market are:

- Walmart made excellent and long-term relations with suppliers. Also, it made the communication process easy to improve the flow of products by reducing their inventory level. Moreover, they try to use global merchandising centers to purchase bulk items to get lower prices (Lu, 2018).

- Initially, they removed the intermediates who helped them to purchase the items. By doing this, they have reduced some of their expenditure (Mark, 2012).

- They are also using the vendor-management inventory to give the suppliers the responsibility to manage their products. This initiative’s advantage is that the stores would get almost full inventory after some time (Mark, 2012).

- Walmart is also using the cross-docking strategy. By applying this strategy, there is no need to store the items in between the way. However, they directly transfer the products from one truck to another truck. When they move the products to the company’s truck to deliver to stores, they change the packaging and put the tags within 24 hours. This helps to save the cost of transportation and inventory and also to save transportation time (Lu, 2018).

- Moreover, when they cross-docked the products, the company sent their black haul products back to the suppliers. Black hauls are unsold products. They can save some of the cost and use the backward integration method (Mark, 2012).

- Walmart was the first company to use UPCs for transactions. After that, they invested a lot in integrated technology to improve their supply chain and inventory. For this, they have implemented the retail link, a database connected with the global satellite system. There are various benefits of this database that help forecast the demand for the manufacturers and tell the real-time sales from the cash registers (Lu, 2018).

- They have invented radio frequency tags, which helped them to reduce the 16% out-of-stocks. These tags are readable in various places like docks, shelves, warehouses, and recycled areas (Lu, 2018).

These are some of the capabilities that help Wal-Mart to attain a competitive advantage through the supply chain.

2. How is Wal-Mart doing? How does it compare to its competitors?

Wal-Mart is the leading grocery retailer worldwide. Every year, the company is increasing its total revenue by 5.65 % compared with its competitors. However, this year, its profitability is less than its competitors by a net margin of 4.67%.

Wal-Mart’s net income has increased by 74.97%, faster than the development of its competitors, which is 51.92% (CSI Market, 2020). This shows that with the increased income, their operating costs are also rising, due to which their net profit is not that much growing.

Simultaneously, the statistics show that the profit margin has been consistent for many years, resulting in cost reduction and management.

The main reasons behind Wal-Mart’s retail business’s success are increasing online and in-store sales, comprehensive financial services, a large number of pet product buyers, a pricing strategy, a large scale of operations, and bargaining power.

These are the main factors responsible for Wal-Mart’s success instead of supply chain management. One more aspect is that there is no labor union or any union; therefore, the system and processes would never be affected due to external distractions (Pratap, 2018).

Some years before 2017, Wal-Mart faced…

Unlock Case Solution Now!

Get instant access to this case solution with a simple, one-time payment ($24.90).

After purchase:

- You'll be redirected to the full case solution.

- You will receive an access link to the solution via email.

Best decision to get my homework done faster! Michael MBA student, Boston

How do I get access?

Upon purchase, you are forwarded to the full solution and also receive access via email.

Is it safe to pay?

Yes! We use Paypal and Stripe as our secure payment providers of choice.

What is Casehero?

We are the marketplace for case solutions - created by students, for students.

Wal-Mart’s Supply Chain Management Practices

January 8, 2010

Case Study Abstract

The focus of this case study is the supply chain of the world’s largest retailer, Wal-Mart. Wal-Mart in recent years has struggled with its supply chain. The big question is: Will Wal-Mart be able to revive the competitive advantage it had in the past with its efficient supply chain? This case discusses the supply chain management practices of Wal-Mart over the years. A brief of Wal-Mart’s past distribution, logistics and inventory management processes is covered. The use of innovative Information Technology (IT) practices to enable the supply chain is discussed and highlighted. The benefits or competitive advantage Wal-Mart derived over the years from its supply chain management practices is also covered.

Table of Contents

- Introduction – Can Wal-Mart sustain its Supply Chain Advantage?

- Wal-Mart in US Retail Market

- Wal-Mart – Company Background

- Wal-Mart – Timeline

- Wal-Mart: Quick Facts (Revenues, Total Employees and Stores, Competitors, Major Brands/Labels, Business/Growth Strategy)

- MANAGING THE SUPPLY CHAIN – THE WAL-MART WAY

- Pricing and Procurement Strategy

- Supply Chain Integration through Product/Process Knowledge Sharing

- Supply Chain Partnerships

- Distribution Strategy

- Logistics Management

- Cross Docking

- Inventory Management

- Store Formats

- Wal-Mart – International operating formats

- Related Reading

- Questions for discussion

- View sample pages of this case study

Case Study Keywords: Wal-Mart, Supply Chain Management, Retailing Strategy Case Study, Logistics and Distribution, IT enabled supply chain, Information Technology, Supply Chain Partnerships, supply chain integration, information sharing, inventory management, retail store formats, cross docking, pricing and procurement, Sam Walton, discount stores, walmart.com.

Case questions for discussion.

- Wal-Mart’s focus on supply chain management is responsible for its leadership in the retail industry. Discuss the distribution and logistics practices adopted by Wal-Mart. How far has Wal-Mart’s supply chain contributed to its competitive advantage? Explain.

- Companies that have significant buyer power and are very focused on exerting price pressure on their suppliers rather than seeking increased profitability through business process innovations. Support this statement with examples/best practices from your own field.

- Wal-Mart has always used innovative information technology tools to supplement its supply chain. In a few words, explain how use of IT tools/enabled processes have benefited Wal-Mart. How has IT impacted you/your department?

- What steps can Wal-Mart take in order to revive/sustain its supply chain advantage?

- Wal-Mart invited its major suppliers to develop profitable supply chain partnerships. Discuss how good/bad is sharing knowledge/critical information with vendors/suppliers or even customers?

- “It’s not a sale; it’s a great price you can count on every day to make your dollar go further at Wal-Mart.”, as quoted in the article, “Pricing Philosophy,” posted on www.walmart.com. Comment.

Other Case Studies on Wal-Mart

- Organization Culture at Wal-Mart

- Wal-Mart in Japan

- Tesco takes on US Wal-Mart

Case Updates/Snippets

- Wal-Mart’s new slogan – In September 2007, Wal-mart changed its slogan to “Save Money. Live Better.” Wal-Mart’s earlier slogan for 19 years was “Always Low Prices.”

- Benefits of shopping at Wal-Mart – According to a study by research firm Global Insight, Wal-Mart saves American families $2,500 each year. This figure rose from $2,329 in 2004 by 7.3 percent.

