How it works

For Business

Join Mind Tools

Article • 8 min read

8D Problem Solving Process

Solving major problems in a disciplined way.

By the Mind Tools Content Team

(Also known as Global 8D Problem Solving)

When your company runs into a major problem, you need to address it quickly. However, you also need to deal with it thoroughly and ensure that it doesn't recur – and this can take a lot of effort and elapsed time.

The 8D Problem Solving Process helps you do both of these seemingly-contradictory things, in a professional and controlled way. In this article, we'll look at the 8D Problem Solving Process, and we'll discuss how you can use it to help your team solve major problems.

Origins of the Tool

The Ford Motor Company® developed the 8D (8 Disciplines) Problem Solving Process, and published it in their 1987 manual, "Team Oriented Problem Solving (TOPS)." In the mid-90s, Ford added an additional discipline, D0: Plan. The process is now Ford's global standard, and is called Global 8D.

Ford created the 8D Process to help teams deal with quality control and safety issues; develop customized, permanent solutions to problems; and prevent problems from recurring. Although the 8D Process was initially applied in the manufacturing, engineering, and aerospace industries, it's useful and relevant in any industry.

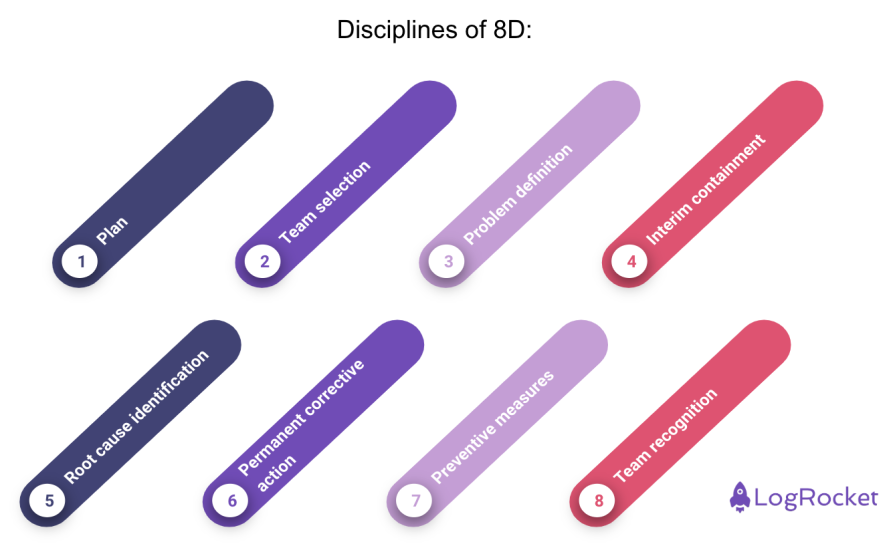

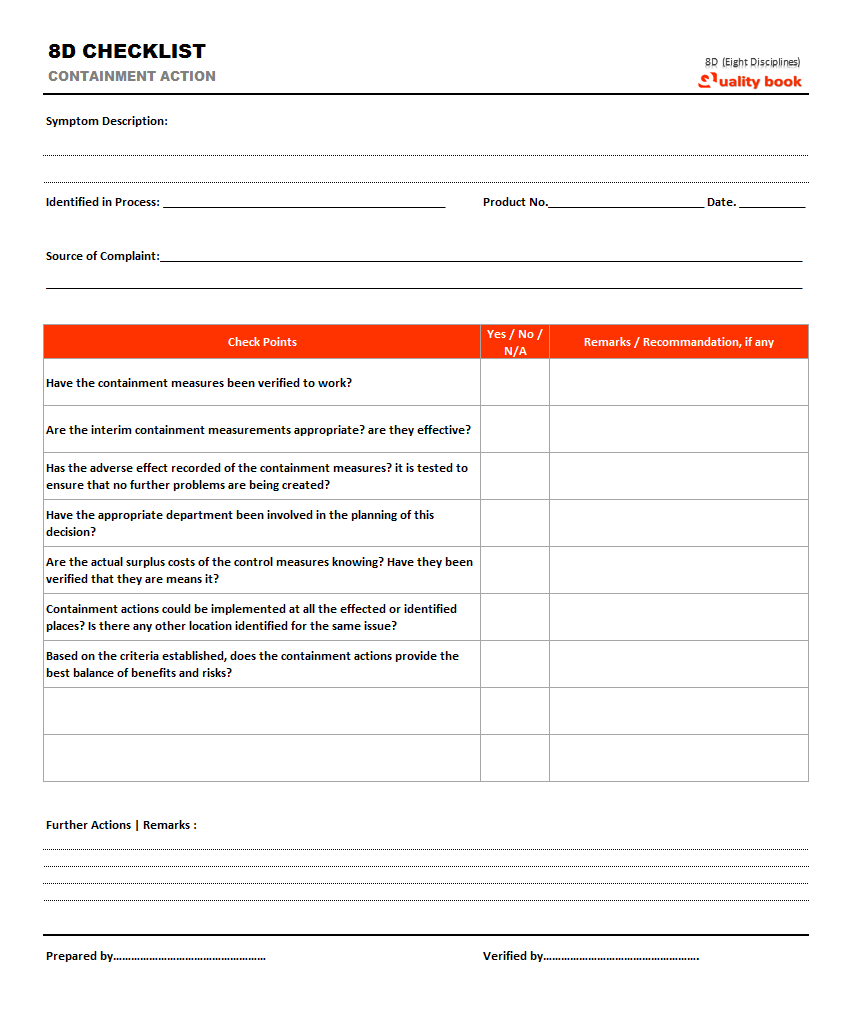

The eight disciplines are shown in figure 1, below:

Figure 1: The 8D Problem Solving Process

The 8D Process works best in teams tasked with solving a complex problem with identifiable symptoms. However, you can also use this process on an individual level, as well.

Applying the Tool

To use the 8D Process, address each of the disciplines listed below, in order. Take care not to skip steps, even when time is limited; the process is only effective when you follow every step.

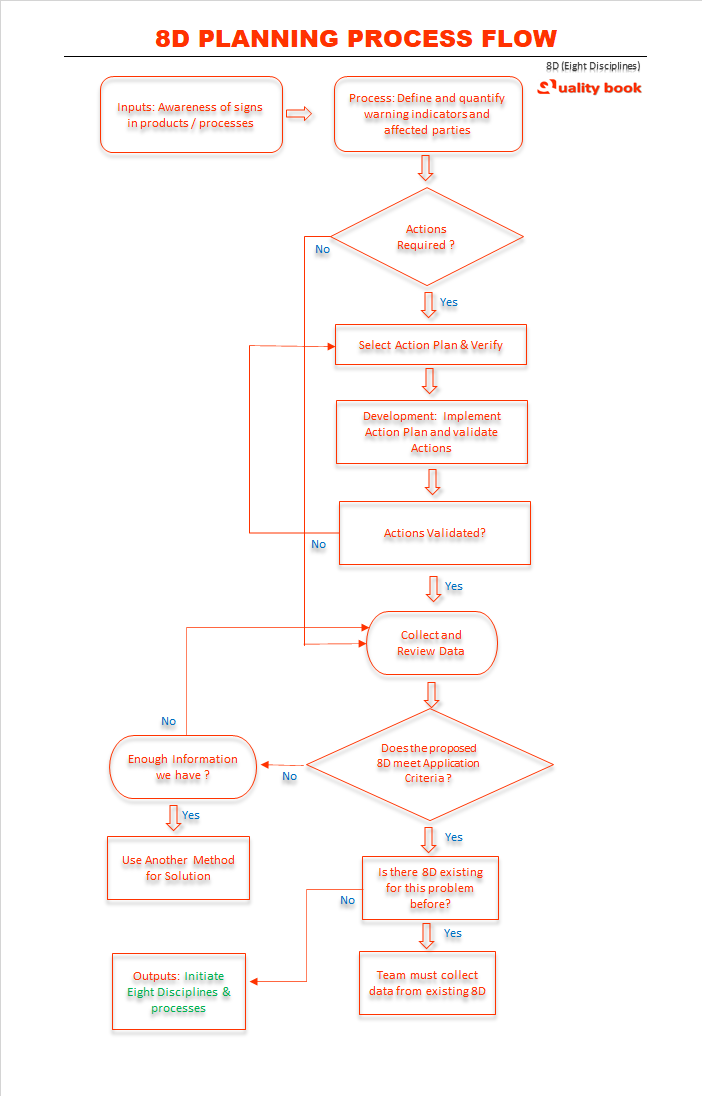

Discipline 0: Plan

Before you begin to assemble a team to address the problem, you need to plan your approach. This means thinking about who will be on the team, what your time frame is, and what resources you'll need to address the problem at hand.

Discipline 1: Build the Team

You should aim to put together a team that has the skills needed to solve the problem, and that has the time and energy to commit to the problem solving process.

Keep in mind that a diverse team is more likely to find a creative solution than a team of people with the same outlook (although if outlooks are too diverse, people can spend so much time disagreeing that nothing gets done).

Create a team charter that outlines the team's goal and identifies each person's role. Then, do what you can to build trust and get everyone involved in the process that's about to happen.

If your team is made up of professionals who haven't worked together before, consider beginning with team-building activities to ensure that everyone is comfortable working with one another.

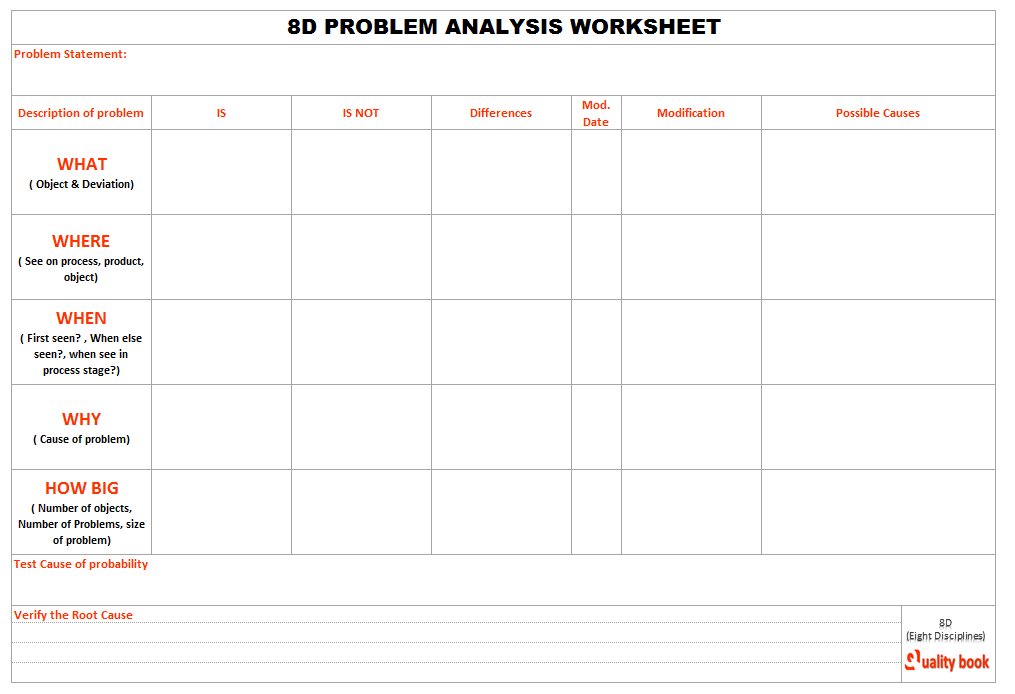

Discipline 2: Describe the Problem

Once your team has settled in, describe the problem in detail. Specify the who, what, when, where, why, how, and how many; and use techniques like CATWOE and the Problem-Definition Process to ensure that you're focusing on the right problem.

Start by doing a Risk Analysis – if the problem is causing serious risks, for example, to people's health or life, then you need to take appropriate action. (This may include stopping people using a product or process until the problem is resolved.)

If the problem is with a process, use a Flow Chart , Swim Lane Diagram , or Storyboard to map each step out; these tools will help your team members understand how the process works, and, later on, think about how they can best fix it.

Discovering the root cause of the problem comes later in the process, so don't spend time on this here. Right now, your goal is to look at what's going wrong and to make sure that your team understands the full extent of the problem.

Discipline 3: Implement a Temporary Fix

Once your team understands the problem, come up with a temporary fix. This is particularly important if the problem is affecting customers, reducing product quality, or slowing down work processes.

Harness the knowledge of everyone on the team. To ensure that each person's ideas are heard, consider using brainstorming techniques such as Round Robin Brainstorming or Crawford's Slip Writing Method , alongside more traditional team problem solving discussions.

Once the group has identified possible temporary fixes, address issues such as cost, implementation time, and relevancy. The short-term solution should be quick, easy to implement, and worth the effort.

Discipline 4: Identify and Eliminate the Root Cause

Once your temporary fix is in place, it's time to discover the root cause of the problem.

Conduct a Cause and Effect Analysis to identify the likely causes of the problem. This tool is useful because it helps you uncover many possible causes, and it can highlight other problems that you might not have been aware of. Next, apply Root Cause Analysis to find the root causes of the problems you've identified.

Once you identify the source of the problem, develop several permanent solutions to it.

If your team members are having trouble coming up with viable permanent solutions, use the Straw Man Concept to generate prototype solutions that you can then discuss, tear apart, and rebuild into stronger solutions.

Discipline 5: Verify the Solution

Once your team agrees on a permanent solution, make sure that you test it thoroughly before you fully implement it, in the next step.

- Conducting a Failure Mode and Effects Analysis (FMEA) to spot any potential problems.

- Using Impact Analysis to make sure that there will be no unexpected future consequences.

- Using Six Thinking Hats to examine the fix from several different emotional perspectives.

Last, conduct a Blind Spot Analysis to confirm that you and your team haven't overlooked a key factor, or made an incorrect assumption about this solution.

Discipline 6: Implement a Permanent Solution

Once your team reaches a consensus on the solution, roll your fix out. Monitor this new solution closely for an appropriate period of time to make sure that it's working correctly, and ensure that there are no unexpected side effects.

Discipline 7: Prevent the Problem From Recurring

When you're sure that the permanent solution has solved the problem, gather your team together again to identify how you'll prevent the problem from recurring in the future.

You might need to update your organization's standards, policies, procedures, or training manual to reflect the new fix. You'll likely also need to train others on the new process or standard. Finally, you'll need to consider whether to change your management practices or procedures to prevent a recurrence.

Discipline 8: Celebrate Team Success

The last step in the process is to celebrate and reward your team's success . Say "thank you" to everyone involved, and be specific about how each person's hard work has made a difference. If appropriate, plan a party or celebration to communicate your appreciation.

Before the team disbands, conduct a Post-Implementation Review to analyze whether your solution is working as you thought, and to improve the way that you solve problems in the future.

In the late 1980s, Ford Motor Company developed the 8D (8 Disciplines) Problem Solving Process to help manufacturing and engineering teams diagnose, treat, and eliminate quality problems. However, teams in any industry can use this problem solving process.

The eight disciplines are:

- Build the Team.

- Describe the Problem.

- Implement a Temporary Fix.

- Identify and Eliminate the Root Cause.

- Verify the Solution.

- Implement a Permanent Solution.

- Prevent the Problem From Recurring.

- Celebrate Team Success.

The 8D Problem Solving Process is best used with a team solving complex problems; however, individuals can also use it to solve problems on their own.

Ford is a registered trademark of the Ford Motor Company: https://www.ford.com/

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Book Insights

Fail Better: Design Smart Mistakes and Succeed Sooner

Anjali Sastry and Kara Penn

Maslow's Hierarchy of Needs

A Model for Supporting Your People Toward Self-Actualization

Add comment

Comments (0)

Be the first to comment!

Team Management

Learn the key aspects of managing a team, from building and developing your team, to working with different types of teams, and troubleshooting common problems.

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

SWOT Analysis

How to Build a Strong Culture in a Distributed Team

Mind Tools Store

About Mind Tools Content

Discover something new today

Top tips for delegating.

Delegate work to your team members effectively with these top tips

Ten Dos and Don'ts of Change Conversations

Tips for tackling discussions about change

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

6 traits of a true professional video.

Video Transcript

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

.css-s5s6ko{margin-right:42px;color:#F5F4F3;}@media (max-width: 1120px){.css-s5s6ko{margin-right:12px;}} Discover how today’s most successful IT leaders stand out from the rest. .css-1ixh9fn{display:inline-block;}@media (max-width: 480px){.css-1ixh9fn{display:block;margin-top:12px;}} .css-1uaoevr-heading-6{font-size:14px;line-height:24px;font-weight:500;-webkit-text-decoration:underline;text-decoration:underline;color:#F5F4F3;}.css-1uaoevr-heading-6:hover{color:#F5F4F3;} .css-ora5nu-heading-6{display:-webkit-box;display:-webkit-flex;display:-ms-flexbox;display:flex;-webkit-align-items:center;-webkit-box-align:center;-ms-flex-align:center;align-items:center;-webkit-box-pack:start;-ms-flex-pack:start;-webkit-justify-content:flex-start;justify-content:flex-start;color:#0D0E10;-webkit-transition:all 0.3s;transition:all 0.3s;position:relative;font-size:16px;line-height:28px;padding:0;font-size:14px;line-height:24px;font-weight:500;-webkit-text-decoration:underline;text-decoration:underline;color:#F5F4F3;}.css-ora5nu-heading-6:hover{border-bottom:0;color:#CD4848;}.css-ora5nu-heading-6:hover path{fill:#CD4848;}.css-ora5nu-heading-6:hover div{border-color:#CD4848;}.css-ora5nu-heading-6:hover div:before{border-left-color:#CD4848;}.css-ora5nu-heading-6:active{border-bottom:0;background-color:#EBE8E8;color:#0D0E10;}.css-ora5nu-heading-6:active path{fill:#0D0E10;}.css-ora5nu-heading-6:active div{border-color:#0D0E10;}.css-ora5nu-heading-6:active div:before{border-left-color:#0D0E10;}.css-ora5nu-heading-6:hover{color:#F5F4F3;} Read the report .css-1k6cidy{width:11px;height:11px;margin-left:8px;}.css-1k6cidy path{fill:currentColor;}

- Project management |

- What is 8D? A template for efficient pr ...