- Wal-Mart’s new slogan in 2011 : Wal-Mart’s latest tagline is “Low Prices. Every Day. On Everything.”

- Wal-Mart Online – Wal-Mart has 10,000 stores globally with annual revenues of more than $400 billion and 200 million weekly shoppers. According to Internet Retailer, it ranks six as in the largest Internet retailer list. Wal-Mart trails Amazon.com Inc, Staples Inc, Apple Inc, Dell Inc and Office Depot Inc. Wal-Mart does online business in United States, the UK, Canada and Brazil and does not reveal the percentage of online sales. Its digital technology unit called @WalmartLabs targets smartphones and social networking audience.

Walmart Supply Chain: What Makes It (Still) So Successful

By Meredith Flora Last updated on February 23, 2024

Need Help With Order Fulfillment? ShipBob Can Help.

Subscribe for more.

Enjoying this article? Join the tens of thousands who get the latest from ShipBob’s blog emailed every other week.

Table of Contents

What makes Walmart’s supply chain so successful?

Walmart and shipbob’s winning fulfillment combo, walmart supply chain faqs.

With a revenue of over $570 billion , Walmart continues to rank number one on Fortune’s Global 500 list. This marks their ninth consecutive year at the top position, making Walmart the largest company in the world by revenue.

Walmart’s success can be attributed to having their own supply chain to streamline fulfillment and cut down on costs. It also provides them with more control over their logistics network .

In this article, we take a closer look at the Walmart supply chain and why it continues to be so successful decades later.

Walmart’s supply chain success can be attributed to their tactful decisions to start investing in the right initiatives, including technology and expanding their logistics network, to provide value in the ecommerce space.

Below we break down the various initiatives that has made Walmart’s supply chain successful.

Early investment in supply chain optimization

Walmart’s focus on optimization is one of the largest factors contributing to the brand’s supply chain success.

The retail giant is constantly striving to improve existing systems and processes to create an optimized and efficient supply chain to provide their customers with “everyday low prices” — one of the company’s unique (and renowned) selling points.

Among the many supply chain optimization strategies, the company places great emphasis on omnichannel — multiple channels available to its customers. Walmart’s Marketplace creates a home for thousands of retail stores with the ultimate goal to save time for the consumer.

Walmart also provides multiple marketplace fulfillment options, such as in-store pickup, ship from store, and even digital pharmacy fulfillment. Globally, Walmart offers 7,000+ pickup locations and 5,000+ delivery locations.

Fine-tuning the supply chain management system

Walmart is constantly striving to improve their supply chain management system.

From the get-go, the company started removing links within the supply chain and purchased goods in bulk to be transported directly to their stores.

They then began working directly with manufacturers and distributors to cut out the middleman to further streamline the supply chain.

This approach plays a key role in their supply chain success. With fewer players in the supply chain, the company can lower costs and cut back on lead times to offer quick and affordable fulfillment .

Developing strong relationships with vendors early on

Walmart’s strong relationships with vendors have played a major role in their supply chain success. They go straight to the source and identify vendors who can provide them with the best price and can meet their high-volume demands.

Walmart establishes strategic partnerships with these vendors, guaranteeing them consistent business through long-term, high-volume purchases. In return, the company can enjoy wholesale prices, which keeps customer prices competitive throughout the years.

To further strengthen these relationships, Walmart also establishes open communication networks with their vendors. This allows them to improve the flow of inventory within the supply chain and anticipate possible disruptions before they escalate into larger problems, such as backorders , stockouts, and delivery delays.

Outsourcing inventory control with vendor managed inventory (VMI)

Walmart has further strengthened and simplified their supply chain by implementing a vendor management inventory (VMI) model.

VMI involves suppliers managing their own inventory that’s stored in Walmart’s warehouses. With this approach, the company puts the responsibility of managing inventory in the hands of suppliers, so they can save time and money on inventory management.

With an electronically backed VMI system, suppliers have access to Walmart’s inventory data, allowing them to keep track of real-time inventory levels and sales. This makes it easy monitor how much stock is available and how certain products are sold.

Based on this information, they can see when they need to send more inventory to Walmart and keep their stock replenished.

This simplified inventory management model results in fewer delays in replenishment and reduces stockouts. It’s particularly useful since Walmart deals with hundreds of thousands of SKUs from thousands of suppliers, which can get complicated and expensive to manage.

By transferring some of the inventory control activities to the vendors, the company can save time and focus on tasks that need to be handled in-house.

It also means that Walmart doesn’t need to spend more on dedicated personnel to manage the inventory coming from each supplier, which results in lower costs for them. All Walmart has to do is monitor the transport of inventory from warehouses to their stores.

Capitalizing on the power of technology

As Walmart undergoes a digital transformation , they’re making extensive investments in supply chain digitization and infrastructure. These investments have contributed to the successful supply chain that we see today.

Between 2019 and 2020, 72% of Walmart’s strategic capital expenditures were attributed to supply chain transformation , which includes supply chain technologies, infrastructure, and ecommerce. During this period, the company spent more than $11 billion.

These investments have resulted in faster, more flexible fulfillment , and more accurate demand forecasting .

Walmart also uses technology in their initiative to reduce packaging waste. Packaging algorithms make it easier to find the right-size packaging for each product by accurately capturing product dimensions and other attributes.

Additionally, Walmart has implemented an advanced warehouse management system (WMS) in their distribution centers . This more nuanced WMS supports better inventory control and labor planning to streamline their supply chain operations .

Overall, one of the largest technological investments they’ve made is in automation. Autonomous mobile robots are helping warehouse staff move pallets, while other automation tools are used for picking items or packing them inside containers.

Walmart has also made significant investments in sortation equipment, which will automatically sort products and allocate them to the right locations within the warehouse. Robust warehouse control systems help to establish a link between these automation equipment and the WMS.

ShipBob is an official Walmart partner and participates in Walmart’s TwoDay delivery program .

ShipBob’s fulfillment platform integrates with Walmart Marketplace to display free 2-day delivery badging and fulfills 2-day orders approved by marketplace sellers.

Here is how ShipBob’s integration with Walmart works.

Two-day shipping

By connecting ShipBob with Walmart , businesses can provide two-day shipping with 100% coverage across the continental United States.

You can connect your Walmart store to ShipBob in minutes, sync your inventory, and choose what fulfillment center locations to send inventory to.