What is 8D? A template for efficient problem-solving

How you respond when problems arise is one of the most defining qualities of a manager. Luckily, there are tools you can use to master problem-solving. The 8D method of problem-solving combines teamwork and basic statistics to help you reach a logical solution and prevent new issues from arising.

You’ve spent months overseeing the development of your company's newest project. From initiation, planning, and execution, you’re confident this may be your best work yet.

Until the feedback starts rolling in.

There’s no sugar-coating it—things don’t always go as planned. But production or process issues are hardly a signal to throw in the towel. Instead, focus on honing your problem-solving skills to find a solution that keeps it from happening again.

The 8D method of problem solving emphasizes the importance of teamwork to not only solve your process woes but prevent new ones from occurring. In this guide, we’ll break down what 8D is, how to use this methodology, and the benefits it can give to you and your team. Plus, get an 8D template to make solving your issue easier.

What is 8D?

The eight disciplines (8D) method is a problem-solving approach that identifies, corrects, and eliminates recurring problems. By determining the root causes of a problem, managers can use this method to establish a permanent corrective action and prevent recurring issues.

How do you use the 8D method?

The 8D method is a proven strategy for avoiding long-term damage from recurring problems. If you’re noticing issues in your workflow or processes, then it’s a good time to give this problem-solving method a try.

To complete an 8D analysis, follow “the eight disciplines” to construct a statistical analysis of the problem and determine the best solution.

The eight disciplines of problem-solving

8D stands for the eight disciplines you will use to establish an 8D report. As you may notice, this outline starts with zero, which makes nine total disciplines. The “zero stage” was developed later as an initial planning stage.

To illustrate these steps, imagine your organization experienced a decline in team innovation and productivity this past year. Your stakeholders have noticed and want to see changes implemented within the next six months. Below, we’ll use the 8D process to uncover a morale-boosting solution.

![8d discipline problem solving [inline illustration] D8 problem solving approach (infographic)](https://assets.asana.biz/transform/6ab7c188-3258-4d2e-afe6-9a4a084cc09f/inline-productivity-8d-template-1-2x?io=transform:fill,width:2560&format=webp)

D0: Prepare and plan

Before starting the problem-solving process, evaluate the problem you want to solve. Understanding the background of the problem will help you identify the root cause in later steps.

Collect information about how the problem has affected a process or product and what the most severe consequences may be. Planning can include:

Gathering data

Determining the prerequisites for solving the problem

Collecting feedback from others involved

![8d discipline problem solving [inline illustration] D0 Planning (example)](https://assets.asana.biz/transform/abc3621d-e1ae-47ff-b731-0ee38cff99e9/inline-productivity-8d-template-2-2x?io=transform:fill,width:2560&format=webp)

If we look back at our example, you may want to figure out whether this decline in morale is organization-wide or only applies to a few departments. Consider interviewing a few employees from different departments and levels of management to gain some perspective. Next, determine what knowledge and skills you will need to solve this lapse in productivity.

D1: Form your team

Create a cross-functional team made up of people who have knowledge of the various products and workflows involved. These team members should have the skills needed to solve the problem and put corrective actions in place.

Steps in this discipline may include:

Appointing a team leader

Developing and implementing team guidelines

Determining team goals and priorities

Assigning individual roles

Arranging team-building activities

![8d discipline problem solving [inline illustration] D1 Team members (example)](https://assets.asana.biz/transform/51986017-5150-4dd4-940c-252cd0eb8ba5/inline-productivity-8d-template-3-2x?io=transform:fill,width:2560&format=webp)

From our example, a solid team would consist of people with first-hand experience with the issues—like representatives from all departments and key people close to workshop-level work. You may also want to pull someone in from your HR department to help design and implement a solution. Most importantly, make sure the people you choose want to be involved and contribute to the solution.

D2: Identify the problem

You may have a good understanding of your problem by now, but this phase aims to break it down into clear and quantifiable terms by identifying the five W’s a and two H’s (5W2H):

Who first reported the problem?

What is the problem about?

When did it occur and how often?

Where did it occur (relating to the sector, supplier, machine, or production line involved)?

Why is solving the problem important?

How was the problem first detected?

How many parts/units/customers are affected?

![8d discipline problem solving [inline illustration] D2 Problem statement & description (example)](https://assets.asana.biz/transform/9825ecd6-2bd3-4559-a68c-b1ae8aca2e52/inline-productivity-8d-template-4-2x?io=transform:fill,width:2560&format=webp)

Use your team’s insights to answer these questions. From our example, your team may conclude that:

Employees feel overwhelmed with their current workload.

There is no real structure or opportunity to share new ideas.

Managers have had no training for meetings or innovation settings.

Disgruntled employees know they can achieve more—and want to achieve more—even if they seem disengaged.

Once you answer these questions, record an official problem statement to describe the issue. If possible, include photos, videos, and diagrams to ensure all parties have a clear understanding of the problem. It may also help to create a flowchart of the process that includes various steps related to the problem description.

D3: Develop an interim containment plan

Much like we can expect speedy first aid after an accident, your team should take immediate actions to ensure you contain the problem—especially if the problem is related to customer safety.

An interim containment plan will provide a temporary solution to isolate the problem from customers and clients while your team works to develop a permanent corrective action. This band-aid will help keep your customers informed and safe—and your reputation intact.

![8d discipline problem solving [inline illustration] D3 Interim containment action (example)](https://assets.asana.biz/transform/d6279c36-ccc6-4de3-89d2-f221632a1059/inline-productivity-8d-template-5-2x?io=transform:fill,width:2560&format=webp)

Because your findings revealed workers were overworked and managers lacked training, your team suggests scheduling a few mandatory training sessions for leaders of each department covering time and stress management and combating burnout . You may also want to have a presentation outlining the topics of this training to get key managers and stakeholders interested and primed for positive upcoming changes.

D4: Verify root causes and escape points

Refer back to your findings and consult with your team about how the problem may have occurred. The root cause analysis involves mapping each potential root cause against the problem statement and its related test data. Make sure to test all potential causes—fuzzy brainstorming and sloppy analyses may cause you to overlook vital information.

![8d discipline problem solving [inline illustration] D4 Root cause & escape points (example)](https://assets.asana.biz/transform/301717c6-0434-4c88-addf-d500dc23ae87/inline-productivity-8d-template-6-2x?io=transform:fill,width:2560&format=webp)

In our example, focus on the “why” portion of the 5W2H. You and your team identify six root causes:

Managers have never had any training

There is a lack of trust and psychological safety

Employees don’t understand the objectives and goals

Communication is poor

Time management is poor

Employees lack confidence

In addition to identifying the root causes, try to pinpoint where you first detected the problem in the process, and why it went unnoticed. This is called the escape point, and there may be more than one.

D5: Choose permanent corrective actions

Work with your team to determine the most likely solution to remove the root cause of the problem and address the issues with the escape points. Quantitatively confirm that the selected permanent corrective action(s) (PCA) will resolve the problem for the customer.

Steps to choosing a PCA may include:

Determining if you require further expertise

Ensuring the 5W2Hs are defined correctly

Carrying out a decision analysis and risk assessment

Considering alternative measures

Collecting evidence to prove the PCA will be effective

![8d discipline problem solving [inline illustration] D5 Permanent corrective action (example)](https://assets.asana.biz/transform/53509966-18dd-4bb4-88a1-c7ca940fde3f/inline-productivity-8d-template-7-2x?io=transform:fill,width:2560&format=webp)

Your team decides to roll out the training used in the interim plan to all employees, with monthly company-wide workshops on improving well-being. You also plan to implement meetings, innovation sessions, and team-coaching training for managers. Lastly, you suggest adopting software to improve communication and collaboration.

D6: Implement your corrective actions

Once all parties have agreed on a solution, the next step is to create an action plan to remove the root causes and escape points. Once the solution is in effect, you can remove your interim containment actions.

After seeing success with the training in the interim phase, your stakeholders approve all of your team’s proposed PCAs. Your representative from HR also plans to implement periodic employee wellness checks to track employee morale .

![8d discipline problem solving [inline illustration] D6 PCA implementation plan (example)](https://assets.asana.biz/transform/ca68af4a-afa7-4be4-93cb-8a8321eb5172/inline-productivity-8d-template-8-2x?io=transform:fill,width:2560&format=webp)

To ensure your corrective action was a success, monitor the results, customer, or employee feedback over a long period of time and take note of any negative effects. Setting up “controls” like employee wellness checks will help you validate whether your solution is working or more needs to be done.

D7: Take preventive measures

One of the main benefits of using the 8D method is the improved ability to identify necessary systematic changes to prevent future issues from occurring. Look for ways to improve your management systems, operating methods, and procedures to not only eliminate your current problem, but stop similar problems from developing later on.

![8d discipline problem solving [inline illustration] D7 Preventive measure (example)](https://assets.asana.biz/transform/cdd7b133-fb80-4db7-8935-1285a6b62b69/inline-productivity-8d-template-9-2x?io=transform:fill,width:2560&format=webp)

Based on our example, the training your team suggested is now adopted in the new manager onboarding curriculum. Every manager now has a “meeting system” that all meetings must be guided by, and workloads and projects are managed as a team within your new collaboration software . Innovation is improving, and morale is at an all-time high!

D8: Celebrate with your team

The 8D method of problem-solving is impossible to accomplish without dedicated team members and first-class collaboration. Once notes, lessons, research, and test data are documented and saved, congratulate your teammates on a job well done! Make an effort to recognize each individual for their contribution to uncovering a successful solution.

![8d discipline problem solving [inline illustration] 8D Team congratulations & reward (example)](https://assets.asana.biz/transform/d2055965-bf3d-4bf4-a1ea-a0a7c4bf8a32/inline-productivity-8d-template-10-2x?io=transform:fill,width:2560&format=webp)

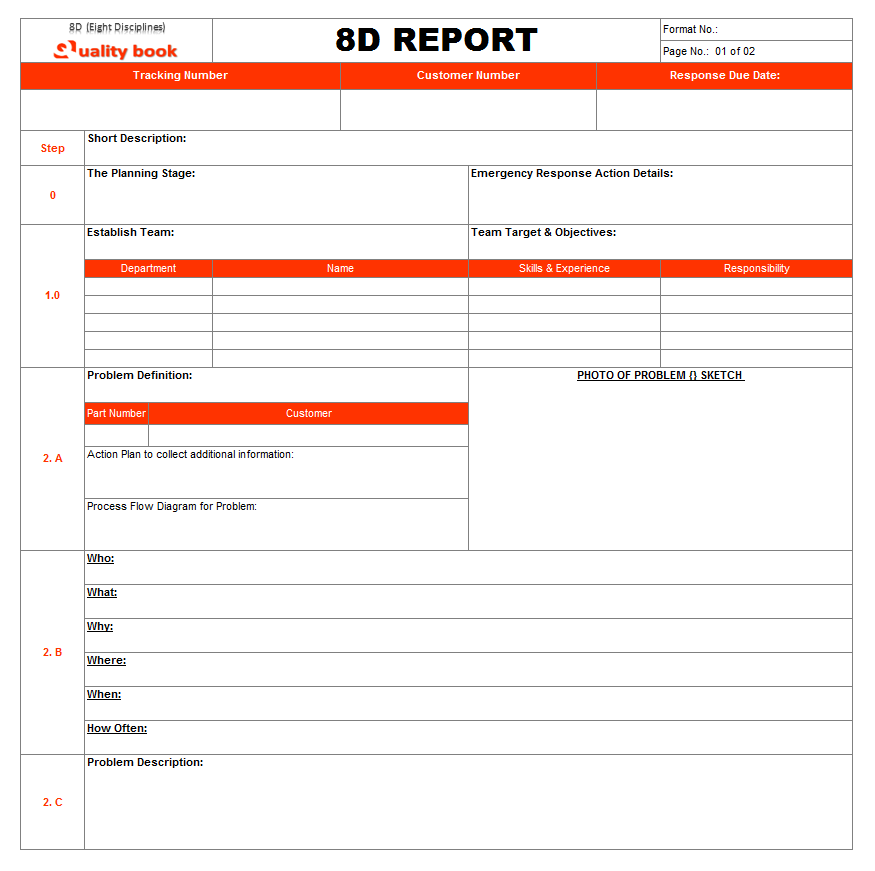

8D report template and example

Check out our 8D report template below to help you record your findings as you navigate through the eight disciplines of problem solving. This is a formal report that can be used as a means of communication within companies, which makes for transparent problem-solving that you can apply to the entire production or process chain.

Benefits of using the 8D method

The 8D method is one of the most popular problem-solving strategies for good reason. Its strength lies in teamwork and fact-based analyses to create a culture of continuous improvement —making it one of the most effective tools for quality managers. The benefits of using the 8D method include:

Improved team-oriented problem-solving skills rather than relying on an individual to provide a solution

Increased familiarity with a problem-solving structure

A better understanding of how to use basic statistical tools for problem-solving

Open and honest communication in problem-solving discussions

Prevent future problems from occurring by identifying system weaknesses and solutions

Improved effectiveness and efficiency at problem-solving

Better collaboration = better problem solving

No matter how good a manager you are, production and process issues are inevitable. It’s how you solve them that separates the good from the great. The 8D method of problem solving allows you to not only solve the problem at hand but improve team collaboration, improve processes, and prevent future issues from arising.

Try Asana’s project management tool to break communication barriers and keep your team on track.

Related resources

How Asana uses work management to optimize resource planning

Understanding dependencies in project management

Program manager vs. project manager: Key differences to know

Critical path method: How to use CPM for project management

Advisory boards aren’t only for executives. Join the LogRocket Content Advisory Board today →

- Product Management

- Solve User-Reported Issues

- Find Issues Faster

- Optimize Conversion and Adoption

An overview of the 8D problem-solving method

The 8D problem-solving method is a powerful tool in product management. It’s designed to help product managers tackle issues systematically and enhance product quality. This method follows eight steps in total, hence the name 8D.

The steps range from identifying problems to implementing long-term solutions. Today you’ll explore how you can effectively apply 8D to your products. You’ll also learn about the benefits of using this approach and analyze some real case studies.

What is 8D?

The 8D problem-solving method is designed to address and resolve problems by identifying, correcting, and eliminating recurring issues.

It involves eight different steps:

- Plan — Prepare for the problem-solving process

- Team selection — Assemble a team with the necessary knowledge and skills

- Problem definition — Clearly define the problem and its impact

- Interim containment action — Implement temporary measures to contain the problem

- Root cause identification — Identify the underlying cause(s) of the problem

- Permanent corrective action — Develop and implement a solution to address the root cause

- Preventive measures — Take steps to prevent the recurrence of the problem

- Team recognition — Acknowledge and reward the team’s efforts in resolving the issue

These steps focus on root cause analysis, preventive measures, and long-term solution implementation. The end goal is to improve product quality and operational efficiency.

The eight disciplines of 8D

The eight disciplines of the 8D method represent a comprehensive approach to solve problems within an organization. Each discipline is designed to guide teams through the process at each stage. Here’s a deeper look into each stage:

This initial step involves preparing for the problem-solving process. The goal here is to understand the problem’s magnitude and set up objectives. It’s about getting ready to tackle the issue systematically.

Team selection

In this step, a cross-functional team is formed. The team should consist of individuals with the necessary knowledge, skills, and experience to address the problem effectively. The team works together throughout the 8D process.

Problem definition

Next, the team has to describe the issue in specific terms. The goal here is to understand the impact and scope of the complication. A well-defined problem is easier to solve.

Interim containment

In the process of finding a solution, temporary measures are taken to contain the problem and prevent it from worsening. This reduces further damage or impact to the involved operations.

Root cause identification

In this phase, the team uses various tools and techniques to identify the underlying cause of the problem. An understanding of the root cause is essential for developing an effective, lasting solution.

Permanent corrective action

With the root cause identified, the team moves to develop a permanent corrective action plan to resolve the issue. Now, the team needs to choose the best solution, implement it, and monitor its effectiveness. This analysis will ensure that the problem is truly resolved.

Over 200k developers and product managers use LogRocket to create better digital experiences

Preventive measures

With such vast processes, there is always a possibility of the problem recurring. To resolve this, the team identifies and implements measures that address the root cause. There might be a need for changes to different aspects of the overall approach.

Team recognition

The final stage focuses on acknowledging and rewarding the team’s efforts. Recognizing the team’s hard work and success in resolving the issue is important for morale. It also promotes a culture of continuous improvement.

By following these eight disciplines, product managers can solve problems more effectively. The other benefit is that it builds a proactive culture that addresses issues before they escalate.

Applying 8D in product management

Applying the 8D problem-solving method in product management involves leveraging its structured approach. This helps you eliminate problems and process improvement initiatives.

Problem identification

The 8D process begins with gathering data and feedback to quickly identify potential issues. After that, a diverse team from various departments works together to uncover issues. And finally, the team solves the problems efficiently.

Once a problem is spotted, quick fixes are applied to limit its impact. Simultaneously, you explore root causes of an issue using methods like the Five Whys . The final step is to implement the solution based on these insights. Occasionally, redesigns or process upgrades are also used to resolve the issue thoroughly.

Elimination

To eliminate recurring problems, it’s crucial to establish preventive measures. Several steps support the main goal of elimination including process adjustments, quality control improvements, and updates to design standards.

The insights gathered from each 8D cycle help with continuous improvement. It also aids in formulating strategies to avert future issues.

Benefits of the 8D method

The main benefit of using the 8D method is its impact on teamwork and continuous improvement. The more obvious benefits focus on root cause analysis and prevention of issues:

- Enhanced quality control

- Efficient problem resolution

- Systematic and thorough approach

- Teamwork and knowledge sharing

- Focus on root cause analysis

- Reduced recurrence of issues

- Cost reduction

- Improved customer satisfaction

The systematic approach to address issues ensures that no effort goes to waste. Eventually, it helps the teams to quickly propose long-term solutions to a range of problem patterns.

Challenges in implementing 8D

The 8D problem-solving method is extremely valuable when used in the right manner. However, there can be challenges at every stage of this process. Because of this, it’s beneficial for you to have an understanding of how to quickly identify these challenges.

These include:

- Resistance to change among team members

- Insufficient teamwork and collaboration

- Lack of training on the 8D methodology

- Difficulties in data collection and analysis

How to solve them?