Your “Free 2-day delivery” badge will appear prominently near the “Add to Cart” button, which captures attention and generates, on average, 50% more conversions.

ShipBob’s on-time delivery rate is over 95%, which provides merchants with reliability and speed.

“DTC is our bread and butter, and with ShipBob we can offer 2-day shipping, gift notes, and other aspects of the modern delivery experience that consumers want.” Aaron Patterson, COO of The Adventure Challenge

Warehousing

ShipBob offers warehousing solutions to help you manage your inventory more efficiently. When you outsource fulfillment to ShipBob, our team of fulfillment experts take care of the entire process of receiving, storing, and managing your inventory.

By storing your inventory across one or more fulfillment center location, you benefit from lower warehousing costs while also improving delivery speeds.

Once ShipBob receives your inventory and orders are placed on Walmart.com, they are automatically sent to ShipBob to be picked, packed, and shipped.

From the ShipBob fulfillment platform, you can track activity, manage SKUs and inventory levels across locations, and view storage costs.

“ShipBob’s analytics are a huge bonus for a merchant looking to partner with a single 3PL that has a built-in order management tool. I was so stoked about being able to see the optimized layout of where you should be distributing your inventory is great. Having inventory and warehouse management capabilities built into your 3PL is such a value-add, especially for smaller companies.” Juliana Brasil, Director of Operations at Food Huggers

Inventory management

ShipBob’s inventory management tools further simplify the fulfillment process by providing a single dashboard to view real-time inventory levels across locations.

With real-time insight into inventory, you can get ahead of inventory replenishment, access data to improve demand forecasting, and make better business decisions.

You can even keep track of the number of units sold per day, so you know when to prepare for inventory replenishment. From the ShipBob dashboard, you can use the inventory data available to set reorder points to prevent stockouts .

Walmart integration

ShipBob’s integration with Walmart improves product visibility on Walmart Marketplace while also having your orders fulfilled through ShipBob.

Thanks to ShipBob’s omnichannel fulfillment capabilities, your inventory levels are updated in real time to reflect the purchases across all your sales channels, including Walmart. This way, you don’t end up accidentally selling more products than you have in stock.

With the Walmart integration, you can get your products in front of millions of customers and provide a seamless order fulfillment experience.

To learn more about how ShipBob partners with Walmart, contact ShipBob today.

Here are answers to the top questions about Walmart supply chain.

Does Walmart have its own supply chain?

Yes, Walmart has one of the largest supply chains in the world. Their nuanced supply chain establishes a more direct relationship between vendors and end consumers. Walmart runs their own distribution centers and partners with logistics companies like ShipBob to further expand their supply chain network.

What is Walmart’s supply chain strategy?

Walmart’s supply chain strategy is highly focused on direct, long-term relationships with manufacturers, distributors, and ecommerce businesses. The goal is to reduce the number of touchpoints within the supply chain to reduce lead times and speed up fulfillment. Walmart also heavily invests in supply chain technology to improve efficiency and accuracy throughout their network.

What are the advantages of selling on Walmart Marketplace?

Selling on the Walmart Marketplace will give you access to the retailer’s 120+ million monthly customers. This means you can get your products in front of a massive audience, which will improve the chances of boosting sales. Moreover, the Walmart Marketplace doesn’t charge you any monthly fees. Marketplace fees are commission-based, which means you only pay a fee when you make a sale.

Written By:

Meredith Flora

Meredith is a Content Marketing Specialist at ShipBob, where she writes articles, eGuides, and other resources to help growing ecommerce businesses master their logistics and fulfillment.

Read all posts written by Meredith Flora

Subscribe to our blog

Join tens of thousands of ecommerce brands to get more articles like this and our latest resources delivered to your inbox.

Just for you

Latest tips to improve ecommerce logistics.

How to Measure and Improve Your Supply Chain Metrics

Reverse Logistics Meaning and Process Explained

How iVYVERDURE Got Time Back For Growth by Outsourcing to ShipBob [Case Study]

Shipbob offers outsourced fulfillment and a wms if you have your own warehouse. request a quote by filling out the form..

A fulfillment expert will get back to you shortly.

Loading Job...

Job description:.

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

How Walmart Automated Supplier Negotiations

- Remko Van Hoek,

- Michael DeWitt,

- Mary Lacity,

- Travis Johnson

Using a chatbot allows the procurement team to focus more on strategic relationships, exceptions, and continuous improvement.

It’s an age-old problem in procurement: Corporate buyers lack the time to negotiate fully with all suppliers. Historically this has left untapped value on the table for both buyers and suppliers. To address this challenge, Walmart deployed AI-powered negotiations software with a text-based interface (i.e., a chatbot) to connect with suppliers. So far, the chatbot is negotiating and closing agreements with 68% of suppliers approached, with each side gaining something it values. This article offers four lessons to deliver results from automated procurement negotiations: move quickly to a production pilot, start with indirect spend categories with pre-approved suppliers, decide on acceptable negotiation trade-offs, and scale by extending geographies, categories, and use cases.

Walmart, like most organizations with large procurement operations, can’t possibly conduct focused negotiations with all of its 100,000-plus suppliers. As a result, around 20% of its suppliers have signed agreements with cookie-cutter terms that are often not negotiated. It’s not the optimal way to engage with these “tail-end suppliers.” But the cost of hiring more human buyers to negotiate with them would exceed any additional value.

- Remko Van Hoek is a professor of supply chain management at the University of Arkansas’s Sam M. Walton College of Business. He previously served as a chief procurement officer at a number of companies.

- Michael DeWitt is vice president of strategic sourcing at Walmart International.

- Mary Lacity is the David D. Glass Chair and Distinguished Professor of Information Systems at the University of Arkansas’s Sam M. Walton College of Business.

- Travis Johnson is senior director of procurement enablement solutions at Walmart International.

Partner Center

MBA Knowledge Base

Business • Management • Technology

Home » Management Case Studies » Case Study: Supply Chain Management of Walmart

Case Study: Supply Chain Management of Walmart

The world’s largest retailer Wal-Mart was founded by Sam Walton in the year 1962. He opened his first store in Rogers, Ark. On 31st October 1969, the company was incorporated as Wal-Mart Stores. Key success factor was the guidance of Sam. Presently they are operating in fifteen countries with more than 8,000 stores with 2.1 million employees (2009). Major features of Wal-Mart stores are its store area, cleanliness and its shelves which is filled with varieties of quality items that includes health care products, family apparels, electronic items, automotive products, hardware items, jewelry etc.