- Clearly communicate benefits to overcome resistance

- Foster collaboration and teamwork among participants

- Provide targeted training on the 8D process

- Encourage data analysis for effective problem-solving

For a deeper understanding, let’s take a look at two case studies of how the 8D process can enhance the product management workflow.

Real-life examples of 8D

A leading tech company, (similar to Apple) faced public backlash over smartphones overheating and reduced battery life. In this context, the 8D method helped to quickly identify and contain the issues.

The root cause analysis helped it track the problem back to a battery design flaw. Collaborative efforts with the battery supplier led to a redesigned battery and an update to the operating system. This not only resolved the issue but also restored consumer trust. Eventually, the brand’s reputation for quality was restored.

Similarly, a major automaker found a software glitch in its driver-assistance systems. This issue was risking driver safety. Using the 8D method, it pinpointed outdated algorithms as the root cause. The solution was simple, it issued a software update and enhanced its development processes.

Both of these examples are evidence of how the 8D method can be utilized to prevent complications efficiently.

Key takeaways

In wrapping up, it’s clear that this approach is more than just a procedure. Think of it as a strategic framework designed for the product manager. The 8D method equips you with a robust toolkit for addressing and preempting issues, systematically.

On top of that it helps you to:

- Promote teamwork and continuous improvement

- Reduce problem recurrence through root cause analysis

- Overcome implementation challenges with effective communication

Feel free to comment with any questions you may have!

Featured image source: IconScout

LogRocket generates product insights that lead to meaningful action

Get your teams on the same page — try LogRocket today.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Facebook (Opens in new window)

- #agile and scrum

- #project management

Stop guessing about your digital experience with LogRocket

Recent posts:.

Leader Spotlight: The impact of macroeconomic trends on product roles, with Lori Edwards

Lori Edwards, Director of Product at Niche, discusses challenges with the transition from an individual contributor to a people manager.

Techniques for building rapport in professional settings

Effective rapport fosters trust, facilitates communication, and creates a foundation for successful collaboration and conflict resolution.

Embracing product-led growth: Principles, strategies, and metrics

The core of PLG relies on reducing time to value and relentlessly improving the user experience by creating multiple a-ha moments.

Leader Spotlight: The digital transformation of beauty school curriculum, with Corina Santoro

Corina Santoro talks about how her team made the prediction that customers in the beauty school industry are going to prefer digital learning.

Leave a Reply Cancel reply

8D Problem Solving: Comprehensive Breakdown and Practical Applications

The 8D problem-solving process stands as a beacon of structured analysis and corrective action within the complexities of operational pitfalls and quality control discrepancies across industries. Originating from the automotive industry and since adopted widely, the methodology offers a meticulous step-by-step approach that fosters team cohesion, addresses problems at their roots, and implements sustainable solutions.

This article seeks to delve into the nuances of the 8D problem-solving framework, presenting a lucid exposition of its origins, a detailed foray into each step enriched by practical examples, and concluding with the unequivocal benefit bouquet it presents to the organization adopting it.

The Origins of the 8D Problem Solving Methodology

The 8D, or "Eight Disciplines," problem-solving approach germinated from the fertile grounds of collaborative efforts to ensure superior quality and reliability in manufacturing. Initially developed by the Ford Motor Company in the 1980s, this systematic method was a response to a confluence of quality and operational issues that were pervasive in the automotive industry. It drew broader appeal as its efficacy became apparent - functioning as an amalgam of logic, analytics, and teamwork to tackle problems methodically.

The wide reach of the 8D methodology is evident in industries ranging from manufacturing to healthcare, aerospace to IT, and beyond. Its universal applicability stems from a foundational adherence to principle over process, transcending the intricacies of industry-specific challenges. By combining reactive and proactive measures, the 8D method helps in not just extinguishing the fire, but also preventing its outbreak, making it an enduring asset in the organizational toolkit.

The 8 Steps of Problem Solving

An incursion into the 8D methodology reveals a framework that is both systematic and flexible. Each step is sequenced to ensure that issues are not merely patched but genuinely resolved, implementing robust preventive measures to curtail recurrences. This section expounds on each disciplinary step and serves as a substrate for practical implementation examples, supplementing theoretical insights with real-world applicability.

Step 1: Establish a Team

The cornerstone of any formidable 8D approach begins with assembling a competent team. The wisdom embedded in this initial phase is the recognition that effective problem-solving is not a solitary venture but a collaborative pursuit. A multidisciplinary team brings diverse perspectives that are critical in diagnosing issues accurately and devising solutions effectively.

When determining team composition, the emphasis should be on a mix of skills and expertise relevant to the problem at hand. Roles within the team should be clearly defined to streamline activities and foster accountability. Each member should be well-versed in their responsibilities, from those leading the problem-solving charge to those executing and tracking actions.

Step 2: Describe the Problem

Clarity is vital in the second step, which necessitates delineating the problem with precision. A meticulous description sets the foundation for targeted analysis and actionable solutions. It involves accruing information that is factual, quantifiable, and devoid of assumptions – the cornerstone of an accurate problem portrayal.

Techniques like '5W2H' (who, what, when, where, why, how, how much) can galvanize teams into crafting detailed problem descriptions. An exemplar of a well-articulated problem statement might state, "Machine X has experienced a 15% decline in output quality, resulting in a monthly loss of 200 units of product Y since January due to recurrent mechanical inaccuracies."

Step 3: Develop Interim Containment Actions

Addressing a problem's immediate impact is pivotal to prevent exacerbation as a root cause analysis is conducted. Interim containment actions can be likened to first aid – essential, though not the definitive cure. These measures should be rigorously designed to quell the problem's spread or intensification without creating new issues.

An interim action for the aforementioned issue with Machine X could involve adjusting the production schedule to mitigate output loss while the machine is under examination. This demonstrates a temperate solution, buying time for a comprehensive fix without severely disrupting the production chain.

Step 4: Define and Verify the Root Cause(s)

Singular in its focus yet pluralistic in its approach, this phase is committed to uncovering the underlying reasons for the problem. Root cause identification is a task of surgical precision, necessitating a deep dive into the problem without the constraints of predetermined notions.

Techniques such as the "5 Whys" and "Fishbone Diagram" guide problem solvers through a structured investigation of potential causes. Verification is as crucial as identification, ensuring that purported root causes stand up to scrutiny and testing.

Step 5: Verify Permanent Corrective Action(s)

Once root causes have been established, attention shifts to devising and validating long-term corrective actions. This step traverses the path from theory to practice. It requires a judicious appraisal of potential solutions with a clear-eyed view of their feasibility, effectiveness, and sustainability.

Best practices in this step incorporate piloting solutions on a smaller scale, enabling refinement before full-scale implementation. A well-considered corrective action for Machine X might involve upgrading mechanical components identified as failure points, subject to cost-benefit analysis and potential disruption to the production line.

Step 6: Implementing and Validating Permanent Corrective Actions

This step transitions the plan into reality, pushing the corrective actions beyond the threshold into the operational environment. Careful implementation is the linchpin, with detailed plans and schedules ensuring that actions are well-executed and efficacious.

The validation process is a keystone in affirming that corrective actions deliver the intended improvements. For Machine X, this could entail monitoring post-repair performance metrics over a defined period against pre-issue levels to authenticate the efficacy of the improvements.

Step 7: Preventive Measures

Armed with insights gleaned, the 7th step propels the methodology into preventative mode. Here, the onus is on forestalling a problem’s resurgence by ingraining the lessons learned into the organizational fabric. The aim is to encapsulate these insights in policies, procedures, or system changes.

This could mean revising maintenance schedules or worker training programs for Machine X to include the specific nuances that led to the mechanical inaccuracies, thereby shielding against repeat episodes.

Step 8: Congratulate Your Team

The final step encompasses a human-centered focus on recognition and commendation. Acknowledgment of the team’s efforts reinforces motivation, fosters a positive culture, and encourages engagement in future problem-solving initiatives.

Celebrating the success could manifest in a ceremonious recognition of the team’s achievements, an internal announcement of their contributions, or a tangible expression of appreciation. This not only cements the accomplishment but also propels a sense of camaraderie and collective purpose.

The Importance of the 8D Problem Solving Process

A mature consideration of the 8D problem-solving process corroborates its contributory significance in unraveling complex issues and instituting consequential improvements. The benefits it confers are manifest in enhanced product quality, heightened customer satisfaction, and the stimulation of a proactive problem-solving culture. Challenges do persist, mainly in the form of resistance to change or insufficient training; nevertheless, with a conscientious implementation, these can be navigated.

Moreover, the 8D approach aligns seamlessly with the pursuit of continuous improvement – a cornerstone of many business philosophies such as Lean and Six Sigma. It thus serves not only as a solution framework but also as a catalyst for organizational growth and learning.

In summary, the 8D problem-solving methodology stands out for its disciplined, team-driven, and methodical approach to tackling complex problems. From its historical roots in the automotive industry to its implementation in modern enterprises, its efficacy in achieving sustainable solutions is undoubted. Online certificate programs and problem-solving courses often feature 8D due to its relevance and value across industries.

As this article delineates each step, with practical applications and advice, the message is clear: mastery of 8D is not just for immediate problem resolution – it is a pathway to building a resilient and adaptive organization capable of facing the challenges of an ever-changing business landscape.

What are the key steps involved in the 8D Problem Solving process and how do they interact with each other?

Introduction to the 8d process.

The 8D Problem Solving process stands tall. It is a structured approach. Businesses use it widely. 8D tackles complex problems effectively. It drives teams towards lasting solutions. It also fosters quality and reliability. The "D" denotes eight disciplined steps. These steps guide teams. They identify, correct, and prevent issues.

8D Steps Explained

D1: establish the team.

Form a skilled team first. Diversity matters here. Each member brings insights. Their combined expertise is crucial. Team formation kicks off the process.

D2: Describe the Problem

Articulate the issue clearly. Use quantifiable data here. Understanding the scope matters. Have accurate problem statements ready. They pave the way forward.

D3: Develop Interim Containment Action

Ensure a temporary fix. It limits the problem's impact. Speed is of the essence. However, ensure the action is effective. The goal is to stabilize the situation.

D4: Determine Root Cause

Dig deep into causes. Use data-driven analysis. Techniques include fishbone diagrams. Five Whys is also popular. Root cause analysis is pivotal. It prepares the team for corrective actions.

D5: Design and Verify Permanent Corrective Actions

Choose the best corrective action. Rigorous selection criteria apply. Effectiveness and efficiency matter. Verify through testing. Make certain the solution fits.

D6: Implement and Validate Permanent Corrective Actions

Roll out the solution. Watch closely for results. Validation takes place here. Use performance indicators for this. They must indicate that the solution works.

D7: Prevent Recurrence

Embed the improvement. Update systems and policies. Training may be necessary. Maintain the gains. This step safeguards the future. Documentation is important here.

D8: Congratulate the Team

Never overlook recognition. Acknowledge everyone's efforts. Celebrate the success achieved. It boosts team morale. It also promotes a culture of quality.

Interplay Between Steps

The interdependence is strong. Each step builds on the previous one. For example, a strong team in D1 enhances problem understanding in D2. Similarly, effective interim actions in D3 set the stage for a thorough root cause analysis in D4.

The verification in D5 ensures the solution from D4 is sound. Implementation in D6 then relies on the verified action. To prevent recurrence (D7), one must understand the root cause. The entire process relies on clear communication. Team recognition (D8) closes the loop neatly. It paves the way for future problem-solving success.

In essence, the 8D steps are interlinked. Each step informs the next. Teams achieve the best results by following the sequence. They also adapt as needed. 8D enforces a discipline that leads to high-quality results. The interaction between steps ensures problems do not just disappear. They stay solved. This is the power of an integrated problem-solving approach.

Can you provide some practical examples of the effective application of 8D Problem Solving strategies in real-life settings?

Understanding 8d problem solving.

8D problem solving stands for Eight Disciplines. It involves steps that teams must follow. Starting from identifying problems , it goes until preventing reoccurrences . Companies use 8D to tackle complex issues. Its main goal remains quality improvement.

Here are practical examples where 8D shines.

Example 1: Automotive Industry

D0: Plan - An auto manufacturer formed a team. Their goal was clear: resolve brake failures.

D1: Team Formation - They gathered experts from diverse fields. Collaboration was key here.

D2: Describe the Problem - They identified specific issues. Customers reported brakes failing at high speeds.

D3: Develop Interim Containment - They distributed quick-fix kits to dealerships. This ensured immediate customer safety.

D4: Determine Root Causes - A deep dive ensued. The team discovered a faulty brake fluid line.

D5: Choose and Verify Permanent Corrective Actions (PCAs) - They redesigned the brake line. Then they tested it under rigorous conditions.

D6: Implement and Validate PCAs - The new design went into production. Ongoing assessments confirmed its effectiveness.

D7: Take Preventive Measures - They updated their design guidelines. Thus, they eliminated the possibility of similar failures.

D8: Congratulate Your Team - Management recognized the team's effort. This promoted a culture of problem-solving.

Example 2: Electronics Manufacturer

D0: Plan - A sudden surge in returned gadgets prompted action.

D1: Team Formation - A cross-functional team took charge. They had one aim: find the flaw.

D2: Describe the Problem - Devices were overheating during usage. Anxiety among customers grew.

D3: Develop Interim Containment - They halted the production line. Assessing risks was necessary.

D4: Determine Root Causes - Detailed analysis revealed a substandard battery component.

D5: Choose and Verify PCAs - They sourced a higher quality component. Subsequent tests showed promising results.

D6: Implement and Validate PCAs - They integrated the new component into production. Monitoring phases ensured it was a fix.

D7: Take Preventive Measures - They revamped their quality control protocols. Now they could avoid similar issues.

D8: Congratulate Your Team - The team's innovative approach earned praise. They set new standards in their processes.

Example 3: Food Packaging Company

D0: Plan - Reports of packaging leaks triggered an 8D.

D1: Team Formation - Experts from production to distribution joined forces. They understood the stakes were high.

D2: Describe the Problem - The leaks were sporadic but damaging. Food safety concerns escalated.

D3: Develop Interim Containment - They removed compromised products from shelves. Protecting the consumer was paramount.

D4: Determine Root Causes - Investigation exposed a sealing machine defect.

D5: Choose and Verify PCAs - Engineers redesigned the sealing mechanism. Trials followed, proving success.

D6: Implement and Validate PCAs - The updated machines replaced the old ones. Continuous evaluations followed to assure quality.

D7: Take Preventive Measures - They introduced more rigorous maintenance routines. They aimed to preempt future failures.

D8: Congratulate Your Team - The swift and thorough response earned accolades. They reinforced trust in their brand.

8D's Practical Value

Each example showcases 8D's potential. This problem-solving framework adapts to various scenarios. Through structured teamwork and analysis, it guides toward sustainable solutions. It helps in ensuring the same problem does not occur twice. Businesses across different sectors find 8D crucial for their continuous improvement efforts. It underlines that a methodical approach to problem-solving can yield significant long-term benefits.

How is the effectiveness and success of the 8D Problem Solving approach measured in practical applications?

Introduction to 8d problem solving.

The 8D Problem Solving approach stands as a structured methodology. It aims to address and resolve critical issues within an organization. Rooted in the team-oriented approach, 8D follows eight disciplined steps. These steps ensure a comprehensive and effective resolution process. The process includes identifying the problem, implementing interim controls, defining root causes, developing a corrective action plan, taking corrective actions, validating those actions, preventing recurrence, and finally congratulating the team.

Measuring Effectiveness and Success

Quantitative metrics.

Timeliness of Response

The promptness of the initial response is critical. It alerts stakeholders to the emergence and acknowledgment of the issue.

Problem Recurrence Rates

A key success indicator is the frequency of problem recurrence. A declining trend signifies effective corrective actions.

Financial Impact

Cost savings or avoidance measures the fiscal efficiency of the resolution. It counts both direct and indirect factors.

Cycle Time Reduction

Improvements in processes can lead to shorter cycle times. This reflects efficiency gains from the 8D implementation.

Qualitative Metrics

Quality of Documentation

Comprehensive documentation ensures thorough issue analysis. It captures the nuances of the problem-solving journey.

Stakeholder Satisfaction

Feedback from affected parties gauges the outcome’s acceptability. Satisfaction levels can direct future interventions.

Knowledge Transfer

Disseminating learnings enhances organizational capability. Sharing insights leads to broader, preventive measures.

Team Cohesion and Growth

Personal and team development signal process benefits. Such growth provides intangible value to the organization.

Practical Application and Continuous Improvement

In practical applications, tailoring metrics to contexts is vital. Unique business environments demand specific success criteria. Therefore, adapting the approach and its measurement system is necessary.

Organizations may employ a combination of tangible and intangible metrics. Aligning these to strategic goals ensures relevance. The 8D Process receives fine-tuning through iterative cycles. Each cycle offers an opportunity for enhanced problem-solving efficacy.

The Importance of Measure Standardization

Standardizing the measurement process ensures consistency. It aids in comparing and benchmarking against best practices. Homogeneity in measures facilitates clearer communication. It enhances the understanding of successes and areas for improvement.

Revisiting and Refining the 8D Process

Upon completion, a rigorous review of the 8D process is crucial. It ensures learnings lead to process refinement. Alterations in measures might follow to better reflect evolving business needs. This ongoing evolution drives the sustained value of the 8D methodology.

The 8D Problem Solving approach, with its disciplined steps, delivers a robust framework. Measuring its effectiveness requires a blend of quantitative and qualitative metrics. These metrics, when standardized and continually refined, offer a clear lens to assess the 8D process's success. They help organizations not just to solve problems but to evolve in their problem-solving capabilities.

He is a content producer who specializes in blog content. He has a master's degree in business administration and he lives in the Netherlands.

Decision Tree: A Strategic Approach for Effective Decision Making

Lateral Thinking for Problem-Solving: Find the Haystack!

Unlocking Problem Solving Skills: Where Do Problems Come From?

Developing Problem Solving Skills Since 1960s WSEIAC Report

8D Chess: How to Use The 8 Disciplines for Problem Solving

Hospitals have developed something of a reputation for being rife with bad processes . When processes aren’t adequate, the result is an abundance of “workarounds”.

For example, when equipment or supplies are missing, a nurse might waste time running around searching for what is needed, and once the item is found, return to their previous duties.

One study indicates that nurses spend 33 minutes of a 7.5-hour shift completing workarounds that are not part of their job description.