Wal-Mart is giving more emphasis for customer needs and tried to reduce cost through the effective usage of supply chain management system . In the year 2009, Fortune Magazine ranked Wal-Mart as first among other retailers in its survey. Sales were about 401 billion U.S dollars in the FY 2009. Sam Walton claims that Wal-Mart’s vision had always been to increase sales through lowering the costs through organized distribution system with the help of the Information Technology. It is said that Wal-Mart’s extreme success could be attributed to its effective supply chain management.

Wal-Mart’s efficiency in supply chain management was due to two key factors namely automated distribution center and the computerized inventory system. This brought in minimizing a lot of time the later not only reduced the checking out time but also recorded the transaction which is much needed to know envisage demand. Demand forecast is a constant issue which could be a threat when not handled properly. This is due to the fact that demand prediction is always inaccurate. Aggregation would be a remedy for this unpredictable demand.

Wal-Mart’s focus has always been to sell goods at a lower price to the customers. They ensured direct purchase form the companies bypassing the intermediaries. This by passing is one of the ways to reduce cost. Wal-Mart preferred small vendors to the big players however the vendor who provides the best price qualifies and gets the deal. This applies to the giants like P& G as well. Their practice these days had been choosing few vendors and they literally negotiate the best price the one that comes up with the best price qualifies. This does not blindly mean that they have been ruthless. Wal-Mart also work with the vendors for improving its supply chain efficiency.

Wal-Mart with its power distribution system made quite innovative changes like reducing paper work, reduced its lead time drastically, used bar codes to bill which recorded inventory levels and the access to the stock levels served as the valuable data for management. The movements of products are systematic and strategically aliened in a way that it reduces the most valuable time and cost and results in efficiency. Wal-Mart had a very effective rather responsive and flexible distribution system to transport goods from docks to stores. It educated the drives with the ethics and code of conduct which pictures their supply chain responsibility. Cross docking is one lethal weapon that was used by Wal-Mart in their SCM.

Cross Docking: Cross Docking is a method of handling goods. This happens when vendor and the company work together. This is the method of supplying the product in the right time and the said quantity. This cut down a lot of time. This also changed Wal-Mart’s way of looking things. This transitioned Wal-Mart from being a centralized management to almost decentralized system took a major turn in focus of pull strategy than a pull strategy.

Cross-docking is one of the techniques used by Wal-Mart. It means there is no unnecessary storage or little storage in between the loading and unloading of goods so that customer can enjoy the quality of the goods by first hand. Wal-Mart have logistics infrastructure which is very fast transportation system wherein the distribution centers are being serviced. Wal-Mart assured that their drivers are capable of doing their jobs accordingly and do not cause unnecessary delays that can hamper the efficiency of the distribution operations. To deliver it on time, the coordinators give information to the driver the expected time of arrival or delivery of the goods.

Point Of Sale: Information sharing is one of the most important things when it comes to SCM. P&G with its Pampers requested Wal-Mart to share its point of sale so that it could predict its demand more or less and work on the information to bring in efficiency. When Wal-Mart shared this information P&G could plan in advance and it with its efficient supply chain management could supply pampers to Wal-Mart on time.

Wal-Mart did not want to dedicate lot of space to pamper in its warehouse of shop store either. Instead the supply was taken care by P& G. This led the initiation of working with the vendors and coming out with huge efficiency by maintaining lower inventory and satisfying demand without stock outs. Thus point of sale sharing would be a key element for any company for its further scope of improvement and also when there is further scope of improvement there is a role for Supply chain management.

Related Posts:

- Case Study of McDonalds: Advertising and Promotion Strategies

- Case Study of Dell: Primary Target Markets and Positioning Strategy

- Case Study: Zara's Supply Chain Success Story

- Case Study: How Walmart Enhances Supply Chain Management with ERP Initiatives?

- Case Study of Zara: Use of Technology to Improve Operational Responsiveness

- Case Study: Why Walmart Failed in Germany?

- Case Study of Johnson & Johnson: Using a Credo for Business Guidance

- Zara's Lean Operation: Source of Competitive Advantage

- Case Study: The International Growth of Zara

- Case Study of Zara: A Better Fashion Business Model

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

A Case Study of Wal-Mart's "Green" Supply Chain Management

Related Papers

Paper to be presented at conference on Global …

Barry Eidlin

Canadian Journal of Economics/Revue canadienne d'économique

Amanda Pyman

Patrick Hayden

Neeraj Anand

Supply Chain Management has emerged as one of the major key area for companies to gain competitive advantage in the market. It has been identified to have a significant impact on the natural environment and has resulted in a growing need for integrating environmental thinking into supply chain management and its processes, hence the companies are getting more attention as a sustainable development mode for modern enterprises, increasingly a part of Corporate Social Responsibility (CSR) initiatives and investing to achieve greener supply chain which can be waste eliminating, productivity improving and resource saving. This paper study the Green supply chain practices and green initiatives by an American multinational retailer Wal-Mart (World's largest public corporation & retailer in the world), who has strengthened their supply chain management and coordination across the supply chain elements such as strategic sourcing, logistics management, supply chain information systems, an...

Walmart Policy and Sustainability Challenges

Oketch Michael

Global companies' primary goals are global expansion, sustainability, and considerable market. Sam Walton founded the US retail giant Walmart in 1962. It manages widespread networks of discounted retail warehouses and stores (Williams, 2019). In 2022, Walmart took first in Forbes's Top 500 Fortune companies in market capitalization (Struckell et al., 2022). It is in several nations, including the USA, Argentina, Canada, and Brazil (Williams, 2019). For an extended period, Walmart has endured criticism for its dismal employee treatment, which has been the primary reason for global complaints. This international attention has hindered its global expansion, such as the failure t penetrate the German market. Several factors, including the company's supposedly poor pricing policies and low wages, have contributed to Walmart's rising negative brand image. Despite the company's critics, economists maintain that Walmart has a net beneficial impact on the global economy because it is the largest employer worldwide, with about 2.2 million employees (Alshahari, 2021). The company should re-evaluate its policy to curb growing competition and consumer-changing behavior. Policy and operational adjustment provide a solution to Walmart achieving its sustainability goals and retaining its market share.