This may well “put out the fire” so-to-speak, but really it is just a hastily applied band-aid that does nothing to treat the root cause of the problem.

More time is wasted and more problems will arise in the future because nothing has been done to prevent the initial problem from happening again.

Individual nurses are not at fault here; workplace culture often values expertise in the form of those who “get the job done”, which tends to pull against the notion of spending time building good processes (time in which the job is perhaps not “getting done”).

So how to approach the problem of problem solving ?

In a lean context, problem solving can be distilled into two simple questions:

- What is the problem and how did it happen?

- How can we make sure that it doesn’t happen again?

The 8D, or eight disciplines methodology, is a problem solving process – most likely one of the most widely used problem solving processes out there. It is used by many different countries, in many different industries, and many different organizations.

8D is designed to help you put out those fires, and make sure they don’t happen again.

In this article, I’ll introduce you to the 8D problem solving methodology and provide you with an outline of the basic process that you can hopefully apply in your own business, plus how you can enhance 8D with other tools and methodologies like Six Sigma , FMEA , and Process Street .

Here’s what I hope you’ll take away after reading:

- An understanding of the basics of 8D

- Advantages of using 8D

- The purpose and objectives of each phase of the 8D process

- An understanding of how to use 8D for problem solving

- How 8D works with other problem solving tools

- How you can use Process Street to maximize the potential of the 8D framework

Let’s begin with the origins of 8D – what is it, and where did it come from?

What is 8D?

8D (sometimes Global 8D or G8D) stands for eight disciplines, and is a problem solving methodology. It’s basically a process for understanding and preventing problems.

Much like how risk management seeks to take a proactive, preventative stance, 8D aims to gain insight into the root causes of why the problems happen, so they won’t happen again.

The 8D process involves eight (sometimes nine) steps to solve difficult, recurring problems. It’s a transparent, team-based approach that will help you solve more problems in your business.

8D origins: Where did it come from?

Despite the popular story that 8D originated at Ford, it was in fact developed in 1974 by the US Department of Defence, ultimately taking the form of the military standard 1520 Corrective Action and Disposition System for Nonconforming Material .

Ford took this military standard, which was essentially a process for quality management , and expanded on it to include more robust problem solving methods.

In 1987, Ford Motor Company published their manual, Team Oriented Problem Solving (TOPS) , which included their first iteration of the 8D methodology.

Initially termed Global 8D (or G8D) standard, it is currently used by Ford and many other companies in the automotive supply chain.

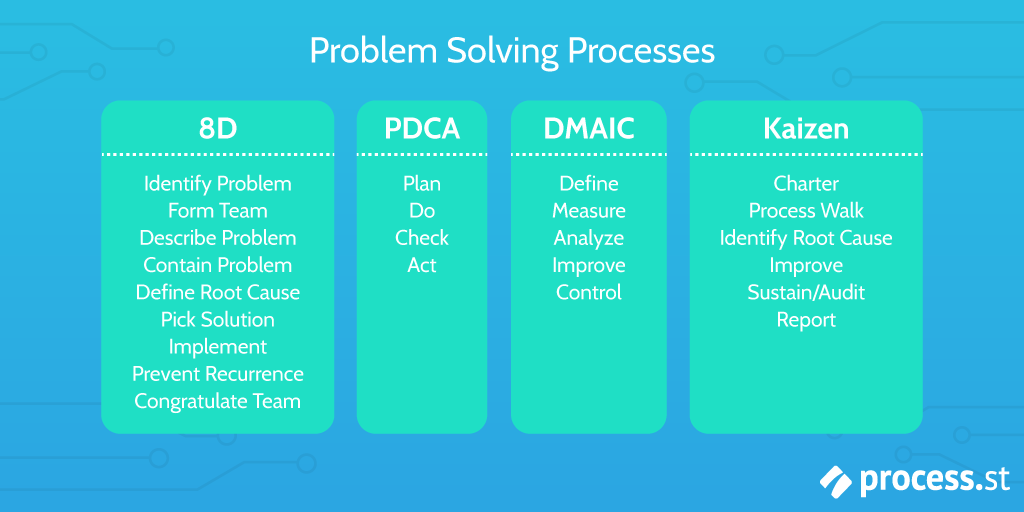

8D, PDSA, & other problem solving processes

The disciplines of 8D follow the same logic as the Deming Cycle (also known as PDSA, and sometimes PDCA).

PDSA stands for Plan, Do, Study, Act (or Check, in the case of PDCA).

The similarity lies in the fact that both PDSA and 8D are designed to be used to improve processes. They’re both examples of cycles of continuous improvement.

Whereas 8D may be painted as a more generic problem-solving framework, structurally speaking both 8D and PDSA share a lot in common.

The simple idea of beginning with a clear objective, or desired output, and then testing, analyzing , and iteratively tweaking in a continuous cycle is the basis for both methodologies.

There are, of course, differences. We’ll cover the different applications of both 8D and PDSA in this article.

8D advantages

One of the main strengths of 8D is its focus on teamwork. 8D philosophy encourages the idea that teams, as a whole, are more powerful than the sum of the individual qualities of each team member.

It’s also an empirical methodology; that is to say that it is a fact-based problem solving process.

A branch of continuous improvement, proper use of 8D will help you coordinate your entire team for effective problem solving and improved implementation of just about all of the processes used in your business.

The 8 disciplines for problem solving

As you may have noticed, we’re starting with zero, which makes nine total disciplines. This “zero” stage was developed as an initial planning step.

D0: Plan adequately

Make comprehensive plans for solving the problem including any prerequisites you might determine.

Be sure to include emergency response actions.

D1: Establish your team

Establish your core team with relevant product or process knowledge. This team will provide you with the perspective and ideas needed for the problem solving process.

The team should consist of about five people, from various cross-functional departments. All individuals should have relevant process knowledge.

A varied group will offer you a variety of different perspectives from which to observe the problem.

It is advisable to establish team structure, roles, and objectives as far ahead in advance as possible so that corrective action can begin as quickly and effectively as possible.

D2: Describe the problem

Have your team gather information and data related to the problem or symptom. Using clear, quantifiable terms, unpack the problem by asking:

D3: Contain the problem (temporary damage control)

Depending on the circumstances, you may need to mobilize some kind of temporary fix, or “firefighting”.

The focus of this stage should be on preventing the problem from getting worse, until a more permanent solution can be identified and implemented.

D4: Identify, describe, and verify root causes

In preparation for permanent corrective action, you must identify, describe, and verify all possible causes that could contribute to the problem happening.

You can use various techniques for this, including a Failure Modes and Effects Analysis , or Ishikawa (fishbone) diagram .

It’s important that the root causes are systematically identified, described in detail, and promptly verified (or proved). How each cause is verified will depend on the data type and the nature of the problem.

Take a look at the section towards the end of this article for some more problem solving tools to help you decide the right approach.

D5: Identify corrective actions

You must verify that the corrective action you identified will in fact solve the problem and prevent it from happening again in the future (or whatever is your desired threshold of recurrence).

The best way to do this is to collect as much data as possible and by performing smaller-scale “pilot” tests to get an idea of the corrective action’s impact.

You can’t begin to identify the optimal corrective action until you have identified the root cause(s) of the problem.

D6: Implement and validate corrective actions

Carry out the corrective actions, and monitor short and long term effects. During this stage, you should assess and validate the corrective actions with empirical evidence.

Discuss and review results with your team.

D7: Take preventative measures (to avoid the problem happening again)

Here is where you make any necessary changes to your processes, standard operating procedures , policies , and anything else to make sure the problem does not happen again.

It may not be possible to completely eliminate any chance of the problem recurring; in that case, efforts should focus on minimizing possibility of recurrence as much as possible.

D8: Congratulate your team

It’s important to recognize the joint contribution of each and every one of the individuals that were involved in the process.

Team members should feel valued and rewarded for their efforts; this is crucial and perhaps the most important step – after all, without the team, the problem would not have been fixed.

Providing positive feedback and expressing appreciation helps to keep motivation high, which in turn improves the sense of process ownership and simply increases the likelihood your team will actually want to improve internal processes in the future.

How to use 8D for problem solving

The 8D method above outlines a proven strategy for identifying and dealing with problems. It’s an effective problem solving and problem prevention process.

In addition to avoiding long-term damage from recurring problems, 8D also helps to mitigate customer impact as much as possible.

More than just a problem-solving methodology, 8D sits alongside Six Sigma and other lean frameworks and can easily be integrated with them to minimize training and maximize efficacy.

8D is definitely a powerful framework on its own, but it really shines when combined with other synergistic concepts of lean and continuous improvement.

More problem solving tools that synergize well with 8D

8D has become a leading framework for process improvement, and in many ways it is more prescriptive and robust than other more simplistic Six Sigma approaches.

However, there are many Six Sigma methodologies, and even more frameworks for problem solving and process improvement .

The following improvement tools are often used within or alongside the 8D methodology.

DMAIC: Lean Six Sigma

DMAIC stands for:

The DMAIC process is a data-driven cycle of process improvement designed for businesses to help identify flaws or inefficiencies in processes.

Simply put, the goal with DMAIC is to improve and optimize existing processes.

Interestingly, the development of the DMAIC framework is credited to Motorola , whose work built upon the systems initially developed by Toyota .

In terms of working alongside 8D, you could use DMAIC to identify root causes as in D4; you could also implement the same techniques to better understand prospects for corrective actions as in D5, and D6.

We have a whole article on the DMAIC process, if you’re interested.

SWOT analysis

Strengths, Weaknesses, Opportunities, and Threats. You can use a SWOT analysis to gain insight into your organization as a whole, or on individual processes.

The main synergy with 8D is in the identification of opportunities, threats, and weaknesses.

These can represent opportunities for process improvements, weaknesses in your process that could produce problems further down the line, and threats, both internal and external, that may be out of your direct control but that could cause problems for you.

Here’s a SWOT analysis checklist you can use to structure your own analysis:

FMEA: Failure Mode and Effects Analysis

FMEA (Failure Mode and Effects Analysis) is a way of understanding the potential for problems and making preemptive preparations in order to avoid them. It is a method of risk management .

It is a type of preventative risk management process, and so works well in the context of identifying causes of problems so you can better deal with them.

FMEA and 8D work well together because:

- 8D can make use of information gathered during an FMEA process, like brainstorming sessions, to identify potential problems and their root causes.

- You can reuse possible cause information gathered during an FMEA process to feed into different representational diagrams like the Ishikawa (fishbone) diagram, which will help in the 8D process.

- 8D brainstorming data is useful for new process design. This allows the FMEA to take actual process failures into account, which produces more effective results.

- FMEA completed in the past can be used as databases of potential root causes of problems to inform 8D process development.

Here’s a free FMEA template for you to get started ASAP:

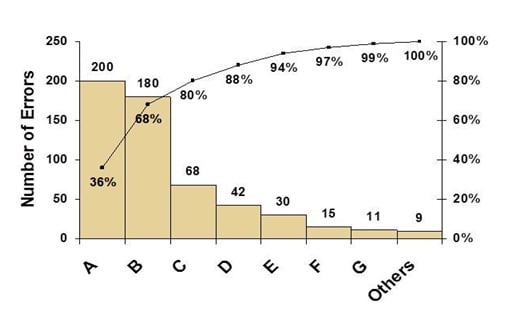

The Pareto Chart

The Pareto Chart helps us understand the impact of different variations of input on our output.

In relation to 8D, Pareto Charts can help us prioritize which root cause to target, based on which will have the greatest impact on improvement (where improvement is the desired output of the 8D process).

Here’s the Six Sigma Institute’s example Pareto Chart :

Here we have a simple deductive reasoning technique that asks “why?” five times to dig into the root cause of a problem.

The logic here is that by asking the same question five times, you work progressively “deeper” into the complexity of the problem from a single point of focus.

Ideally, by the fifth question you should have something that has a high likelihood of being a root cause.

This example from Wikipedia does a great job of conveying how the process works:

- The vehicle will not start. (the problem)

- Why? – The battery is dead. (First why)

- Why? – The alternator is not functioning. (Second why)

- Why? – The alternator belt has broken. (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced. (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule. (Fifth why, a root cause)

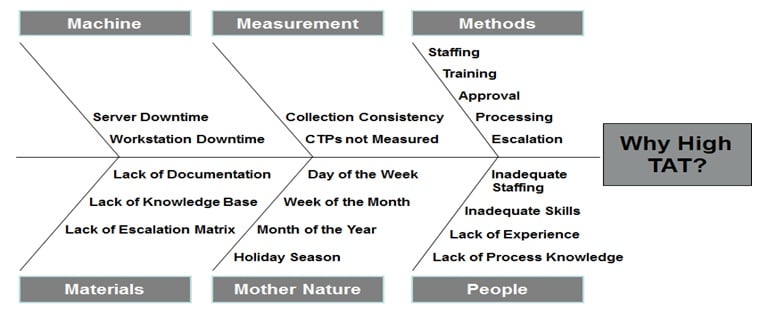

Ishikawa diagrams (fishbone diagrams)

Sometimes called “cause-and-effect diagrams”, they are as such used to visualize the cause and effect of problems.

The approach takes six different categories and places information about the problem into different categories to help you understand what factors could be contributing to the problem.

One advantage over the 5 Whys approach is the way this method forces a more holistic perspective, as opposed to the potentially narrow vantage point offered by zooming in on a single aspect or question.

According to the Six Sigma Institute, the 6 key variables pertaining to root causes of problems are:

- Machine: Root causes related to tools used to execute the process.

- Material: Root causes related to information and forms needed to execute the process.

- Nature: Root causes related to our work environment, market conditions, and regulatory issues.

- Measure: Root causes related to the process measurement.

- Method: Root causes related to procedures, hand-offs, input-output issues.

- People: Root causes related people and organizations.

There’s also this useful illustration of a company using a fishbone diagram to better understand what factors contribute to a company’s high turn around time.

Gap analysis

A gap analysis is concerned with three key elements:

- The current situation, or “performance”

- The ideal situation, or “potential”

- What needs to be done in order to get from performance to potential, or “bridging the gap”

The “gap” is what separates your current situation from your ideal situation.

Businesses that perform a gap analysis can improve their efficiency and better understand how to improve processes and products.

They can help to better optimize how time, money, and human resources are spent in business.

There’s a lot that goes into a gap analysis, and quite a few different ways to approach it. Check out our article for a deeper dive into the gap analysis process.

Superpowered checklists

Checklists can be a great way to simplify a complex process into a series of smaller, easy-to-manage tasks. They’re one of the best ways to start using processes in your business.

By using checklists, you can reduce the amount of error in your workflow , while saving time and money by eliminating confusion and uncertainty.

What’s more, if you’re using Process Street, you have access to advanced features like conditional logic , rich form fields and streamlined template editing .

How to use Process Street for 8D problem solving

Good problem solving relies on good process. If you’re trying to solve problems effectively, the last thing you want is your tools getting in your way.

What you want is a seamless experience from start to finish of the 8D methodology.

The best kinds of processes are actionable. That’s why you should consider using a BPM software like Process Street to streamline recurring tasks and eliminate manual work with automation .

Process Street’s mission statement is to make recurring work fun, fast, and faultless. By breaking down a process into bite-sized tasks , you can get more done and stay on top of your workload.

Sign up today for a free Process Street trial!

Problem solving is an invaluable skill. What’s your go-to process for problem solving? We’d love to know how it compares with the 8D method. Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Oliver Peterson

Oliver Peterson is a content writer for Process Street with an interest in systems and processes, attempting to use them as tools for taking apart problems and gaining insight into building robust, lasting solutions.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- Customer Login

- Android App

- Help Center

- Terms of Service

- Privacy Policy

- Support Policy

Kaizen for Everyone

+1 (888) 551-5917 [email protected].

Rever, 68 Willow Road, Menlo Park, CA. 94025, United States. Copyright ©2018 Rever, Inc. All Rights Reserved.

8D Problem Solving | How We Leverage The 8 Disciplines

Posted on September 6, 2019

BY Borja Gomez

8 minutes, 21 seconds read

The 8D problem-solving model is an invaluable tool for when things go wrong or need to be improved. It’s a collaborative and methodical approach to addressing critical problems, often used to enhance production processes. It does this by facilitating root cause analysis, containment plan development, and corrective solution implementation.

When it comes to manufacturing, service delivery, or any number of other disciplines, problems will occur. It’s common for businesses to experience issues with product quality, process changes, or scaling their operations. Recurring problems cost businesses money, use up resources, and decrease efficiency. These issues can also frustrate customers, disengage team members, and concern shareholders, so it’s crucial to address them quickly and that is exactly what 8d does.

In order to resolve issues and drive improvement , it’s important to understand what’s at the core and then be proactive in addressing it. Whether you need to identify the root cause of a problem, take short-term corrective actions, or implement a permanent long-term solution, the 8D method can help. In this article, we explore how, when, and why to use the 8D problem-solving approach.

What is 8D Problem Solving?

8D problem solving is a practical approach to addressing negative issues in business. The ‘8D’ stands for ‘eight disciplines’ which provide a structured framework that project teams can work through. By following the analysis and steps that it outlines, organizations can solve problems that are critical to operations or particularly challenging.

This model was initially used by the US military during the Second World War. It was known as the ‘Team Oriented Problem Solving’ (TOPS) method which Ford Motors later popularized. The automotive manufacturer refined the process and tools. It was then renamed to the Eight Disciplines (8D) of Problem Solving. 8D is sometimes confused as a lean six sigma tool but it actually isn’t one. However, 8D can be useful in Kaizen continuous improvement efforts and striving towards lean processes.

Why Use These 8 Disciplines?

The goal of 8D problem solving and 8D methodology is to contain and solve the primary root causes of a problem and state corrective actions for problem solving. 8D provides a framework for undertaking the initial analysis to get the right data and information, pilot testing, and final execution of a solution. Addressing issues in this way is beneficial for a number of reasons;

- Containment – the eight disciplines problem-solving approach allows you to first contain the issue at it’s cause so that its negative effects are mitigated.

- Root cause analysis (RCA) – it then enables you to identify the core of the problem so that an effective solution can be found and repetitions of the issue are avoided.

- Increases successful outcomes – using a proven framework like 8D problem-solving increases the likelihood that an issue will be solved successfully and for the long term.

- Efficiency – the 8D model identifies causes that can negatively impact efficiency and productivity so that businesses operate to their fullest potential.