Marisa Avila

Seyad Subuhan

Rudresh Pandey

Walmart was established by Sam Walton and beginning as a small discount retailer in Rogers, Arkansas in 1962. This paper investigates how Walmart become popular and successful in retail business around the world and how they perform well in sales. This study found that some factors were leading to the success of Walmart. Since then, Walmart has become the most trusted retailer that creates value for business and society.

Murray Rice

This research aims to provide insight regarding Wal-Mart’s retail development strategy in its expansion across the continental United States. The study examines store location patterns and relationships between Wal-Mart’s store and distribution center locations and markets. The study shows that, although radial expansion is broadly characteristic of the dense store patterns that have been well established for Wal-Mart at the national level, expansion patterns at the regional level are consistent with a selective process based on factors other than store density. These results provide a new perspective on Wal-Mart’s expansion, providing insights of value to retail practitioners and local government. Key Words: distribution center location, location intelligence, retail chain expansion, store location, Wal-Mart.

Annual Review of Sociology

Michelle Christian

Wal-Mart has been both praised and pilloried as a template for twenty-first century capitalism. Therein lies the challenge in analyzing the world's largest retailer. We examine the sociological impact of Wal-Mart in terms of four themes: its business model and organizational structure, the dual impact of Wal-Mart's labor relations in terms of its own stores and working conditions in its

RELATED PAPERS

Dokter Ryan

Report of the Secretary General 2012 Stigmatization of Minorities of Religion or Belief within the School System

Valle thierry

Namjoon Cho

JasaCetak AmplopCepat

Archivos Venezolanos de Farmacologia y Terapeutica

Holger Ortiz

IEEE Transactions on Medical Imaging

Teoria del diritto e dello Stato 1-2

Giuseppe Foglio

Enrica Donisi

Alma Rosa Islas Rubio

Oxidative medicine and cellular longevity

Dharamvir Arya

Egyptian Journal of Dermatology and Andrology

Ayman Elkholy

SPIE Proceedings

Danping Peng

Clinical Infectious Diseases

Rima Moghnieh

Biochimica et Biophysica Acta (BBA) - Bioenergetics

Eugenia Trushina

Phytopathologia Mediterranea

Vittorio Rossi

XIIIèmes JNGCGC Dunkerque

koffi kra emmanuel Koffi

The Journal of Organic Chemistry

Thomas Cailly

EKOBIS SYARIAH

Winny Dian Safitri

Philippe Leduc

Journal of Operational Oceanography

Rodrigo Bustamante

Proceedings of the 2010 ACM SIGPLAN workshop on Partial evaluation and program manipulation

Juan Rodríguez Hortalá

Mini-invasive Surgery

Fabio Magliocca

emily grace

Astronomy & Astrophysics

Dominik Utz

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Order Status

- Testimonials

- What Makes Us Different

Walmart Supply Chain Harvard Case Solution & Analysis

Home >> Harvard Case Study Analysis Solutions >> Walmart Supply Chain

Introduction

The report illustrates the view of the business from a consultancypoint of view. Itentails the functioning of Walmart in the markets from its imitation.Since from the initiation, underthe leadership of Sam, the company adopted the cost-leadership strategy and offered the model of “everyday low prices” in US and Canada. Such model gained immense popularity and thus raised the brandawareness which ultimatelyled to building strongbrandimage in the market.

Walmart from its inceptionfocused on its supply chain efficiency to gain competitive edge in the market. It developed the models such as stock keeping units and cross dockings to reduce inventory costand toincrease the effectiveness of business in targeted markets. Such adoption of model allowed it to penetrate markets efficiently, depending on the fundamental factor of cost leadership.

In addition, the company also incorporated technology such as point of saletechnique to managethe inventory and to locate the shelfspaceaccordingly with right running product.Although, the company has gained enough brand loyaltyandbrand equity in the market, three problems are threatening the business sustainability of Walmart.Such issues include (Emergence of new business models-convenience stores (2) Ecommerce Giants-Amazon and (3) Imitation of the supply chains strategy of Walmart by other business.

The report is hence designed to highlight those issues and outline the roles of in bringing theright outcomes for company through right and adequate number of deliverables.

Keywords : Competitive Edge, Supply chain

Walmart Supply Chain Harvard Case Solution & Analysis

Walmart is one of the world’s largest brick and plasterretailer. Its revenue increased to $67 billion in 1993 from $16 billion in 1987. The founder of the company was Sam Walton who first opened a retail shop by the name of Ben Franklin franchise store in 1945. Around the year 1994, Walmart had around 1,953 overall stores in U.S. One of the key strategies for the Walmart distribution is it would establish its retail stores in low population rural areas where its competitor would ignore building stores.

Over the period of time, the company increased in size and pursued the market penetration strategy to capture big market share in US. Till now Walmart has 11695 stores and clubs in more than 28 countries. The company has the world’s largest revenues of $480 billion with employee base of 2.3 million. The company has substantial market share and sales revenues from the US market and accounts.

Since from the initiation of the Walmart business, the company focused on its supply chain functions to manage its cost of operations and to offer price cutting strategy products in the market. In doing so, the company focused on backward integration and forward integration as well so to have a strong control over the operation and organizational function.

Walmart in initiating its smart and well-integrated business operations opened up its own distribution centers and applied the smart supply chain management techniques such as POS and SASS management to manage the inventory.Such techniques and expertise allowed WALMART to manage the inventory cost and cost stacked up into the inventory. (Sehgal, 2014)

It has been Walmart that initiated the stock keeping..............

This is just a sample partical work. Please place the order on the website to get your own originally done case solution.

Related Case Solutions & Analyses:

Hire us for Originally Written Case Solution/ Analysis

Like us and get updates:.

Harvard Case Solutions

Search Case Solutions

- Accounting Case Solutions

- Auditing Case Studies

- Business Case Studies

- Economics Case Solutions

- Finance Case Studies Analysis

- Harvard Case Study Analysis Solutions

- Human Resource Cases

- Ivey Case Solutions

- Management Case Studies

- Marketing HBS Case Solutions

- Operations Management Case Studies

- Supply Chain Management Cases

- Taxation Case Studies

More From Harvard Case Study Analysis Solutions

- DigitalThink: Building a Sales Force

- The Power of Reconnection -How Dormant Ties Can Surprise You

- DW Healthcare Partners

- Robert Little and the Kinship Fostercare Program in NYC (Epilogue)

- Former Cape broker named in stock scam

- Cleveland Clinic: Transformation and Growth 2015

- The Puerto Rico Pill Trials

Contact us:

Check Order Status

How Does it Work?

Why TheCaseSolutions.com?

Tracking food for better safety

We rarely think about it, but the modern food system is a marvel. We have access to fresh produce all year round, buy exotic food from all around the world, and have more variety than our ancestors could ever dream of.

Our food is generally safe to eat. Still, occasionally it can make us sick. Last year in 2018 there were at least 18 reported outbreaks of foodborne illnesses in the USA, including the E. coli found in romaine lettuce.

“People talk about the food supply chain,” says Frank Yiannas, former Vice President of Food Safety at Walmart. “But it is not actually a chain, it’s a complex network.” When an outbreak of a food-borne disease does happen, it can take days, if not weeks, to find its source. If investigators cannot point to a specific farm or farms, the government usually advises consumers to avoid products grown in a certain area (as happened with romaine lettuce from Yuma, Arizona), or even to avoid the type of product altogether. According to Walmart , millions of bags or heads of lettuce had to be removed, and consumers lost confidence in romaine lettuce altogether. Better traceability could help save lives by allowing companies to act faster and protect the livelihoods of farmers by only discarding produce from the affected farms.

For this reason, Walmart has always been interested in enhancing transparency and traceability in the food system. Mr. Yiannas explains that the company has tried many systems and approaches to solving this problem over the years; none had brought them the kind of results they were after. When Yiannas first heard about blockchain and the idea of using it to trace food in the supply chain, he was skeptical.

From blockchain skeptic to believer

Karl Bedwell, Senior Director at Walmart Technology, explains, “Creating a (traceability) system for the entire food supply ecosystem has been a challenge for years, and no one had figured it out. We thought that blockchain technology might be a good fit for this problem, because of its focus on trust, immutability, and transparency.”

Bedwell and his team introduced Yiannas to the possibilities of blockchain technologies for enterprise solutions. Says Yiannas, “I really had an “aha” moment once I deeply understood the technology. I had been hesitant about creating yet another traceability system – the ones we had tried in the past never scaled. Now I understand that was because they were centralized databases. Blockchain, with its decentralized, shared ledger felt like it was made for the food system!”

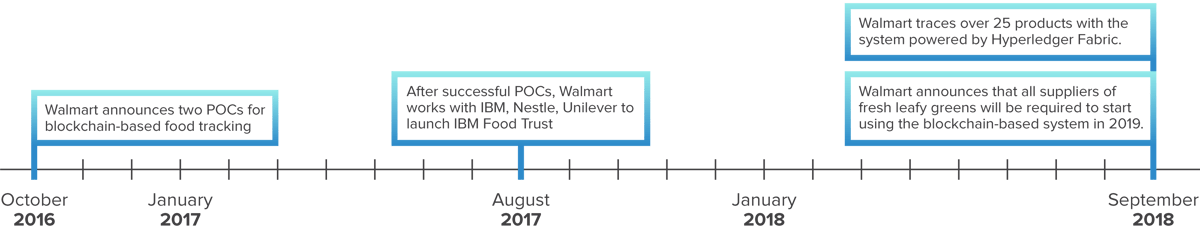

With the business interest in blockchain technology confirmed, Walmart started working on two proof of concept (POC) projects with their technology partner IBM.

Choosing the blockchain

Walmart Technology considered several blockchain technologies but ultimately decided to go for Hyperledger Fabric.

“IBM brought Hyperledger Fabric to us. We looked into Ethereum, Burrow project and others. Ultimately, we decided to go with Hyperledger Fabric because it met most of our needs for a blockchain technology,” Bedwell said. “We felt that it best met our needs. It is an enterprise-grade blockchain technology, and it is permissioned.”

The team also found it important to work with an open-source, vendor-neutral blockchain. Since the food traceability system was meant to be used by many parties, including Walmart’s suppliers and even direct competitors, the technology ecosystem underlying it needed to be open.

Hyperledger Fabric is a blockchain framework implementation and one of the Hyperledger projects hosted by The Linux Foundation. Intended as a foundation for developing applications or solutions with a modular architecture, Hyperledger Fabric allows components, such as consensus and membership services, to be plug-and-play. Hyperledger Fabric leverages container technology to host smart contracts called “chaincode” that comprise the application logic of the system.

For mangoes in the US, the time needed to trace their provenance went from 7 days to… 2.2 seconds!

In October 2016, Walmart, together with its technology partner IBM, announced the two projects: one was about tracing the origin of mangos sold in Walmart’s US stores and the other aimed to trace pork sold in its China stores.

For the mango POC, Yiannas started by creating a benchmark. He bought a packet of sliced mangoes at a nearby Walmart store and asked his team to identify which farm they had come from – as fast as possible. The team started calling and emailing distributors and suppliers, and eventually had an answer almost seven days later. This was not bad by industry standards, but Walmart wanted to do much better. So together with IBM, they got to work building a blockchain-based food traceability system.

The Walmart Technology team looked at their own processes as well as those of their suppliers to design the application. Archana Sristy, Director of Engineering at Walmart, explains, “[Our team at Walmart Technology] co-led the core design and setup of the application (with IBM), as well as built the integration with the enterprise systems. We worked with GS1 (the standards authority in barcodes and labeling) to define the data attributes for upload to the blockchain. IBM wrote the chaincode.

Suppliers used new labels and uploaded their data through a web-based interface.

From POC to production, from Walmart to IBM Food Trust

Once Walmart saw that the system worked, they wanted to expand it – and not just within Walmart. Given the interconnected nature of the food system and the company’s negative experience with closed systems, Walmart wanted to make sure that this time, many players were involved. Says Yiannas, “(Walmart’s) CEO was reaching out to other food companies the next day, including other retailers!” Wal-Mart collaborated with IBM and others to set up IBM Food Trust , involving prominent players in the food industry, like Nestle and Unilever.

The Walmart team had a positive experience working with Hyperledger. “Every question that we had, it looked like the Hyperledger community had already been working on addressing that,” says Bedwell. For example, in building a truly open system, the Walmart team worried about interoperability with other blockchain-based traceability systems. And as if in answer to their concern, Hyperledger recently announced its collaboration with Ethereum. He adds, “It seems that the Hyperledger community is addressing everything that enterprises would be concerned about.”

Says Yiannas, “I really had an ‘aha’ moment once I deeply understood the technology. I had been hesitant about creating yet another traceability system – the ones we had tried in the past never scaled. Now I understand that was because they were centralized databases. Blockchain, with its decentralized, shared ledger felt like it was made for the food system!”

Tips from Frank Yiannas on implementing your blockchain project

1. Let the business lead the project , not the IT department.

2. Understand the business case deeply. Make sure that you know and can explain why blockchain is the right solution.

3. In a large organization, you need to bring a lot of people along. Think about all the different departments that will be affected by the projects. Meet with these stakeholders early on and explain what you are trying to do.

4. Have your soundbite! People don’t get inspired by technology, but by a vision. For us, it was the story of mangoes – 7 days vs. 2.2 seconds with blockchain.

5. Participate in forums that allow you to speak to other companies who have launched similar projects successfully. It helps if you help an expert in the field who’s willing to come in and educate fellow members.

6. Start small, with a POC. And when you’ve run your pilots and are convinced about the business value, go ahead and scale. After all, Yiannas says, “Walmart is a pretty big lab! If it can scale at Walmart, it can scale anywhere!”

Looking forward

Walmart now traces over 25 products from 5 different suppliers using IBM Blockchain which is built atop Hyperledger Fabric. The products include produce such as mangoes, strawberries and leafy greens; meat and poultry such as chicken and pork; dairy such as yogurt and almond milk; and even multi-ingredient products such as packaged salads and baby foods.

Yiannas says of the impact, “This solution allows us to see the whole chain in seconds! We can take a jar of baby food and see where it was manufactured and trace back all the ingredients to the farms!”

Walmart plans to roll out the system to more products and categories in the near future in cooperation with IBM Food Trust.. In fact, the company recently announced that it will start requiring all of its suppliers of fresh leafy greens (like salad and spinach) to trace their products using the system.

“Using the IBM Food Trust network that relies on blockchain technology, we have shown that we can reduce the amount of time it takes to track a food item from a Walmart Store back to source in seconds, as compared to days or sometimes weeks,” Walmart wrote in a letter to suppliers.

Beyond tracing the products’ journey, the company might start tracing other data, like sustainability.

About Walmart

Walmart Inc. (NYSE: WMT) helps people around the world save money and live better – anytime and anywhere – in retail stores, online, and through their mobile devices. Each week, nearly 265 million customers and members visit our more than 11,200 stores under 55 banners in 27 countries and eCommerce websites. With fiscal year 2018 revenue of $500.3 billion, Walmart employs over 2.2 million associates worldwide. Walmart continues to be a leader in sustainability, corporate philanthropy and employment opportunity. Additional information about Walmart can be found by visiting http://corporate.walmart.com .

About Hyperledger

Hyperledger is an open source collaborative effort created to advance cross-industry blockchain technologies. It is a global collaboration including leaders in banking, finance, Internet of Things, manufacturing, supply chain, and technology. The Linux Foundation hosts Hyperledger under the foundation. To learn more, visit hyperledger.org

Sign up for Hyperledger Horizon & /dev/weekly newsletters

By signing up, you acknowledge that your information is subject to The Linux Foundation's Privacy Policy

Building Insights Into Supply Chains: A Case Study

Image: iStock.com/metamorworks

For time-sensitive or temperature-controlled cargo, most shippers will agree that high-quality, real-time tracking information is crucial. Though that technology can be expensive, the investment is easy to justify when it could mean the difference between an on-time delivery and spoiled cargo. But for general cargo — which does not have strict timeline requirements — it can be harder for shippers to justify that cost. Individualized tracking information simply isn’t as critical for those standard loads. And if shippers do decide to invest in tracking devices for general cargo, rarely is the technology advanced enough to make a sizable difference to their bottom line.

Some leaders in the shipping space argue that this view is shortsighted — and could cost companies far more than they realize. Without the data that tracking technology could provide, they believe, many shippers lose out on important insights into their general cargo — data that could significantly improve travel timelines and ultimately justify that initial cost.

Two of these leaders are Maersk, a provider of transportation and logistics services, and Tive, a global leader in supply chain and logistics visibility technology. Both organizations felt that the potential value of tracking insights into general cargo was too important to overlook. So when Erez Agmoni, global head of innovation at Maersk, and Krenar Komoni, founder and CEO of Tive, crossed paths at a supply chain event at MIT a few years back, it was no surprise that they found a common purpose.

Both Agmoni and Komoni knew that tracking technology was too costly to be used across every type of cargo. “Unless it’s valuable, perishable cargo,” says Agmoni, “nobody will want to just go and track every single container, every single shipment — especially considering a few years ago, when it was really expensive.” Agmoni and Komoni knew they needed to develop a more affordable solution that could provide data that was actually relevant to all types of general cargo shipments.

The Proof of Concept

In the years following the MIT event, Agmoni and Komoni explored alternatives that could offer the value they sought at a price point shippers would accept. The first step in their experiment was to design a proof of concept. The team at Maersk took on the task, beginning with outreach. “We went to customers, we brought them in, we started some discussions,” says Agmoni. “We looked into what could help them improve their supply chains.” Over the course of their research, customers commonly expressed frustration with transit times: They were unreliable, inaccurate, and did little to help them plan around the situation at hand. That’s when Agmoni had an idea. Instead of tracking each individual shipment — which, as customers were saying, wasn’t providing the information they actually needed — they could also track aggregated data.

The Maersk Innovation Center designed a proof of concept for a means of keeping tabs on thousands of shipments without having to view each one individually. In other words, they would track aggregated data from thousands of shipments, starting with a route from Los Angeles to Memphis. Tive, meanwhile, started building the hardware and the backend technology. Once the product was ready, Tive ensured that all of the trackers were properly installed at the warehouse in Los Angeles, and that each of them was linked to the appropriate shipment and order.

From there, Tive’s data science and data analytics teams, with input from Maersk, went to work analyzing the data from the trackers — looking at which algorithms they wanted to run on the dataset to figure out what insights they could gain. “Working together, we were able to find some really interesting things,” says Komoni. In the end, the higher-level view yielded surprising insights.

The Results

On the drive from Los Angeles to Memphis, there are two main routes from which truckers can choose: a southern route, which runs near the U.S.–Mexico border, and a northern route, which is a slightly more direct line from point A to point B. On all navigation systems, the northern route is estimated to be two hours faster than its counterpart. But when Maersk and Tive started looking at the aggregated data, they learned something that they couldn’t have known from individualized tracking information.

“When we started to look at the aggregated data,” says Agmoni, “we found out that the northern route is taking six days, plus or minus two — so four to eight days.” Though Google Maps will estimate the drive to be 32 hours, it’s expected that drivers will need to stop and rest along the way, stretching the trip out into several days. But when they looked at the presumably slower, southern route, the average driver was completing the trip in four to six days. Not only was this faster, but the driving estimate was more precise.

To understand why this was, they had to go back to the data. Using a collection of tools and graphs that they’d custom built for this purpose, Tive began to calculate the idle times along each route. “What we said is, ‘why don’t we figure out where the trucks are stopping for the longest time?’” says Komoni. “And then we mapped that out, and we saw these big red spots on areas where they’re stopping on the southern route and also where they’re stopping on the northern route.

”It quickly became clear from the data that drivers on the northern route were stopping much more frequently than on the southern route. “We couldn’t know why they’d do that,” says Agmoni, “so we had to call some of them. And we learned a very interesting thing.”

After speaking with some of the drivers, they learned that rest stops on the northern route are small and, more often than not, completely full. “It’s a very busy route,” says Agmoni. “They don’t trust that there will be space at the rest stop when they’ve reached the maximum hours of driving. So they start looking two or three stops beforehand. If there is one, they stop; if not, they’ll go to the next on the route.” On the southern route, however, the stops are more reliable. Drivers can trust that when they need to make a stop, there will be space for them to do so — allowing them to maximize the number of hours that they can drive, and shortening the total transit time altogether.“

That really helped us to change the way we route things. You can’t find this information if you follow one shipment at a time; you really need the aggregated data,” says Agmoni.

“It's great insight,” Komoni adds, “because now you finally have value that you can sell. You can justify the cost on all types of general cargo — and not just on time-sensitive, temperature-sensitive, high-value shipments.”

Maersk and Tive’s proof of concept was a clear success, allowing them to move forward in the development of their product.

The Solution

Using what they learned, Maersk has since developed a new product called Ocean + Transload, a solution for cargo transportation that improves transit time variability, reduces carbon emissions, and helps minimize detention and demurrage charges.

“It’s a replacement for the inland port solutions that carriers sell,” says Agmoni. Typically with intermodal travel, carriers see a lot of fluctuation in transit times. “The intermodal connection of international containers is not to the level of our customer expectation,” he says.

With Ocean + Transload, they can take containers and translate them into trailers by putting them back on the rail or on the road. “And of course we are adding visibility trackers to all those shipments at no extra cost — to provide our customers with a solution that first, gives them a much more precise time, and second, sends alerts way in advance when the shipment is about to arrive.” Armed with this increased visibility into their shipments, customers no longer need to follow up to receive updates on the status of their shipment. Updates come to them directly.

According to Komoni, the uniformity of the data made possible by the collaboration was a central component to the solution’s success. “I think that uniformity is the real value that allows Maersk to do aggregated analytics and understand insights for their customers. There is tremendous value in uniformity,” he says.

What started as a shared frustration at the lack of tracking information on general cargo shipments resulted in not only a successful collaboration between two companies — it also provided a much-needed advancement in tracking technology and shipping analytics that will help companies make smarter and more cost-efficient decisions across the supply chain.

RELATED CONTENT

RELATED VIDEOS

Five Critical Challenges Facing Pharma Supply Chains

Subscribe to our daily newsletter.

Timely, incisive articles delivered directly to your inbox.

Popular Stories

How Businesses Can Cut Supply Chain Costs Without Jeopardizing Long-Term Growth

Fashion Brands Make Earth Day Commitment to Preserve Endangered Forests

Why Planning Isn’t Enough to Achieve True Operational Excellence

Podcast | What’s It Take to Be a Great Chief Supply Chain Officer?

U.K. Brexit Import Checks Delayed, Causing Confusion

Digital edition.

2024 Supply Chain Management Resource Guide: There's Only One Way Off a Burning Platform

Case studies, recycled tagging fasteners: small changes make a big impact.

Enhancing High-Value Electronics Shipment Security with Tive's Real-Time Tracking

Moving Robots Site-to-Site

Jll finds perfect warehouse location, leading to $15m grant for startup, robots speed fulfillment to help apparel company scale for growth.

COMMENTS

In this context, Walmart, the world's largest retailer, has demonstrated a highly successful and integrated Walmart supply chain, propelling its growth and dominance in the retail industry. This case study aims to delve into the significance of supply chain capability for enhancing a company's competitiveness and how it serves as a ...

The Walmart: Supply Chain Management case study discusses the cost-saving strategy of the company and its supply chain management strategy. It focuses on how the company manages its supply chain in comparison with its competitors. P. Fraser Johnson and Ken Mark Harvard Business Review (W19317-PDF-ENG) July 08, 2019. Case questions answered:

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to compare Walmart's source of competitiveness with those of other retailers-both online including Amazon.com and traditional brick-and-mortar retailers, such as Target-to develop insights into the ...

Walmart was the first company in the world to use barcodes on 100% of its products, way back in 1983. In 2015 alone it spent $10.5 billion on IT, a lot even for a company that booked $486 billion of revenue that year. And nothing has changed. In 2021, Walmart CFO Brett M. Biggs said, "From a position of great strength, we're now going to ...

Walmart Supply Chain Management ( Case study) Walmart has highly effective supply chain management practices that have contributed significantly to its success. It uses procurement strategies like direct sourcing from manufacturers and vendor managed inventory. Logistically, it employs cross-docking and a hub-and-spoke distribution model.

Abstract. Walmart is one of the largest retailers in the world, and its supply chain system is affected. Through the analysis of Walmart's business and technology, this paper discusses the reasons ...

Walmart introduced concepts that are now industry standards. Many of these concepts come directly from the way the company builds and operates its supply cha...

Centralization: Walmart has centralized its supply chain operations. This has allowed the company to improve efficiency and coordination. Technology: Walmart has invested heavily in technology to improve its supply chain. This includes the use of RFID tags, computer systems, and big data analytics. Collaboration: Walmart works closely with its ...

Case questions answered: Describe Wal-Mart's supply chain and how it integrates with other elements of its strategy. Discuss how Wal-Mart's supply chain strategy metrics changed from 2000 to 2006 based on the company's percentage of assets committed to inventory, inventory turnover, and weeks of supply. Compare the performance of Wal-Mart ...

This operations management case study focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to compare Walmart's source of competitiveness with those of other retailers—both online including Amazon and traditional brick-and-mortar retailers, such as Target ...